Flexible fingertip pressure sensor and manufacturing method thereof

A technology of a pressure sensor and a manufacturing method, which is applied in the field of force sensors, can solve the problems of low wearing comfort of the elastic body, damage to the body of measuring elements such as capacitance, and small deformation of the elastic body, and achieves simple manufacturing methods, high flexibility, Anti-fatigue improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

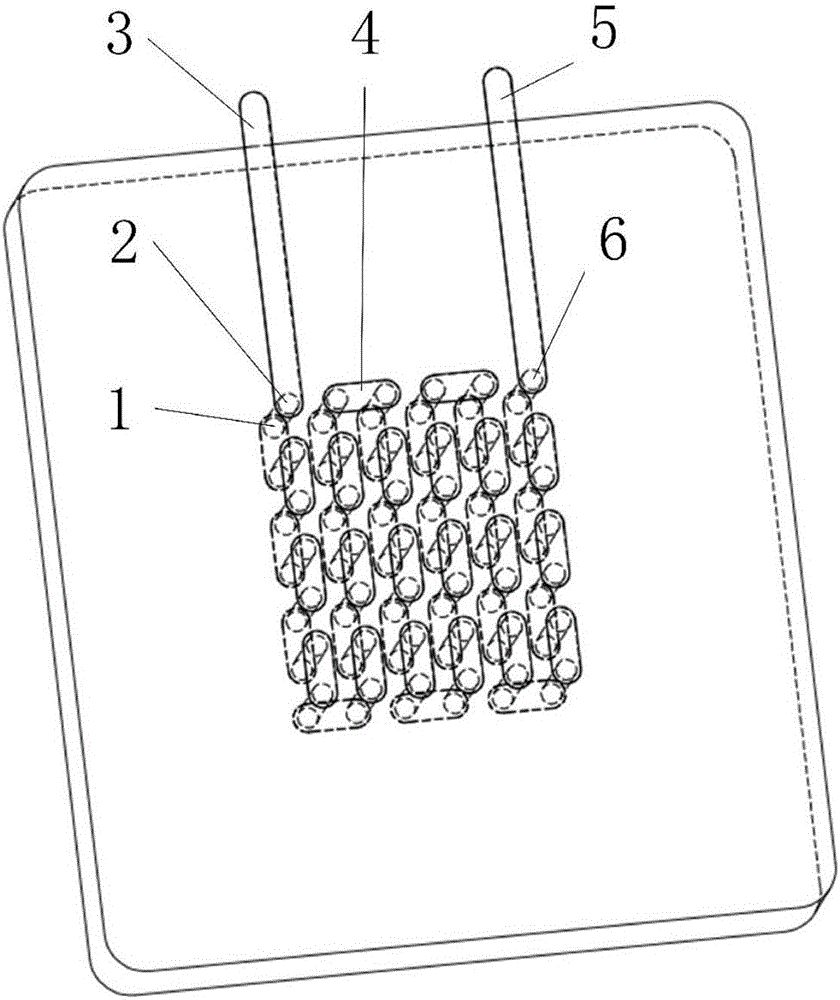

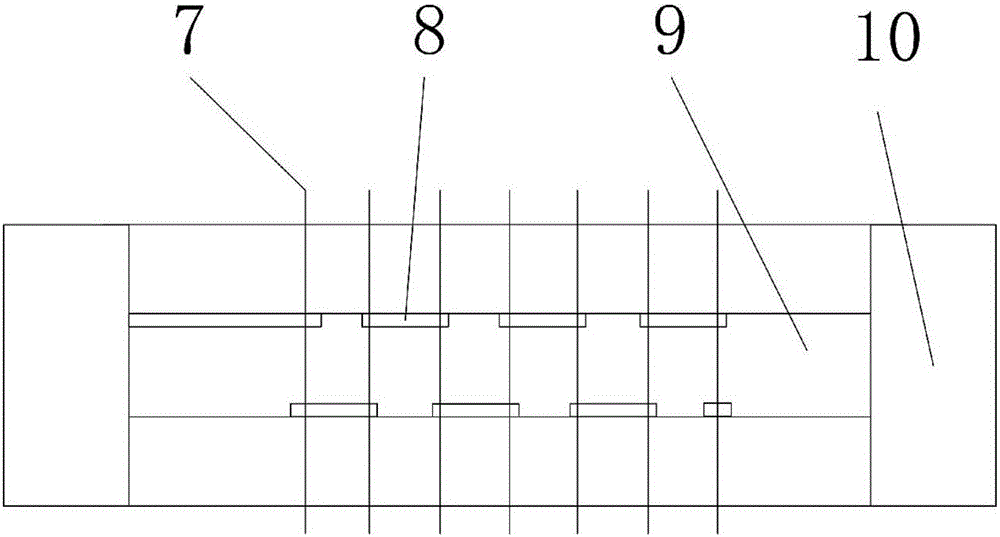

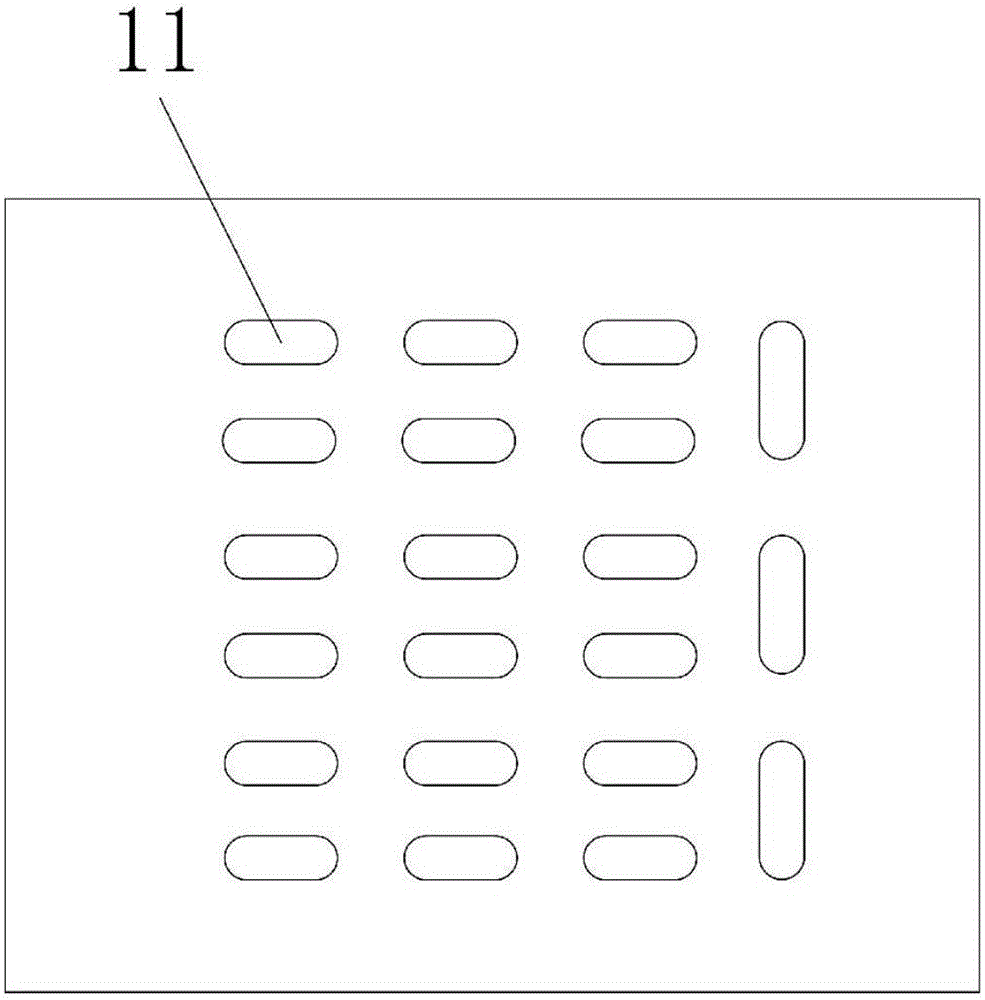

[0039] exist figure 1In the schematic diagram of the present invention shown, the main body of the sensor is an intermediate elastomer made of human body silica gel with a viscosity of 6000CS, the vulcanization time is 12h-24h, and the hardness after vulcanization is 10HS. There are several cylindrical holes 1 inside the sensor body, and 42 cylindrical holes 1 are arranged inside the sensor body. The diameter of the cylindrical holes is 0.2 mm, the length is 3 mm, and the distance between rows and columns is 0.5 mm. All cylindrical holes are provided with a liquid conductive metal gallium indium tin alloy solution inside. The cylindrical holes are regularly arranged in an array, and the cylindrical holes are regularly arranged in an array of seven rows and six columns. The cylindrical holes arranged in the first row, except for the first and last cylindrical holes, the other two adjacent The two cylindrical holes are connected by a metal sheet 4 . The cylindrical holes arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com