Improved beverage bottle recovering machine and beverage bottle recovering method thereof

A technology for recycling machines and beverage bottles, applied in the direction of starting with returnable containers, coinless or similar appliances, instruments, etc., can solve the problems of limited promotion and high cost, and achieve non-destructive, long service life, and improve environmental protection conscious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

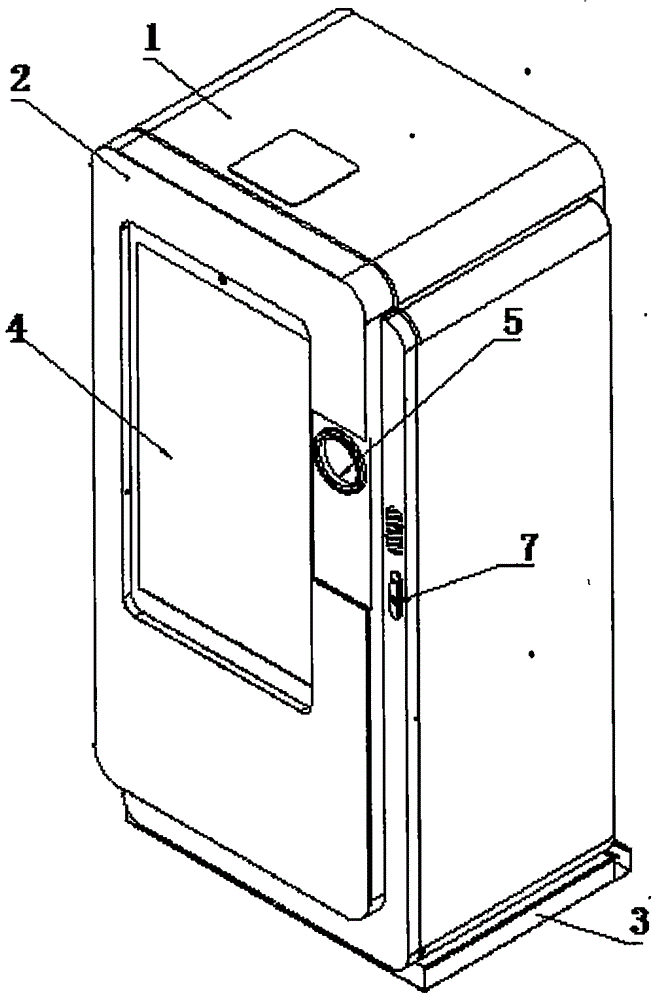

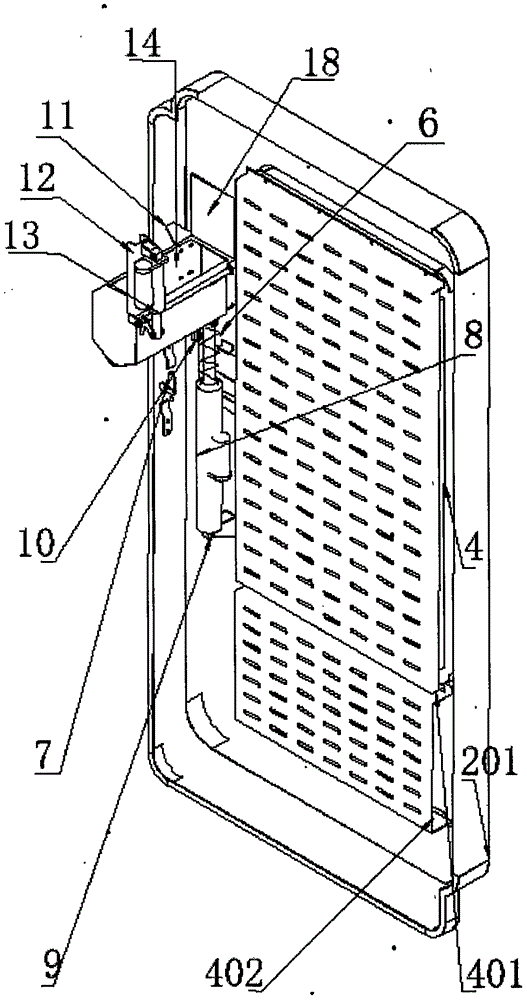

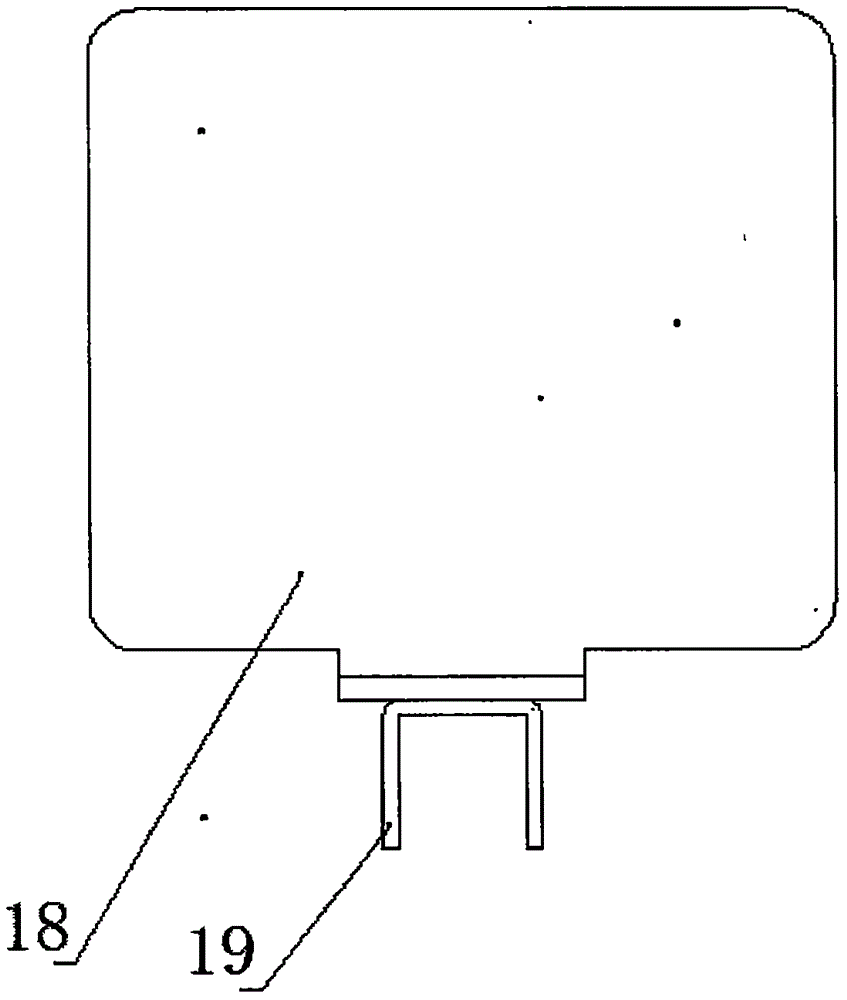

[0020] like figure 1 , figure 2 , image 3 , Figure 4 The improved beverage bottle recycling machine of the present invention shown includes a base 3, a recycling machine main body 1 arranged on the base 3, and a front door assembly 2 is provided outside the recycling machine main body 1, and the front door assembly 2 includes a The front door main body 201 hinged on one side of the main body 1 of the recycling machine, the outer wall of the front door main body 201 is provided with a touch display screen 4 and a feeding port 5, the feeding port 5 is arranged on the other side of the front door main body 201, and the inner wall of the front door main body 201 is provided with a corresponding touch display screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com