Device and method for laser interferometry of inner cone angle

A technology of laser interference and measurement device, applied in the field of laser measurement, can solve the problems of easily damaged cone surface, poor universality of measurement ball, difficult measurement, etc., and achieves the effect of meeting measurement requirements and reducing measurement man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

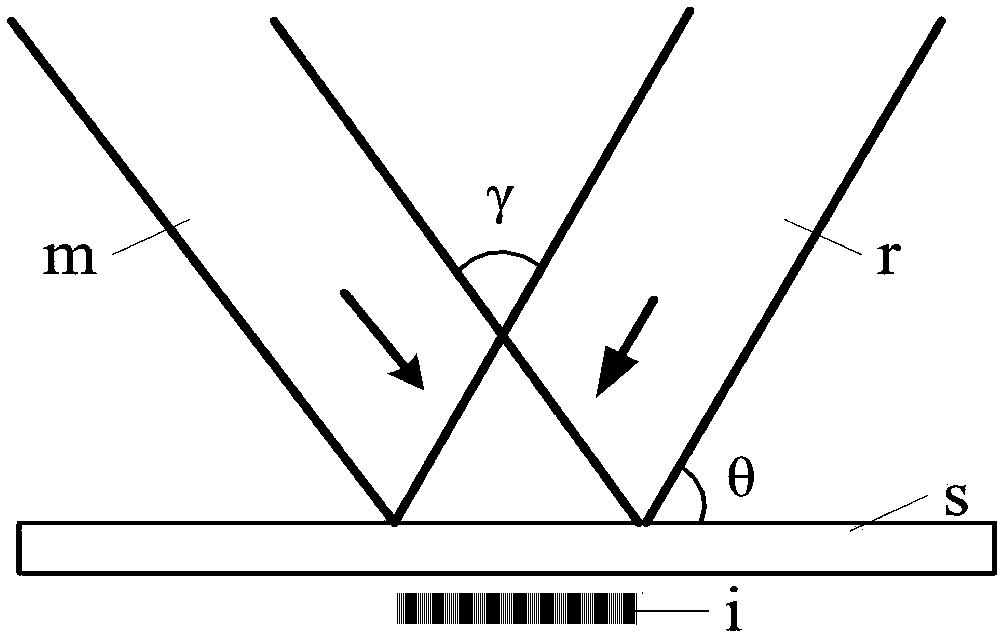

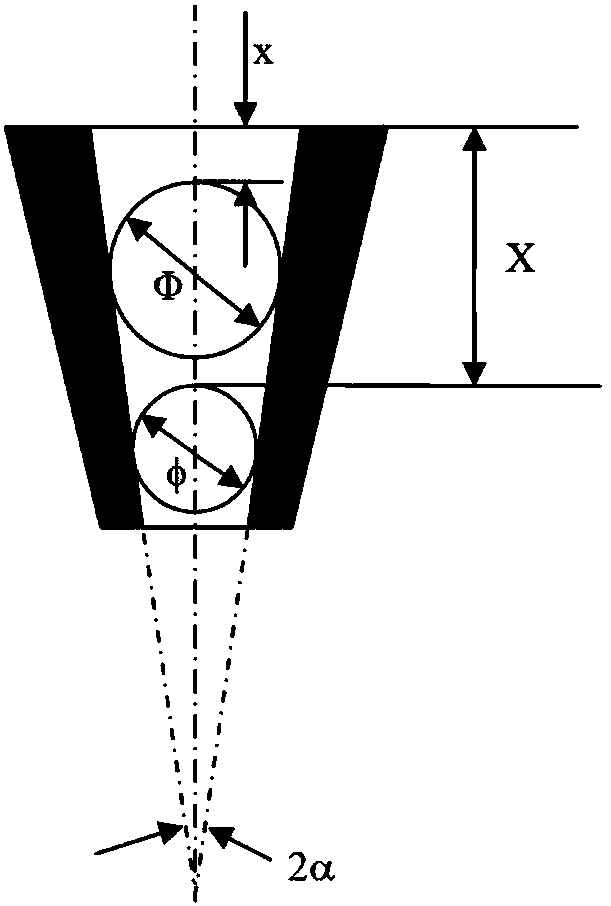

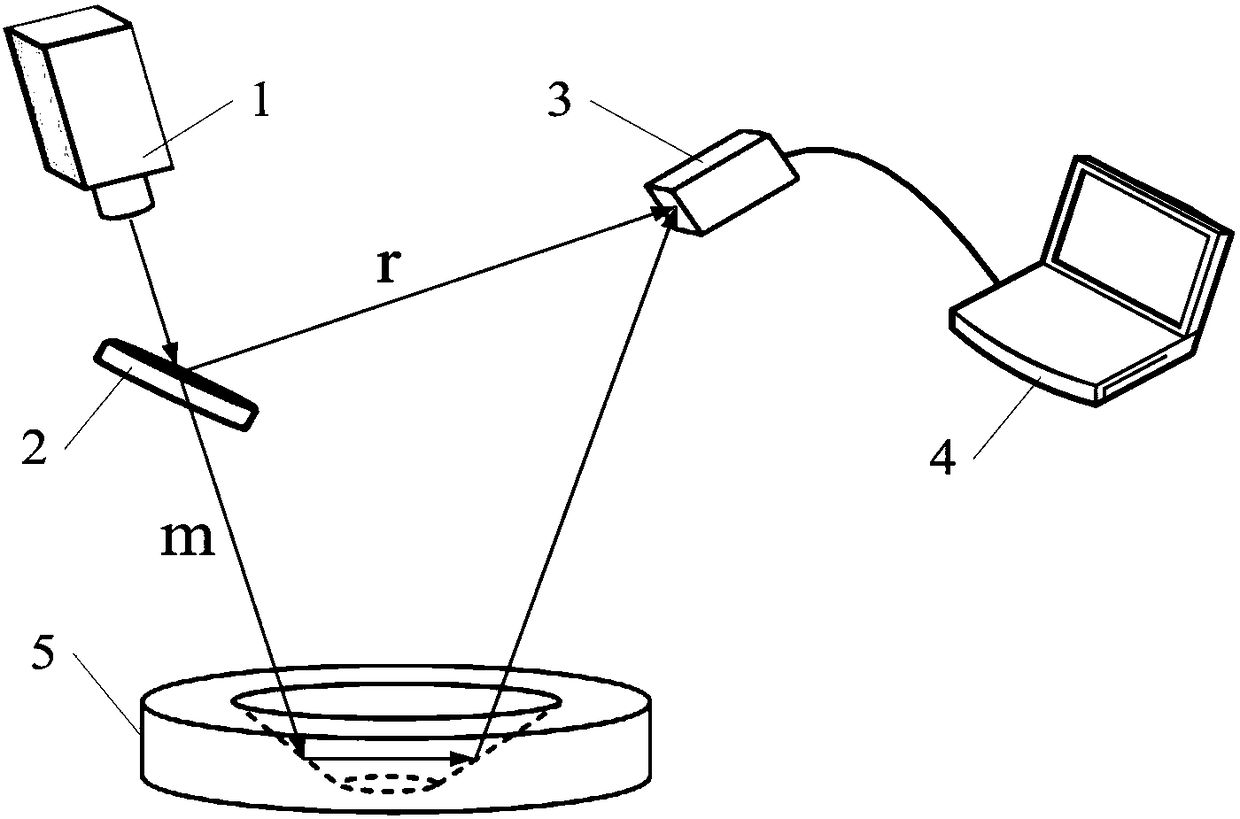

[0012] In the laser interferometry device of the inner cone angle of the present invention, such as figure 2 As shown, the laser 1 and the beam splitter 2 are arranged on the same optical axis, and the angle between the beam splitter 2 and the optical axis is 45°. The output wavelength λ of laser 1 is 532nm. The incident reflection mirror surface of the beam splitter 2 is coated with a film system whose transmittance of the output wavelength λ of the laser 1 is 50%, and the transmission mirror surface of the beam splitter 2 is coated with a film system whose transmittance of the output wavelength λ of the laser 1 is greater than 99.5%. The microscope CCD 3 is located on the reflection optical axis of the beam splitter 2, and the microscope CCD 3 is connected to the computer 4. The included angle θ between the reflected optical axis of the beam splitter 2 and the photosensitive surface s of the microscope CCD 3 is set to 76.98°. At this time, the maximum measurement range of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com