Parallelism checking device for spinning carding machine cylinder four-corner positioning detector

A calibration device and parallelism technology, applied in the direction of angle/taper measurement, etc., can solve the problems of inability to detect or calibrate, increase the parallelism error, and affect the quality of the equipment flat car, so as to ensure the operation quality of the equipment, the structure is simple, the Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

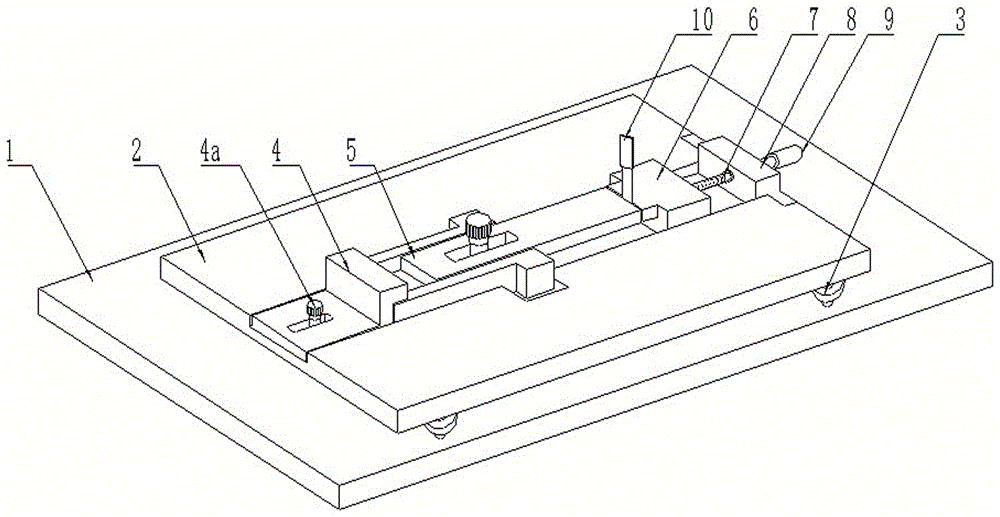

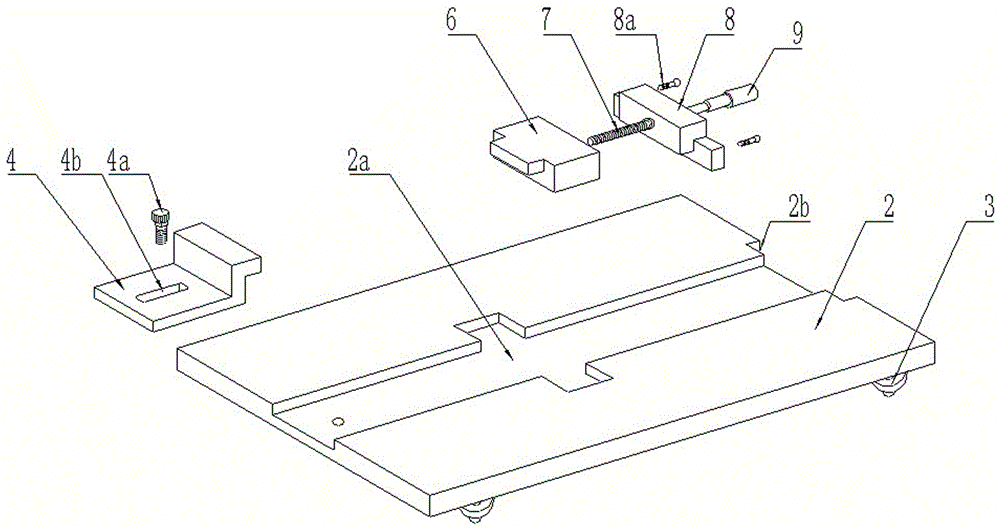

[0012] Below in conjunction with accompanying drawing, the present invention will be further described:

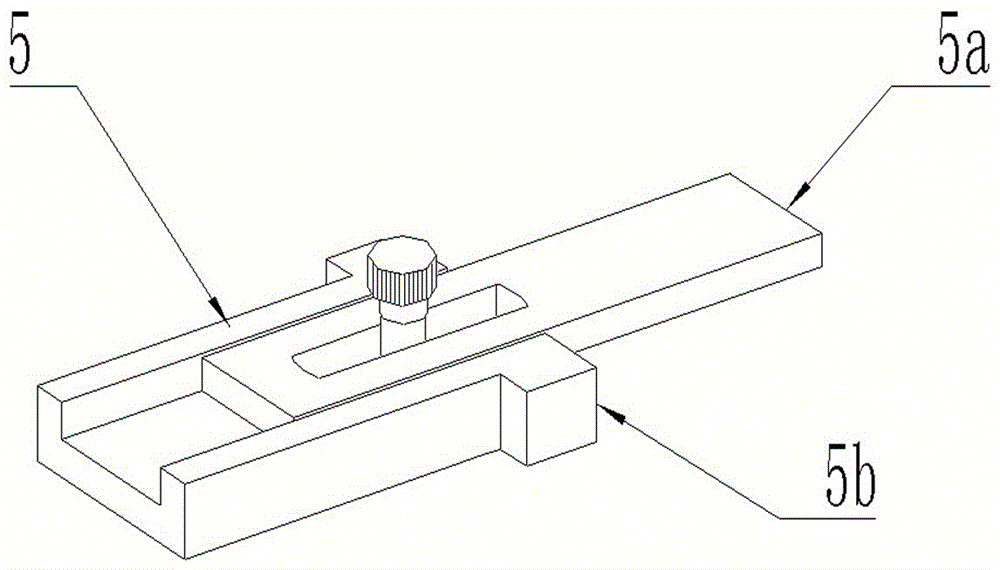

[0013] Such as figure 1 , figure 2 , image 3 As shown, a device for checking the parallelism of the four corners of the cylinder of a textile carding machine in the present invention includes a base 1 on which a detection plate 2 is arranged, and a detection plate 2 is arranged between the base 1 and the detection plate 2. There are a number of leveling feet 3; a "+"-shaped limiting groove 2a is arranged on the top of the detection plate 2, and a clamping piece 4 is arranged at one longitudinal end of the "+"-shaped limiting groove 2a, and the clamping piece 4 Set the thumb screw 4a in the "+"-shaped limiting groove 2a; the other end of the "+"-shaped limiting groove 2a in the longitudinal direction is provided with a groove 2b, and a screw rod is set in the groove 2b through several positioning screws 8a Nut 8; the screw nut 8 is provided with a screw 7, and the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com