Novel hair straightener

A straight plate clamp, a new type of technology, applied in the field of straight plate clamps, can solve the problems of poor temperature control, easy to burn hair, slow heat dissipation, etc., and achieve the effects of reducing damage, fast temperature recovery, and reducing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

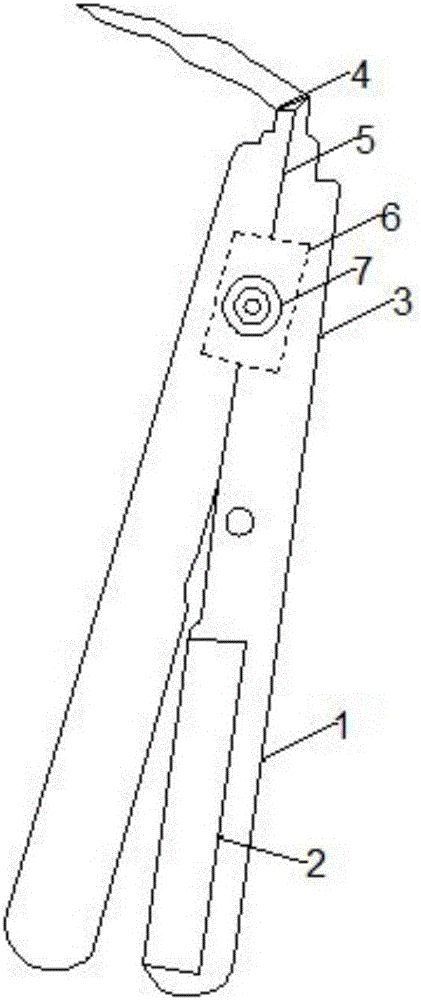

[0019] see figure 1 , the present invention provides a technical solution: a new type of straight clamp, including a straight clamp main body 3, one end of the straight clamp main body 3 is connected to a power cord 4, and the other end is connected to two heating plates 5, and the two heating plates 5 is V-shaped, characterized in that a layer of NST coating 2 is provided on the heating plate 1 to help lock the moisture in the hair, the NST coating 2 is composed of nano-scale particles, and the heating plate 4 passes through The adjustable current circuit 5 is connected to the power line 4, and the adjustable current circuit 5 is installed in the main body 3 of the bar clamp, and the adjustable current circuit 5 controls the current through the rheostat 6, and the adjusting knob 7 on the rheostat 6 is externally connected to the bar The surface of the clamp body 1; the NST coating 2 is a Teflon high-temperature adhesive layer; the thickness of the NST coating 2 is 50-80 micro...

Embodiment 2

[0022] The difference from Example 1 is that the same NST coating 2 is used and placed on the curlers to help lock the moisture in the hair and minimize the evaporation of moisture in the hair during the hair pulling process.

[0023] The heating plate equipped with NST coating of the present invention can help to lock the moisture in the hair and minimize the volatilization of hair moisture during the hair pulling process; it can effectively reduce the damage to the hair scale layer during the hair pulling process and smooth the hair surface. Debris; due to the characteristics of NST coating, the sharp peaks on the hair surface can become smoother after pulling, so the hair will be smoother and shiny after pulling; the surface of NST coating is very smooth, and it will not pull when pulling Hair; the heating plate with NST coating can effectively save the temperature, and the temperature recovery speed is very fast, and it provides a uniform and gentle temperature, which great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com