Optical brightness enhancement film and manufacturing method thereof

A brightness-enhancing film and optical technology, which is applied in the field of optics, can solve problems such as light interference and easy scratching of the brightness-enhancing film, and achieve the effects of improving covering performance, facilitating operation, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

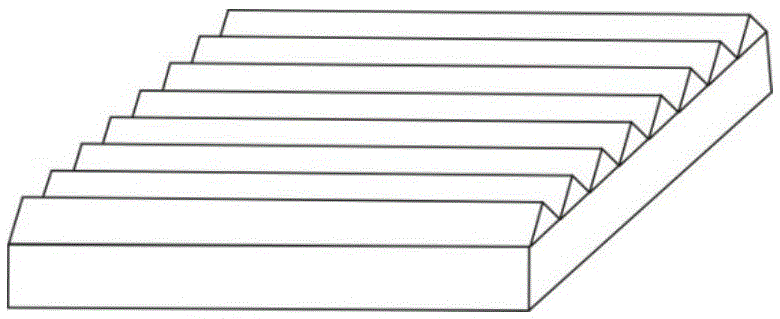

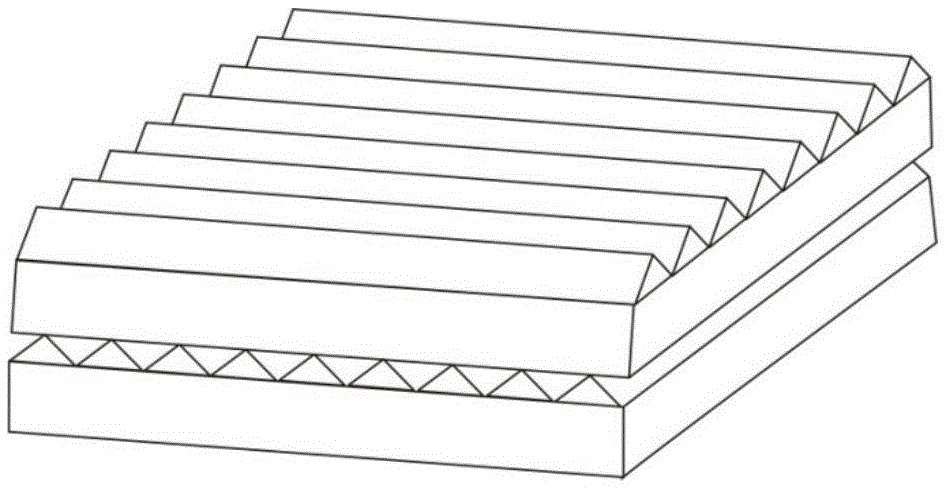

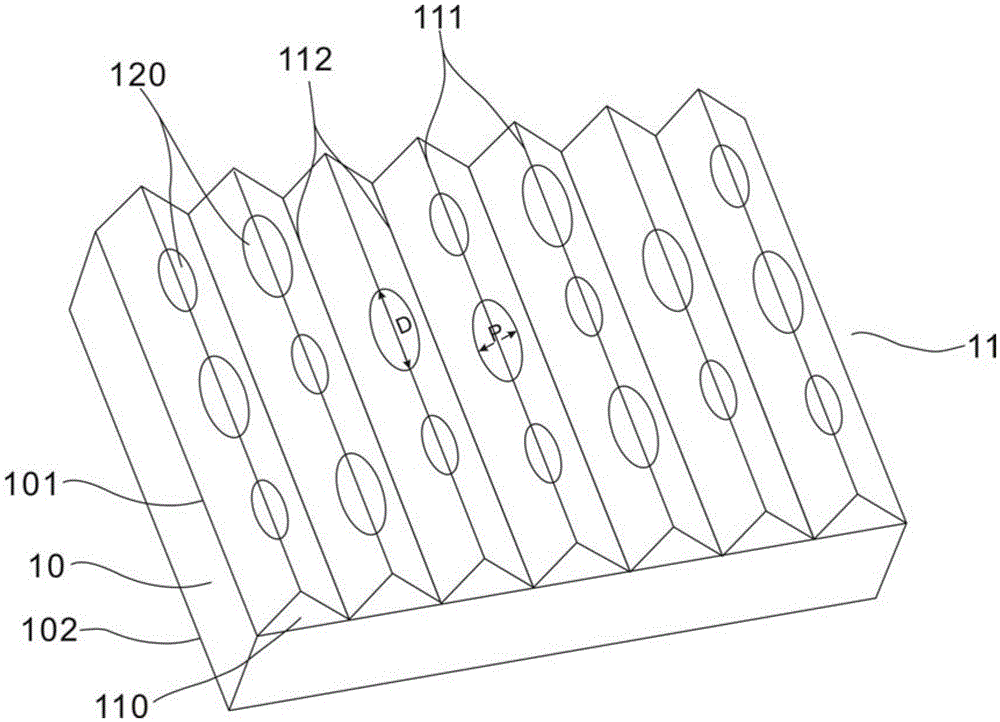

[0065] The present invention provides an optical brightness enhancement film. The brightness enhancement film comprises a substrate layer 10 and a light concentrating microprism structure layer (microprism layer for short) 11, and the light concentrating microprism structure layer 11 is bonded to the substrate. On the surface of the material layer 10, the light concentrating microprism structure layer 11 includes several microprism columns 110;

[0066] The microprism column 110 has a higher peak line 111, and two valley lines 112 positioned on the left and right sides of the peak line 111 and lower in height, and the valley lines 112 of adjacent microprism columns 110 overlap each other; The angle at which the peak line 111 of the microprism column is called the microprism peak angle (also known as the microprism vertex angle);

[0067] An arc-shaped raised structure 120 is arranged on the peak angle of the microprism, and the arc-shaped raised structure 120 is symmetrical ab...

Embodiment 2

[0078] The optical brightness enhancement film provided in Example 1, wherein,

[0079] The material of the substrate layer is polyethylene terephthalate (PET).

[0080] The thickness of the substrate layer 10 is 600 μm.

