Rotary sealed brushless direct-current motor

A brushed DC motor, rotary technology, applied in the field of brushless DC motors, can solve problems such as printed circuit board deformation, Hall component failure, etc., to achieve the effect of preventing failure, realizing adjustment, and ensuring coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

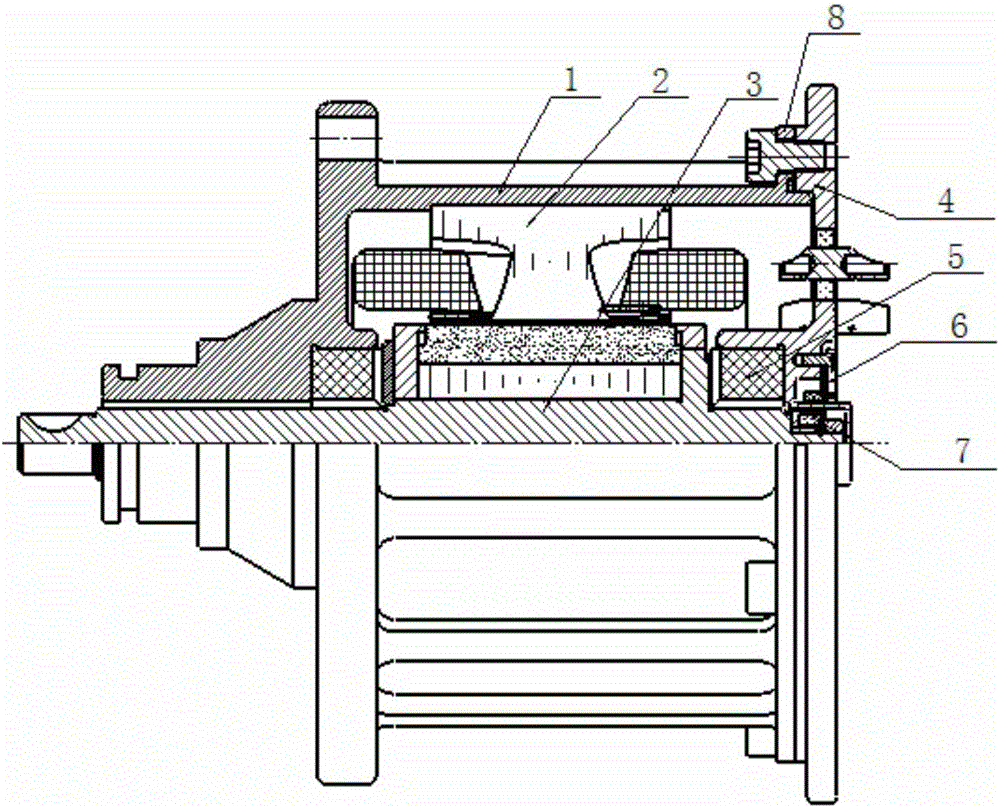

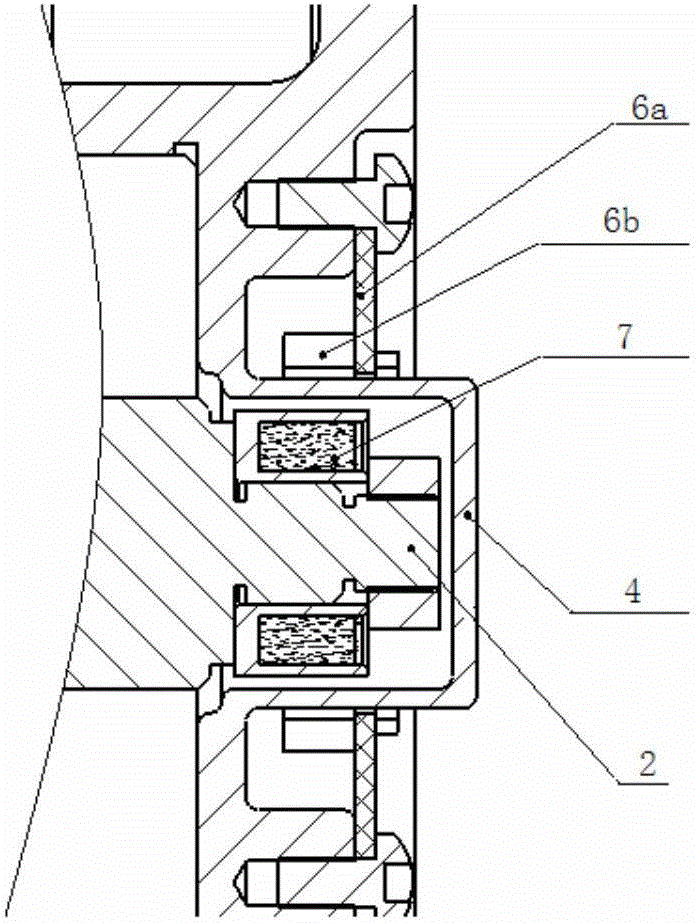

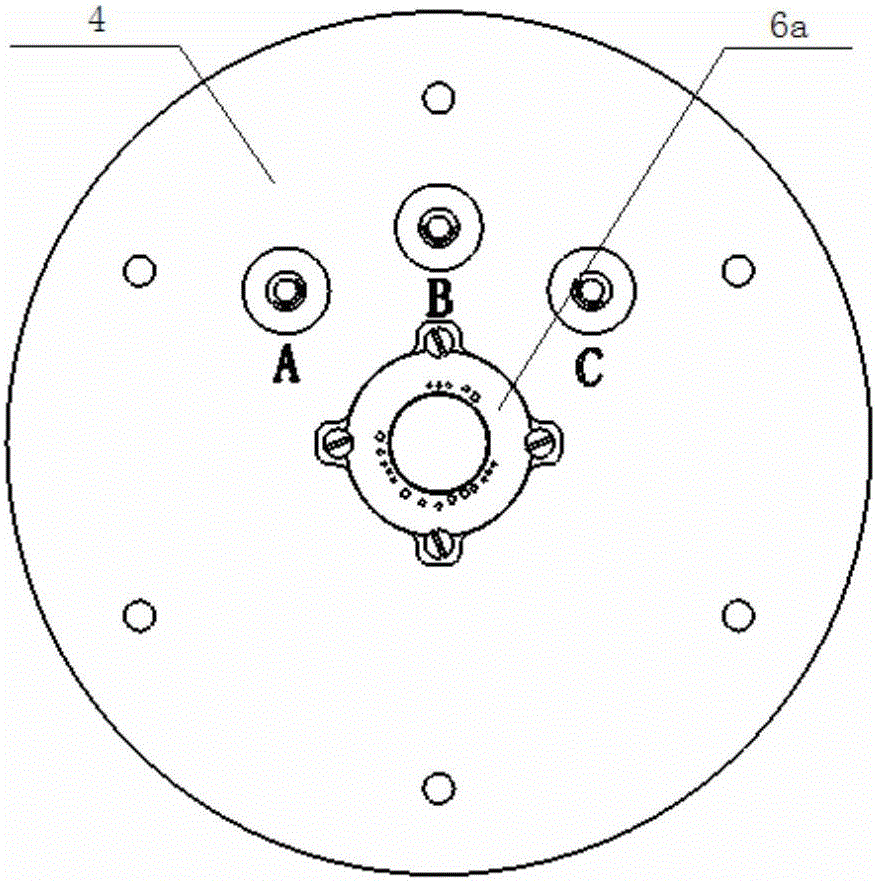

[0017] A rotary sealed brushless DC motor such as figure 1 , 2 As shown, it includes: including: housing 1, stator 2, rotor 3, rear cover assembly 4, bearing 5, circuit board assembly 6, sensor rotor 7, sealing ring 8; rear cover assembly 4 is connected to the tail of housing 1 and passed through The sealing ring 8 forms a sealing structure, the stator 2 is installed inside the housing 1, the rotor 3 is installed on the housing 1 and the rear cover assembly 4 through the bearing 5, the sensor rotor 7 is fixed at the tail of the rotor 3, and the circuit board assembly 6 is installed on the rear cover Outside the assembly 4; the circuit board assembly 6 includes a circuit board 6a and a Hall element 6b, the Hall element 6b is welded on the circuit board 6a, and the internal corrosion of the circuit board 6a, Hall element 6b and the motor is realized th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com