Intelligent welding industrial control network operation console

A welder and intelligent technology, which is applied in the field of intelligent welding industrial control network console, can solve the problems of real-time monitoring and the incomplete realization of welding control equipment functions, and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

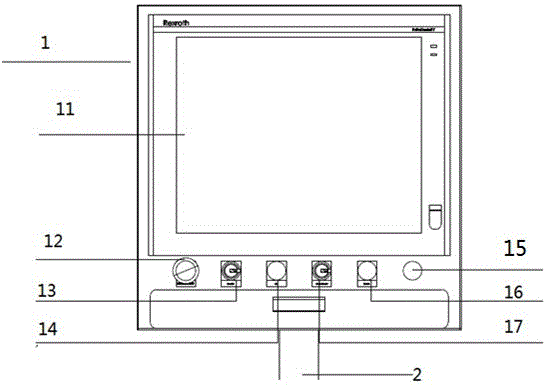

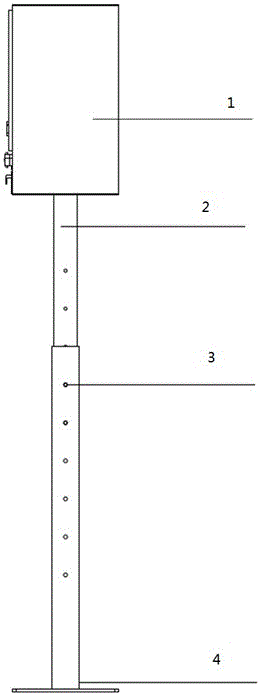

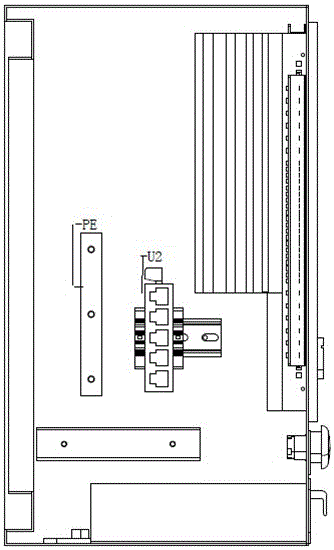

[0018] Combine below Figure 1 to Figure 4 , the present invention is further described:

[0019] An intelligent welding industrial control network operation console, including a cabinet body 1, on which a PC industrial computer 11, an emergency stop key 12, a main power switch key 13, a main power indicator light 14, a spare key 15, and a switch indicator are arranged outside the cabinet body 1 Lamp 16 and switch switch 17; inside the cabinet body 1 are provided with grounding copper bar PE, industrial network switch U2, DC power supply V1, relay K1, 220VAC terminal AX1, 220VAC terminal BX2 and 12VDC terminal X3, of which DC power supply V1, relay K1 , 220VAC terminal AX1, 220VAC terminal BX2 and 12VDC terminal X3 are sequentially connected on the same axis.

[0020] Also includes a counter, coupled to the programmable controller, which is used to count the number of abnormal situations experienced by the plurality of interfaces and the modules; when the number reaches a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com