Mixed assembly sequence generation method based on symbols

A hybrid assembly and sequence generation technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve the problems of complex processing of dead states, reducing the efficiency and scale of solving assembly sequence planning problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

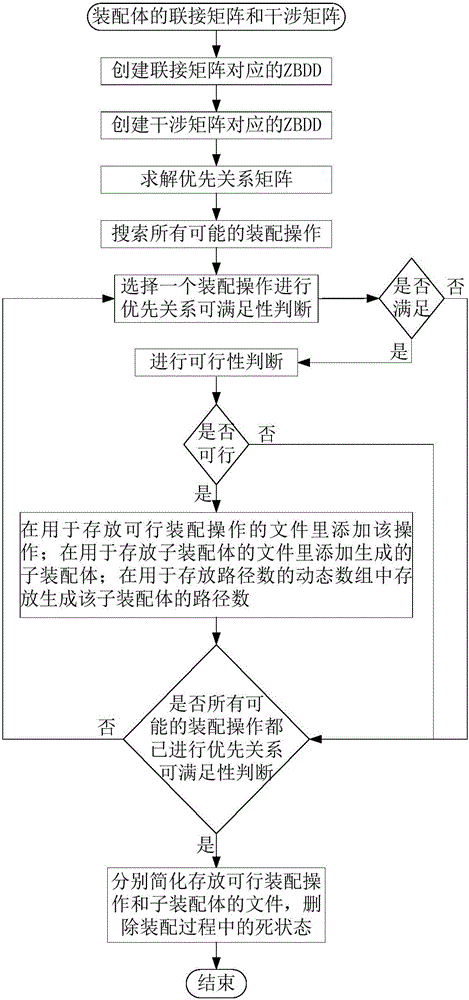

[0073] The invention discloses a method for generating a mixed assembly sequence based on symbols, comprising the following steps: obtaining assembly knowledge, that is, a connection matrix and an interference matrix of the assembly; creating a ZBDD representation of the connection matrix according to the connection matrix of the assembly; According to the interference matrix of the body, create the ZBDD representation of the interference matrix; solve the priority relationship matrix according to the interference matrix of the assembly; search for all feasible assemblies, that is, the feasible assembly sequence, and create a file to store the feasible assembly sequence and the child generated during the assembly process Assemblies, create a dynamic array to store the number of paths to generate each sub-assembly; refine the generated files storing feasible assembly sequences and sub-assemblies, and delete the dead state during the assembly process. The present invention can en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com