Valve mechanism for stevia confectionery powder processing

A valve and candy technology, applied in the valve shell structure, lift valve, valve details, etc., can solve the problems of low drying efficiency, low discharge efficiency, easy to stay in, and achieve large discharge area and high discharge efficiency. , open the effect of high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

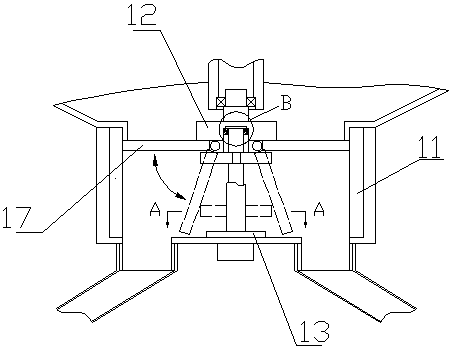

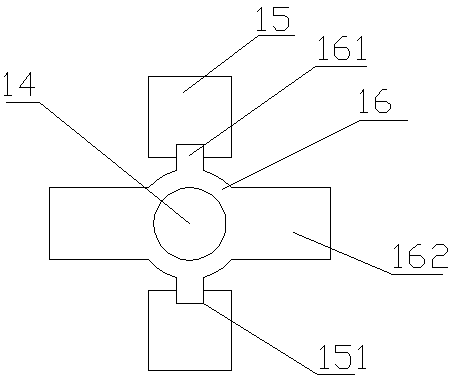

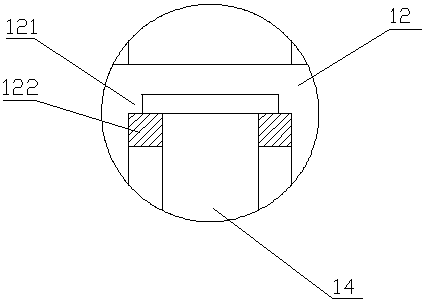

[0014] Such as figure 1 and figure 2 As shown, the valve mechanism used for stevia candy powder processing in this embodiment is installed at the discharge port at the bottom of the drying box. The valve mechanism includes a housing 11, an upper seat plate 12, a lower seat plate 13, a screw rod 14, a bracket 15, and a nut 16 and two opposite semicircular valves 17, the housing 11 is connected to the bottom of the drying box, the upper seat plate 12 and the lower seat plate 13 are respectively arranged at the upper end and the lower end of the inner cavity of the housing 11, and the screw rod 14 is vertically arranged on the shell The center position of the inner cavity of the body 11, and the upper and lower ends are respectively rotatably connected to the upper seat plate 12 and the lower seat plate 13, and the two valves 17 are respectively arranged on both sides of the screw rod 14 and symmetrically hinged on the bottom of the upper seat plate 12. Protrusions 161 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com