[0081] The material of the light concentrating microprism structure layer 11 is ultraviolet curable polyurethane acrylate resin.

[0082] The peak angle is 160 degrees; the height H of the microprism column 110 is 50 μm.

[0083] The transverse width of the arc-shaped raised structure 120 is P, 30 μm≤P≤40 μm; the length of the arc-shaped raised structure 120 parallel to the length of the microprism column 110 is the longitudinal length, and the longitudinal length is D, 250 μm≤D≤ 300 μm.

[0084] The height from the peak line 111 of the microprism column 110 to the highest point of the arc-shaped convex structure 120 is H°, 15 μm≤H°≤20 μm.

[0085] The distance between adjacent lowest points of the adjacent arc-shaped convex structures 120 is L, and 4800...

Embodiment 3

[0087] The optical brightness enhancement film provided in Example 1, wherein,

[0088] The material of the substrate layer is polycarbonate (PC).

[0089] The thickness of the substrate layer 10 is 300 μm.

[0090] The material of the light concentrating microprism structure layer 11 is ultraviolet curable polyurethane acrylate resin.

[0091] The peak angle is 100 degrees; the height H of the microprism column 110 is 25 μm.

[0092] The transverse width of the arc-shaped protrusion structure 120 is P, 10 μm≤P≤15 μm; the longitudinal length of the arc-shaped protrusion structure 120 is D, 120 μm≤D≤150 μm.

[0093] The height from the peak line 111 of the microprism column 110 to the highest point of the arc-shaped convex structure 120 is H°, 8 μm≤H°≤10 μm.

[0094] The distance between adjacent lowest points of the adjacent arc-shaped convex structures 120 is L, 2200 μm≤L≤2500 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Horizontal width | aaaaa | aaaaa |

| Longitudinal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com