Method for producing local concave-convex structure and anti-counterfeiting method

A technology of a concave-convex structure and a production method, which is applied in the field of anti-counterfeiting, can solve the problems of simple production process of the anti-counterfeiting structure, and the anti-counterfeiting structure is easy to be imitated, and achieves the effects of increasing the reliability of anti-counterfeiting, being suitable for mass production, and having a high degree of integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

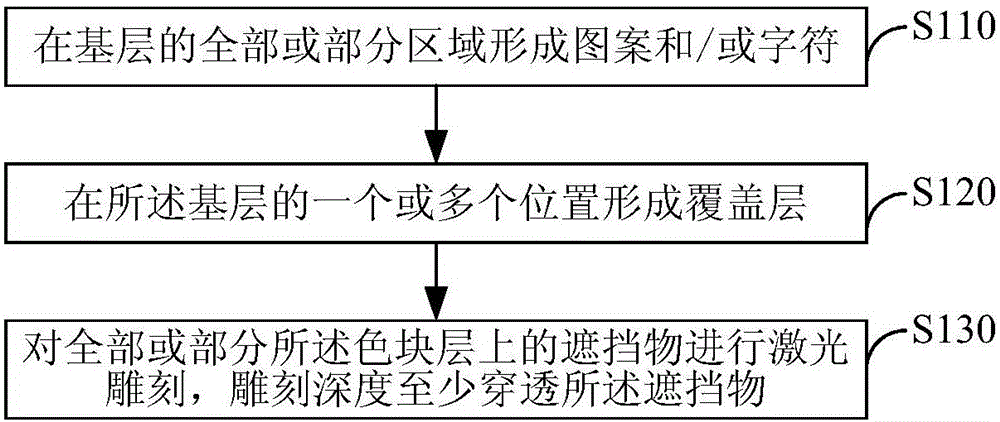

[0039] Embodiment 1, a kind of production method of local concave-convex structure, such as figure 1 shown, including:

[0040] S110, forming patterns and / or characters on all or part of the base layer; the formed patterns and / or characters can be used as anti-counterfeiting information in whole or in part;

[0041] S120. Before or after forming the pattern and / or characters, form a covering layer on one or more positions of the base layer, and each covering layer includes at least one covering sublayer;

[0042] Wherein, the covering sublayer may be a color block layer, and the color block layer includes one or more color blocks attached to the surface of the base layer;

[0043] S130. Perform laser engraving on all or part of the blocking objects on the color block layer, and the engraving depth at least penetrates the blocking objects. Wherein, the blocking object on the color block layer may be the outermost covering sub-layer in the covering layer.

[0044] In this emb...

Embodiment 2

[0057] Embodiment 2. This embodiment describes the process of producing a local concave-convex structure according to the method of Embodiment 1. The covering layer contains at least two covering sublayers, one covering sublayer is a color block layer, and the other covering sublayer is an opaque material layer. Condition.

[0058] In an optional solution of this embodiment, at least one of the covering layers further includes an opaque material layer coated on the color block layer; the opaque material layer forms the shield. That is, the penetrating area is disposed on the opaque material layer.

[0059] Wherein, the opaque material layers of different covering layers may be independent or continuous with each other to form a whole.

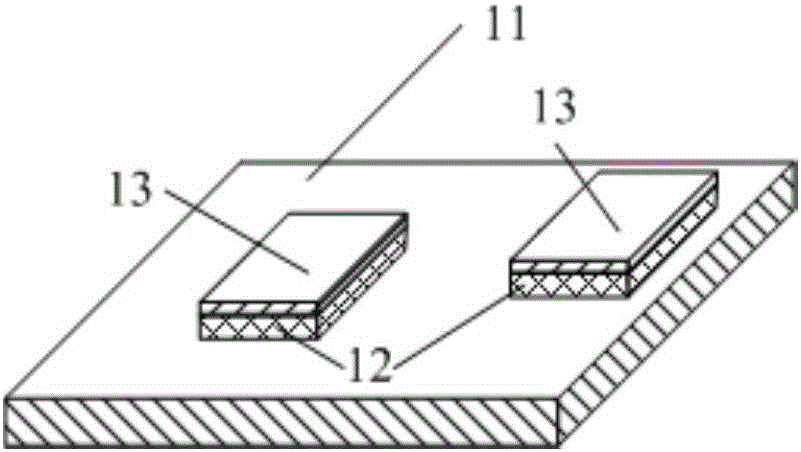

[0060] An example of this implementation is figure 2 As shown, two covering layers are arranged on one surface of the base layer 11, and each covering layer includes two covering sublayers, one covering sublayer is the color block layer 12, ...

Embodiment 4

[0139] Embodiment 4. An anti-counterfeiting method, comprising:

[0140] Collecting image information on the local concave-convex structure produced by the method in any one of embodiments 1 to 3; the image information includes at least the position of part of the covering layer on the base layer and part of the penetration area shape and color;

[0141] When receiving the anti-counterfeiting query information, feedback the corresponding image information.

[0142] In this embodiment, before or after collection, the local concave-convex structure can also be attached to the product or its packaging; the attachment method can be but not limited to pasting, or it can be compounded by using a composite machine to combine the material on the product. on the film packaging. If the image information is first attached and then collected, and the depth of all or part of the penetrating area is such that the penetrating area runs through the entire local concave-convex structure, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com