Roller device for waste biochemical treatment, biochemical treatment equipment, biochemical treatment system and biochemical treatment method

A biochemical treatment and roller technology, applied in biochemical treatment systems, biochemical treatment equipment, roller devices, and biochemical treatment fields, can solve the problems of picking up, reducing waste disposal space, and incapable of contacting conical blades, achieving easy operation and cost saving , the effect of simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Biochemical treatment system and biochemical treatment equipment

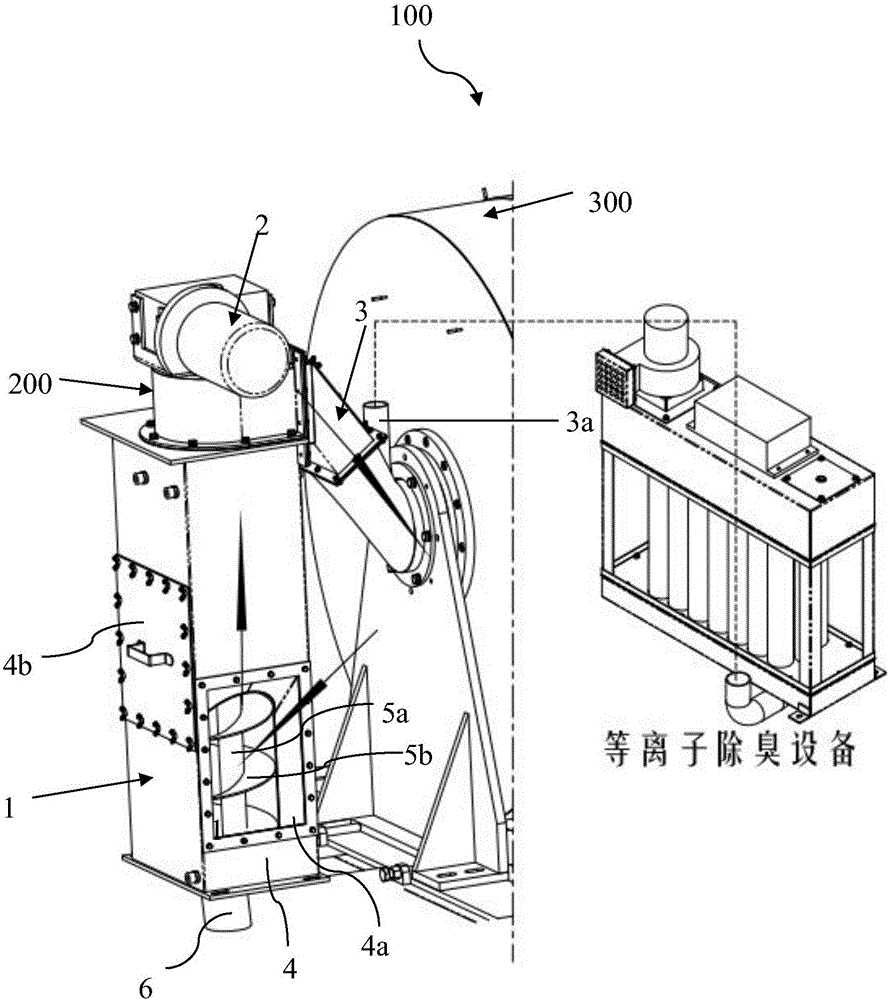

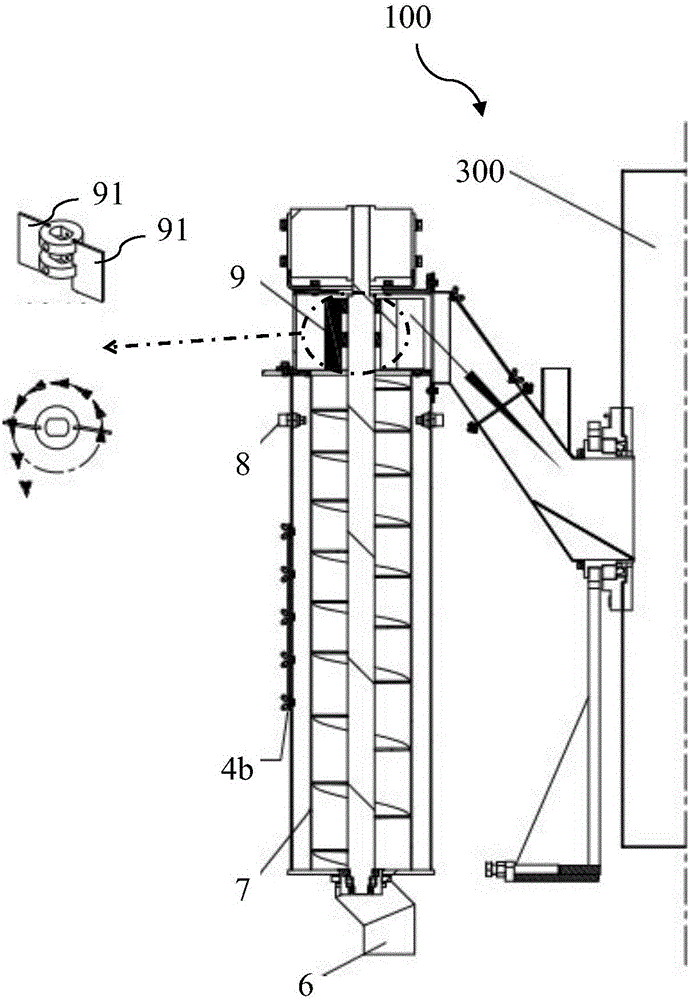

[0040] figure 1 It is a schematic structural diagram of the biochemical treatment system in this embodiment.

