Drilling pressure relief control method of longwall-face mining roadway with deformed forepole support sections

A technology of mining roadway and advanced support, which is applied in drilling equipment and methods, ground mining, earth-moving drilling, etc., can solve the problems of high labor intensity, low efficiency, frequent movement of drilling rigs, etc., and achieve the effect of improving fracturing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

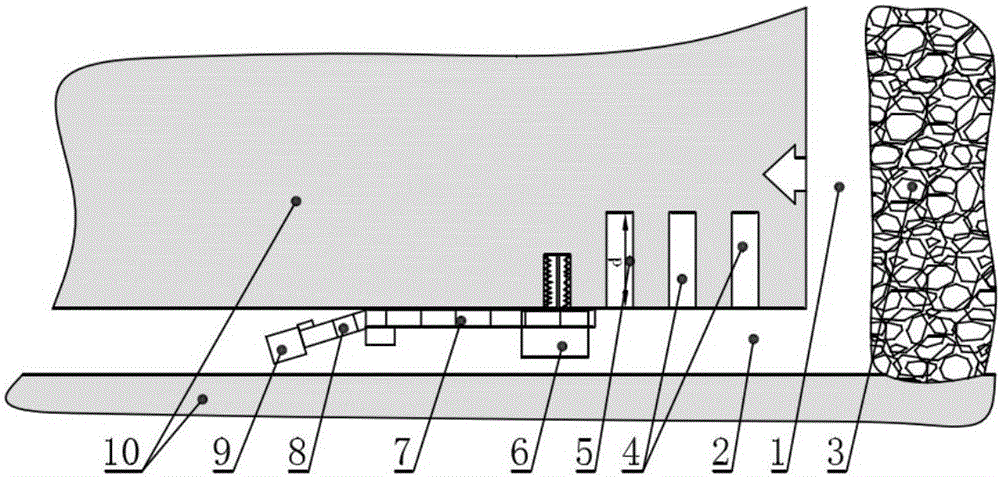

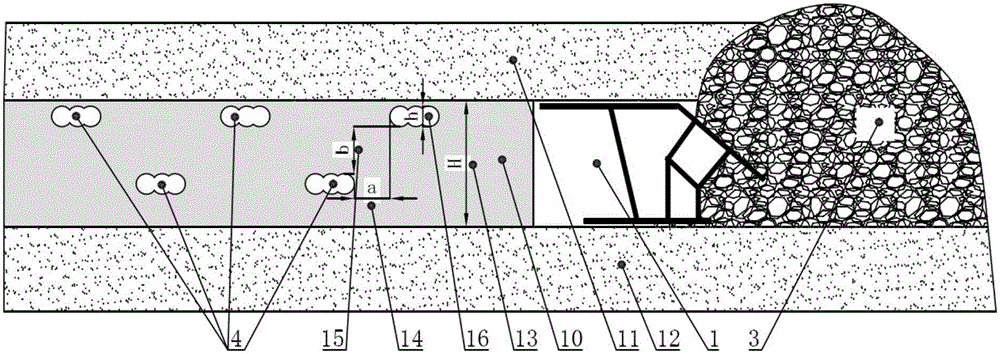

[0029] Embodiment 1: The drilling-production pressure relief control method of the deformation of the advanced support section of the longwall working face mining roadway of the present invention, the implementation process mainly includes three aspects: the design of drilling parameters, the design of the drilling-production system and the selection of equipment, and Drilling technology design and construction.

[0030] Design of drilling parameters: According to the conditions of the coal seam 10 and the design parameters of the roadway 2, the depth d 5 of the drilling 4, the horizontal distance w 14 of the drilling and the vertical distance h 15 between the drillings are determined.

[0031] Drilling and mining system design and equipment selection: According to the section size of the roadway 2 and the conditions of the bottom plate 12, determine the composition of the drilling and mining coal transportation system and the parameters and parameters of the auger shearer 6, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com