Method and device for on-line detection and visual control of alloy composition in casting

An alloy composition and alloy technology, which is applied to the on-line detection and visual control of alloy composition in casting of pre-furnace melt inspection, control, detection of alloy preparation process, and the field of casting alloy ingot and casting molding process, can solve the problem of inconvenience. Provide visual prompts for chemical composition adjustment information, reduce the engineering significance of algorithm models, and can not really effectively guide the casting process production, etc., to achieve the effect of easy guidance of production operations, large market promotion value, and short detection cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment provides detailed implementation methods and specific operating procedures on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments. .

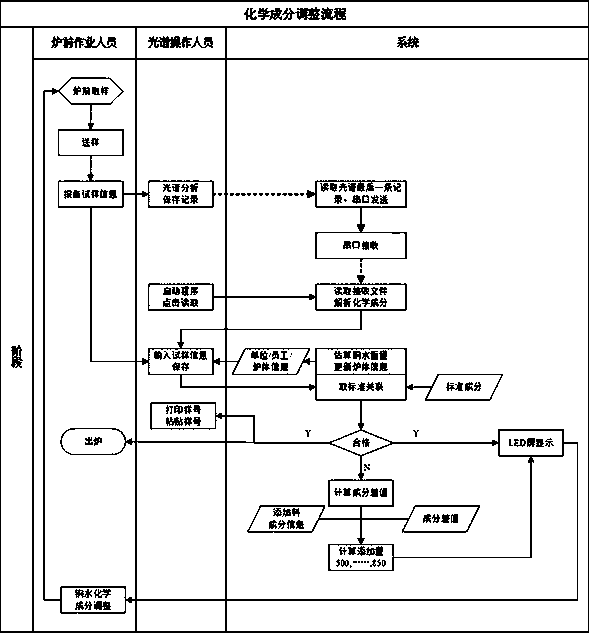

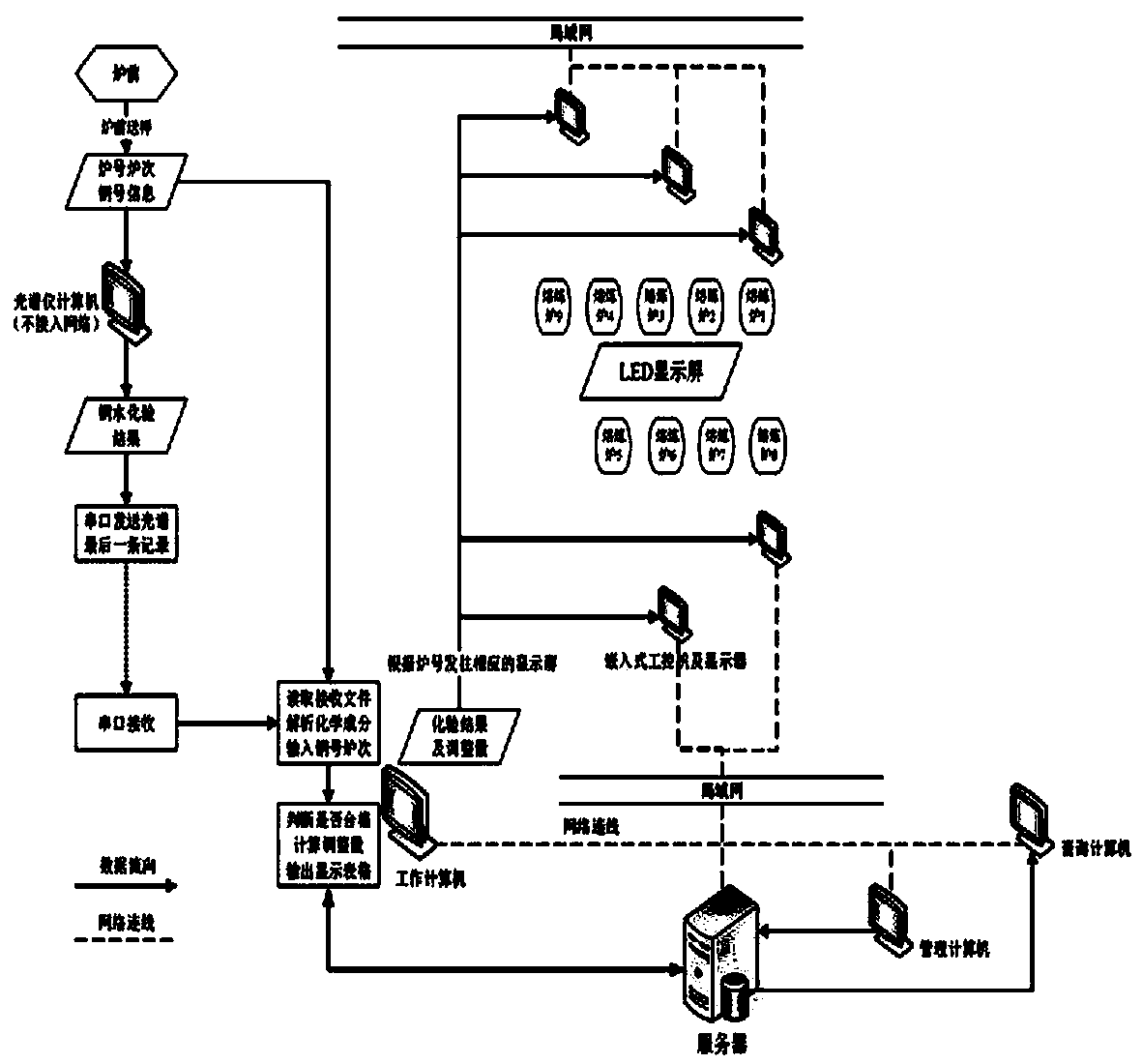

[0027] Such as figure 1 As shown, the method for on-line detection and visual control of alloy composition in casting according to the present invention: the molten steel of the melting furnace is extracted by a sample preparation mold, the chemical composition of the sample is measured by a direct-reading spectrometer, and the visual system of the chemical composition is collected and recorded. The sample chemical composition is compared by the computer calling the casting alloy database to compare the standard chemical composition with the sample chemical composition, calculate the addition amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com