Miscellaneous grain tempeh product and production method thereof

A technology of miscellaneous grains and products, applied in the field of miscellaneous grains and tempeh and its production, can solve the problems of unbalanced and single nutrition, and achieve the effects of short fermentation time, good quality and rich varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

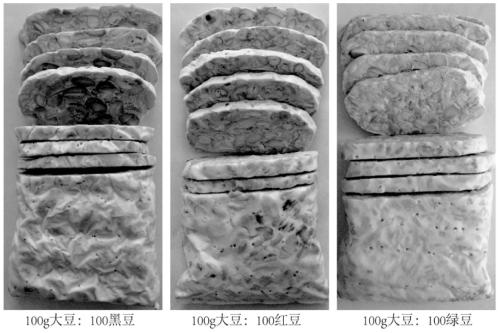

[0039] The tempeh product comparison that embodiment 1 different kinds miscellaneous beans make

[0040] Preparation:

[0041] Soak and cook beans to measure the weight, add 100g of black beans, red beans and mung beans to 100g of soybeans, add 8g of starch, 12ml of white vinegar, add LT0229 spore suspension, about 10 5 ~10 7 spores / mL culture medium, the inoculum amount was 1%, stirred evenly, put into No. 5 plastic bag, pierced, cultured at 32°C for 36h, and observed the quality of miscellaneous grains and tempeh products.

[0042] Result evaluation: see Table 1

[0043] Table 1 Sensory evaluation of miscellaneous grain tempeh obtained from different beans

[0044]

[0045] Add 100 g of black beans, red beans, and mung beans to 100 g of soybeans, and culture them at 32°C for 36 hours. The surface and interior of the fermented products are covered with mycelia. figure 1 );

[0046] The flavors of fermented products obtained by adding different beans are different.

...

Embodiment 2

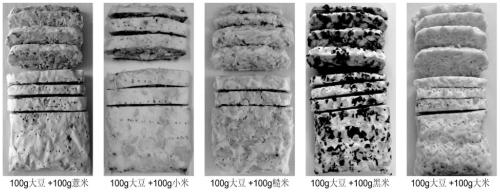

[0049] Embodiment 2 Comparison of tempeh products made from different types of miscellaneous grains

[0050] Preparation:

[0051] Measure the weight of soaked and cooked beans, add 100g each of soaked barley, millet, black rice, brown rice and rice to 100g of soybeans; because rice is a carbon source, you can choose to add starch or not; white vinegar 12ml, add LT0229 Spore suspension, about 10 5 ~10 7 spores / mL culture medium, the inoculum amount was 1%, stirred evenly, put into No. 5 plastic bag, pierced holes, and cultivated at 32°C until the hyphae were evenly distributed on the surface of the miscellaneous grain tempeh, and the sensory analysis was carried out.

[0052] Result evaluation: see Table 2 and figure 2 .

[0053] Table 2 Sensory evaluation of miscellaneous grain tempeh obtained from soybean and different types of rice

[0054]

[0055] Add 100g of black rice and rice to 100g of soybeans, and incubate at 32°C for 36 hours. The surface and interior of t...

Embodiment 3

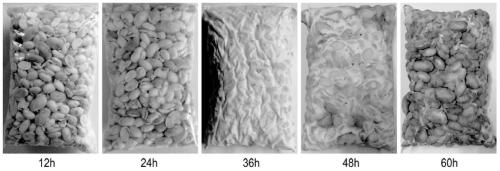

[0061] Example 3 Study on Fermentation Time of Soybean + Black Bean Miscellaneous Grain Tempeh

[0062] method:

[0063] Use soybeans and black beans as the main raw materials, soak and cook 100g of soybeans, 100g of black beans, add 8g of starch, 12ml of white vinegar, add LT0229 spore suspension, about 10 5 ~10 7 spores / mL culture medium, the inoculum amount was 1%, stirred evenly, put into No. 5 plastic bag, pierced holes, cultured at 32°C for different time to stop fermentation, and observed and recorded the morphology of tempeh.

[0064] Results: See Table 3

[0065] Table 3 Sensory evaluation of miscellaneous grain tempeh obtained at different fermentation times

[0066]

[0067] After fermenting miscellaneous grains and tempeh for 28 hours, a small amount of mycelia can be seen on the surface, but due to the lack of mycelia, the product has poor elasticity, and the cross section is loose and not smooth; if the culture is continued for 32 hours, the growth of mycel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com