Detection method of blanking tube for quartz glass ingot melting

A technology of quartz glass ingot and detection method, which is applied in the direction of using liquid/vacuum degree to measure liquid tightness, program control design, and measuring the rate of increase and deceleration of fluid, etc., which can solve the problems of uncontrolled feeding, material blocking, and production Unable to continue and other problems, to achieve the effect of quantification of test results and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

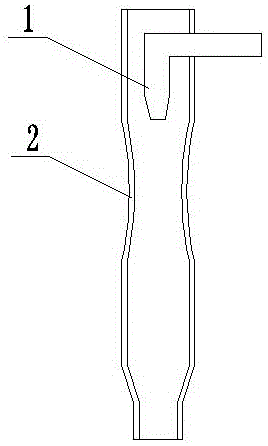

[0020] Determine the medium of the carrier gas and the flow rate of the carrier gas when the quartz glass ingot is actually melted; fix one end of the feeding tube 2 provided with the carrier gas tube 1 on a container with a density of 1.0g / cm 3 In the water container; connect the carrier gas pipe 1 with the carrier gas, and open the flow rate (20.0m³ / h) of the carrier gas to the actual melting of the quartz glass ingot.

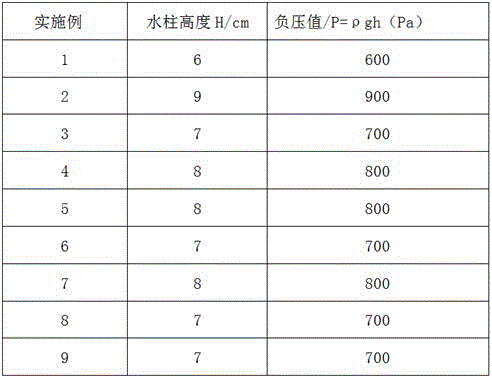

[0021] After the carrier gas is opened, the water column in the feeding pipe 2 will produce liquid level floating under the impact of the carrier gas. At this time, the rise data of the water column is read and recorded with the help of a ruler; the collected water column rise data is substituted into the formula P= ρgh (P negative pressure value; ρ water density, 1000 kg per cubic meter; g acceleration of gravity, 10 N per kg; h water column height value), you can get the range of negative pressure value generated by the carrier gas on the water, the negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com