Non-well killing well mouth operation process and equipment of injection-production integrated thermal production process

A technology of thermal recovery technology and operation technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of no public documents found, no snubbing operation, and can not be realized, so as to avoid cooling damage and Formation cold damage, huge economic benefits, and the effect of meeting the requirements of secondary well control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

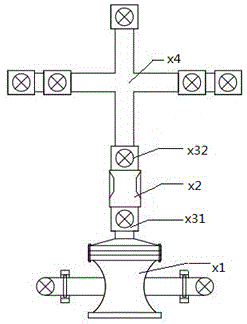

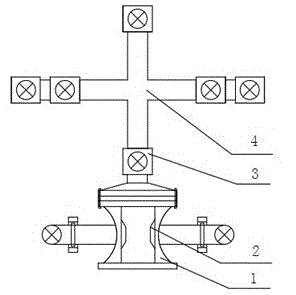

[0025] figure 2 , a kind of snubbing steam injection wellhead equipment for injection-production integrated thermal recovery process, comprising a large cross 1, an upper half set 4 of a steam injection wellhead, and a hollow rod hanger 2, the upper end of the large cross passes through a main gate 3 and The upper half of the steam injection wellhead is connected, and the hollow rod hanger is arranged inside the large cross. When the hollow rod hanger is used for steam injection, the hollow rod with pump is connected to a hollow rod seat to hang the joint seat on the hollow rod hanger, and the diameter of the hollow rod hanger does not exceed the diameter of the total gate.

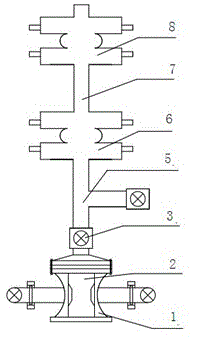

[0026] image 3 , a kind of injection-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com