A manufacturing process of a fire-resistant breathing unit for ships

A fire-stopping and ship-building technology, which is applied in the field of ship parts and components, can solve problems such as the inability to ensure the normal breathing of oil tanks, achieve good economic and social benefits, and prevent flames from crossing each other.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

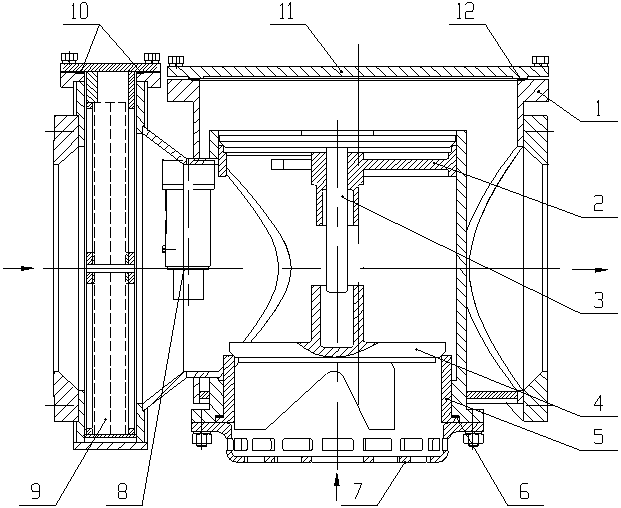

Embodiment 1

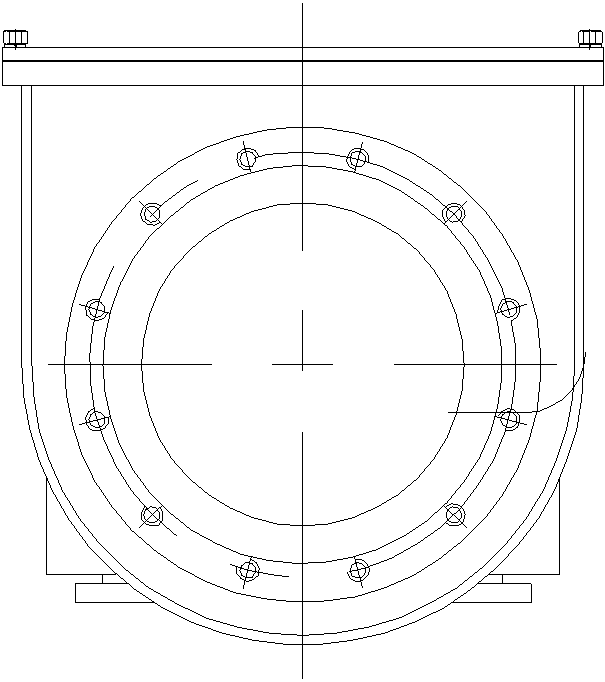

[0051] Embodiment 1, the calculation of the flow area of the fire-blocking core layer of the fire-blocking assembly 9, the ventilation rate: ≥760 m³ / h, assuming that the gas flow rate is 7.5m / s (GJB4000 "General Specifications for Ships" 507.8.13 article: the flow rate in the air pipe No more than 7.6m / s); required flow area: 28148.15mm²; flow ratio of fire-resistant core layer: 0.38; diameter of fire-resistant core layer: 320mm (calculated as 307.11mm).

Embodiment 2

[0052] Embodiment 2, the sealing surface grinding technology, the fire retardant breathing unit is in the closed state, there should be no leakage, the surface roughness of the metal sealing surface is highly required, and the surface roughness determines the sealing performance of the product. The metal sealing surface must be ground to achieve Sealing performance requirements, adopt the following measures to ensure surface accuracy, 1) use wire seal; 2) ensure the surface roughness of the sealing surface during processing; 3) conduct research on the sealing surface; 4) correctly select abrasives; 5) use Appropriate grinding process; 6) After grinding, compare the grinding surface with a sample block for testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com