Sealing structure for plastic steel faucet

A sealing structure and faucet technology, which is applied in the field of faucets, can solve the problems of easy accumulation of scale, difficult casting technology, and reduced service life of faucets, etc., and achieve the effect of practical and reliable structure, beautiful appearance and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

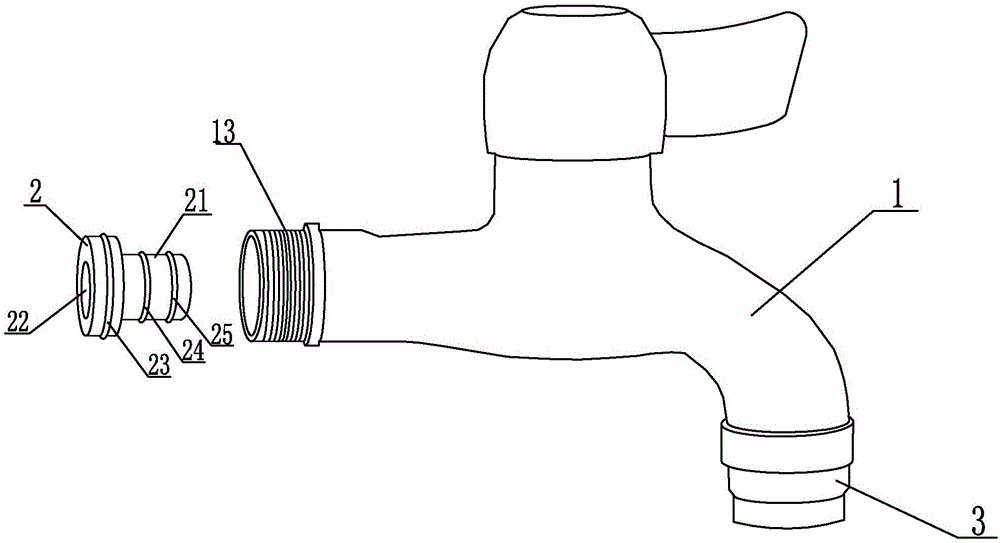

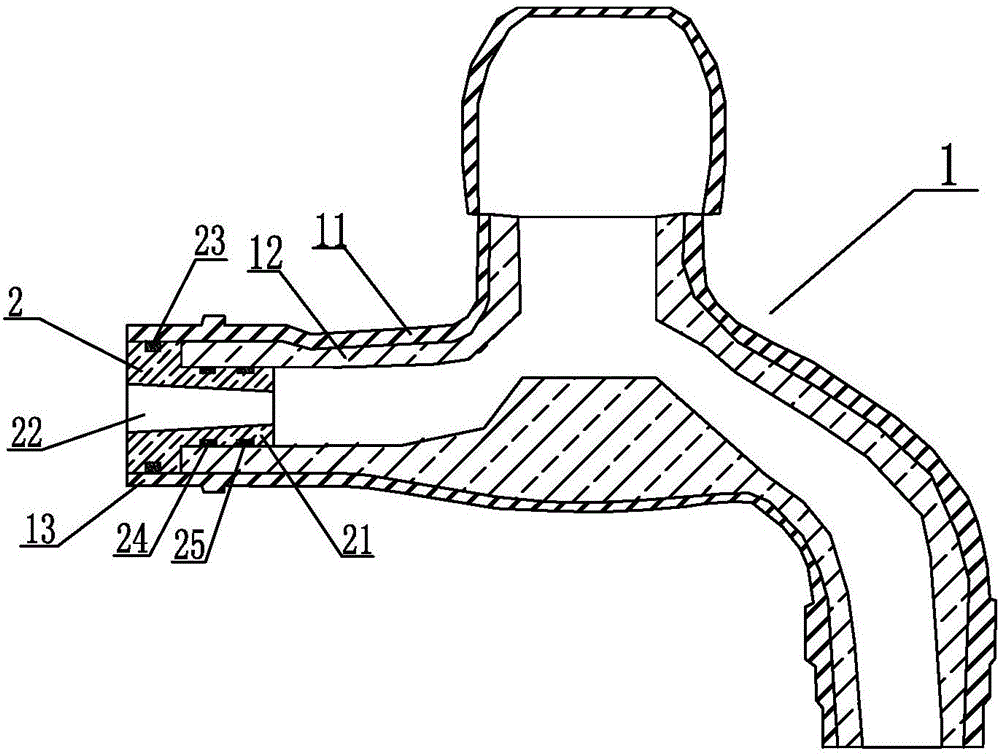

[0016] refer to figure 1 and 2 As shown, a sealing structure of a plastic steel faucet includes a faucet body 1, the faucet body 1 includes a plastic base 12 and a metal shell 11 wrapped on the outer layer of the plastic base 12, the valve core is installed on the plastic base, and the valve core is A handle is provided, and the plastic base 12 is provided with a water inlet and a water outlet. The valve core is used to control the conduction or closure of the water inlet and the water outlet. A threaded joint 13 is provided on the metal shell 11 at the water inlet. In an example, the threaded joint 13 extends outward to expose a part corresponding to the plastic base, and the threaded joint 13 is provided with a sealing plug 2, and the sealing plug 2 is a cylindrical structure. Specifically, the outer peripheral wall of the sealing plug 2 Close to the inner wall of the exposed part of the threaded joint 13, one end of the sealing plug 2 is in close contact with the end face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com