High Speed Ejection Model Quick Release

A release device and model technology, applied in the field of aerospace engineering, can solve the problems of single launching attitude, short action time, and increased piston movement resistance, etc., and achieve the effects of improving the test success rate, improving the release effect, and increasing the rotational torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0058] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

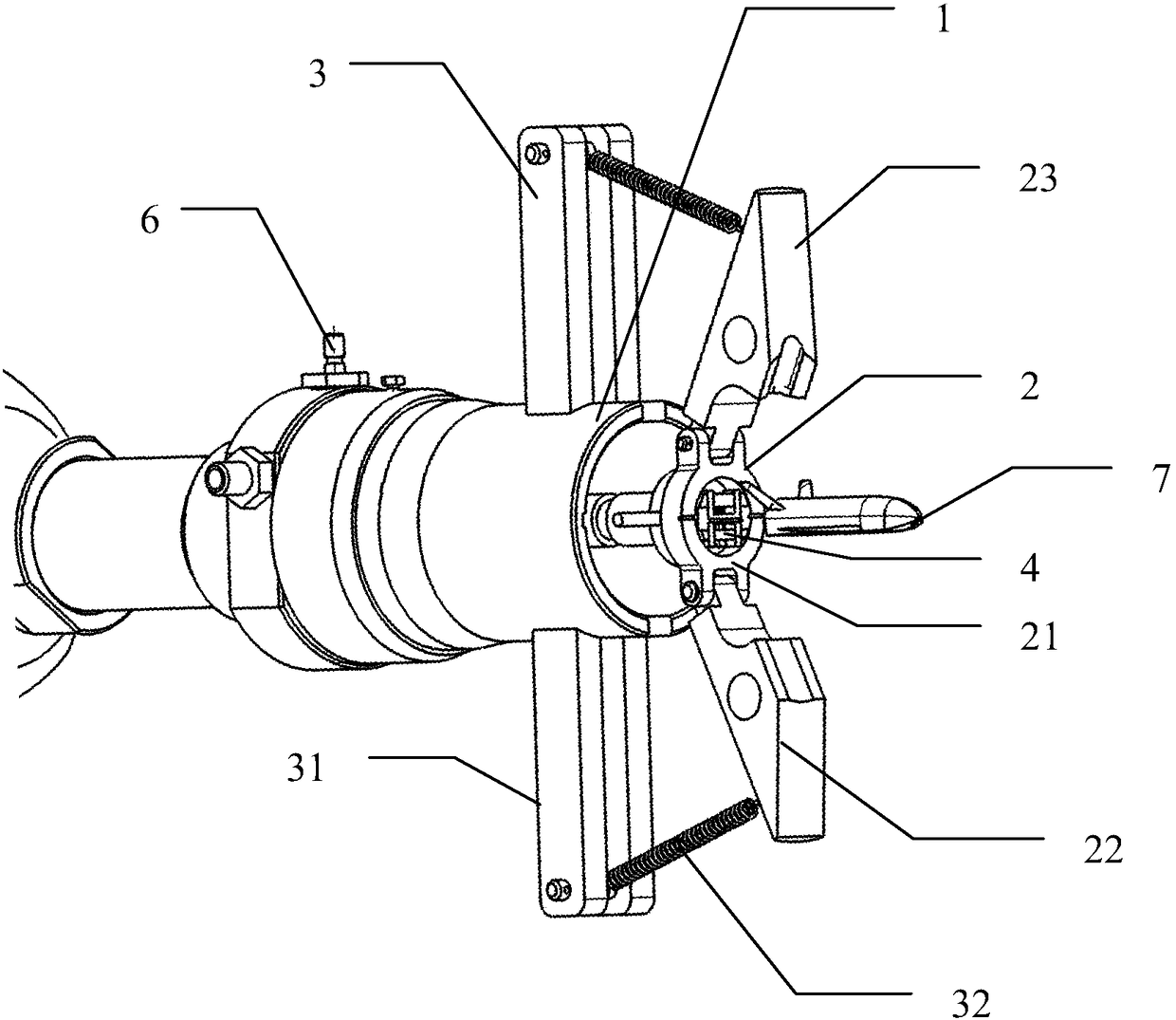

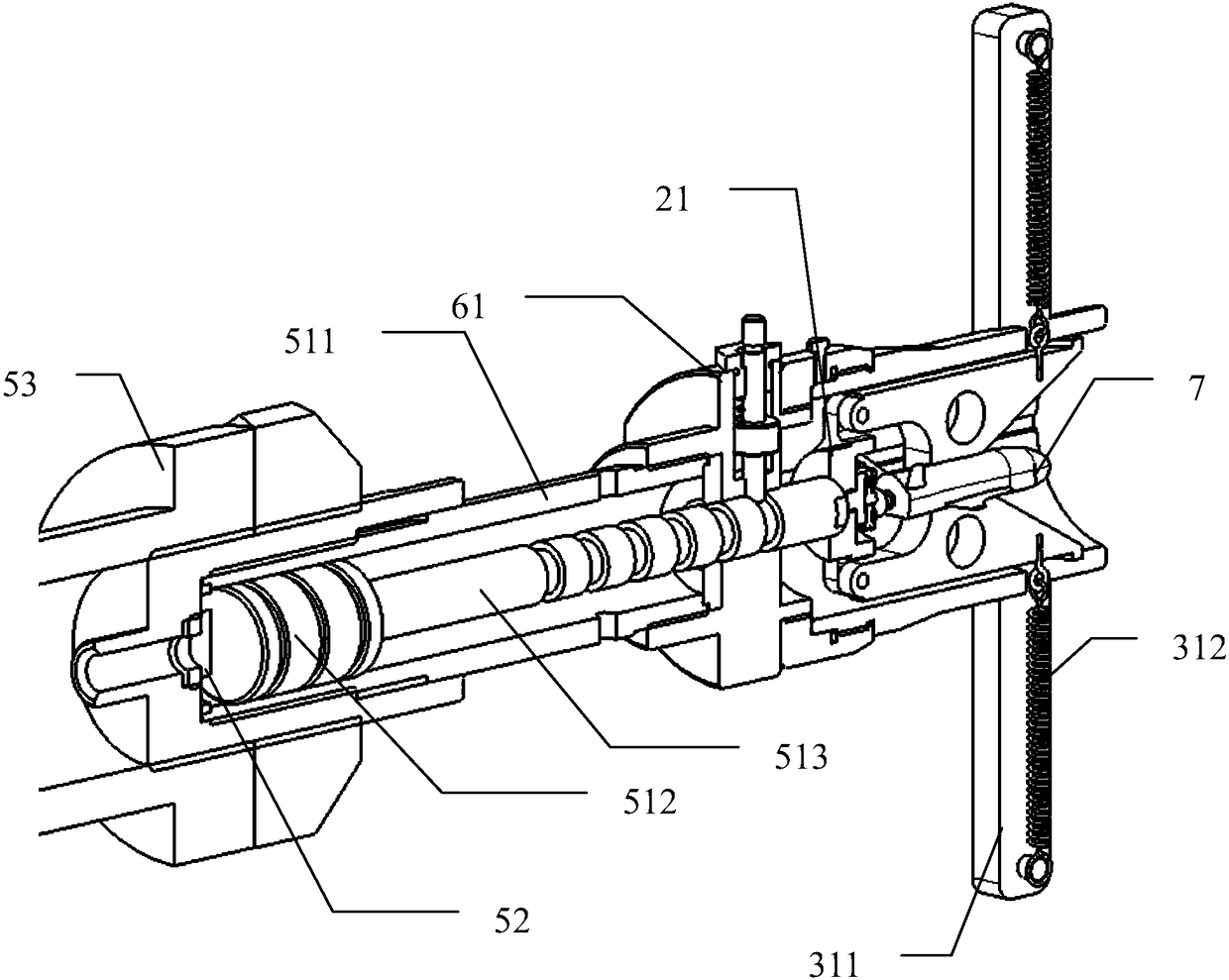

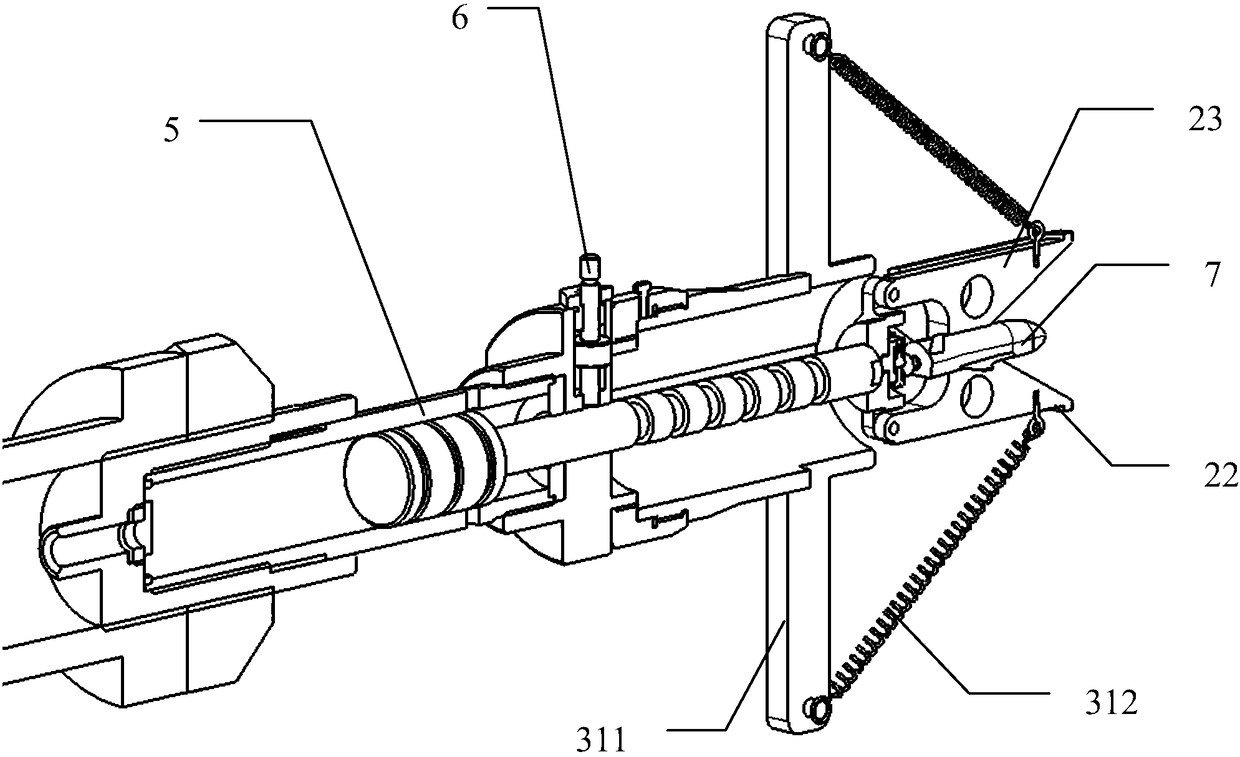

[0059] like Figure 1~4 As shown, the present invention provides a quick release device for a high-speed ejection model, including: a launching cylinder 1 , a launching mechanism 2 , an opening mechanism 3 and a driving mechanism 5 .

[0060] The launch tube 1 is approximately cylindrical and hollow inside. The launch mechanism 2 is movably arranged in the launch tube 1, and the launch mechanism 2 is used to eject the ejection model 7; the launch mechanism 2 includes: a fixed ring 21 and at least two launch claws 22 and 23, taking the launch claw 22 as an example, the launch cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com