[0041] Such as figure 1 As shown, the biochemical treatment system 100 is composed of feeding equipment 200, biochemical treatment equipment 300 and control equipment. The feeding device 200 is used to deliver the organic waste to be treated to the biochemical treatment device 300 , the biochemical treatment device 300 is used to reduce the amount of organic waste, and the control device is used to control the feeding device and the biochemical treatment device.

[0042] The feeding equipment 200 includes a garbage crushing device 1 , a driving device 2 and a crushed material conveying device 3 . The garbage crushing device 1 is vertically arranged, and the top is connected with the driving device 2; the driving device 2 is a geared motor; one end of the crushing material conveying devic...

Embodiment 2

[0120] In the second embodiment, the same structures as those in the first embodiment are assigned the same symbols, and the same descriptions are omitted.

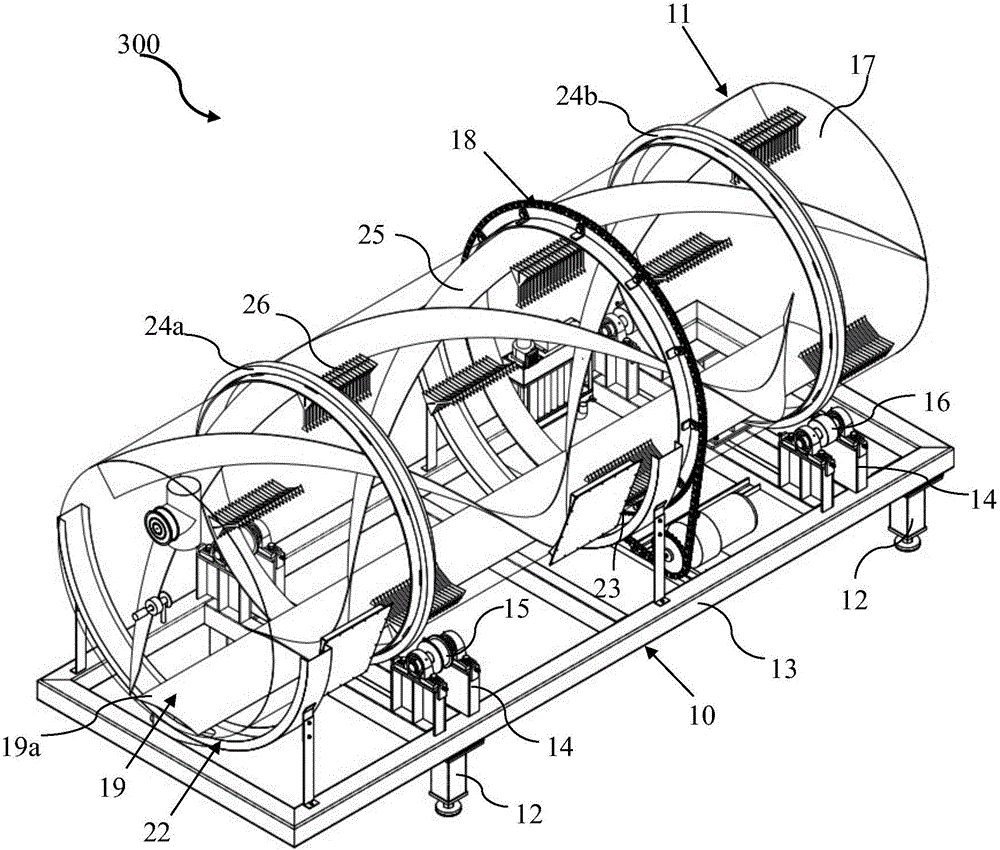

[0121] Figure 12 It is a schematic structural diagram of the biochemical treatment equipment in the second embodiment.

[0122] Such as Figure 12 As shown, the difference between the biochemical treatment equipment 400 and the biochemical treatment equipment in Embodiment 1 is that the driving part is the motor driving part 30, and the motor driving part 30 includes a reduction motor 30a, a driving gear 30b and a driven gear 30c.

[0123] The middle part of the driving gear 30b is connected with the reduction motor 30a through the rotating shaft, and the edge part is meshed with the driven gear 30c. The middle part of the driven gear 30c is installed on a side wall of the drum body through the rotating shaft.

[0124] The shape and structure of the drum body in this embodiment are the same as those in Embodiment 1, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com