Wheel train type movable platform for four-axis parallel robot

A robot and parallel technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high transmission noise, poor machining and installation accuracy, and fast wear and tear, and achieve the effects of reliable transmission, low operating noise and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

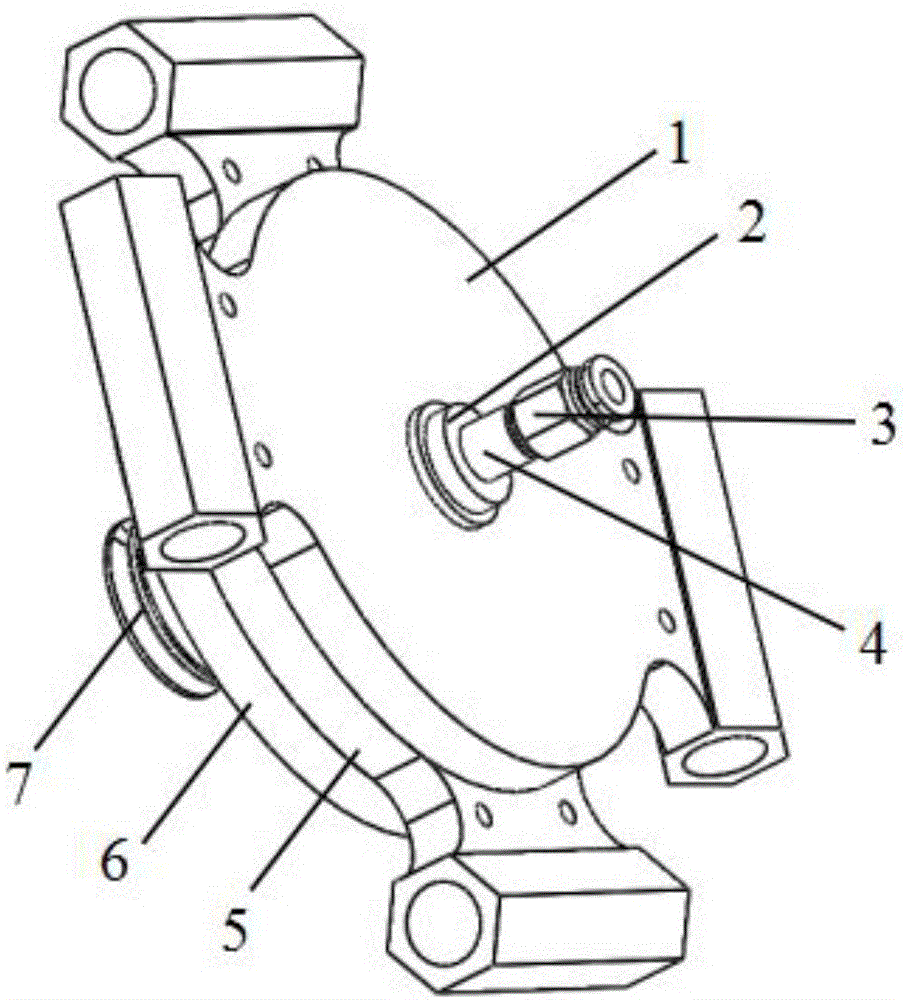

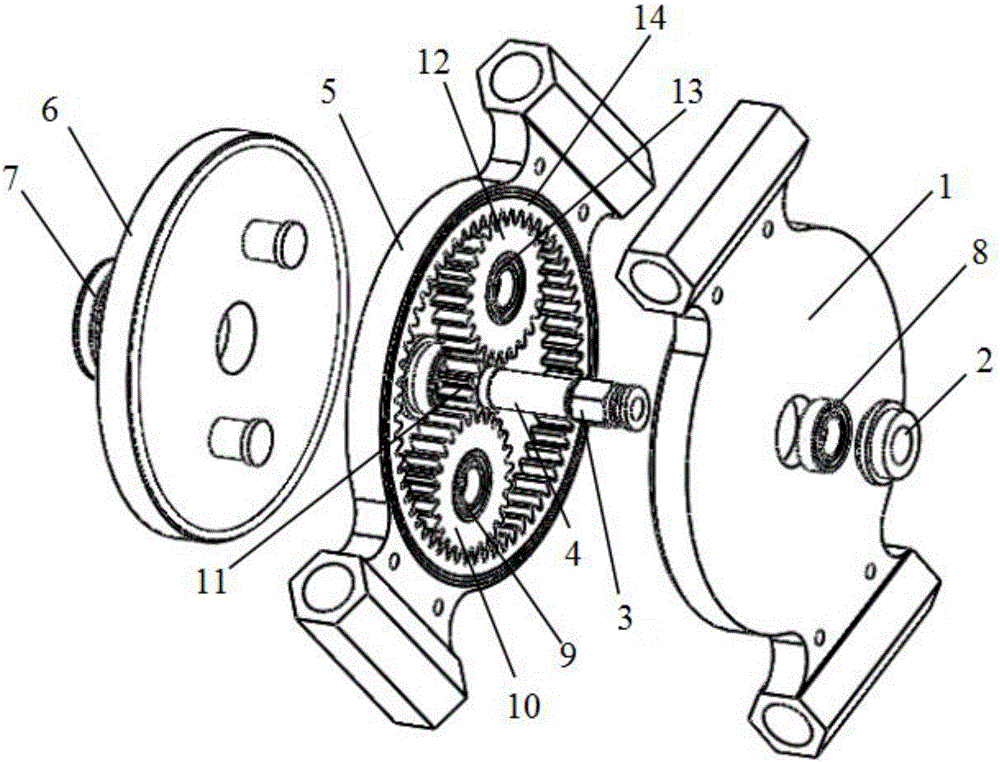

[0018] Such as figure 1 , figure 2 As shown, a wheel-train dynamic platform for a four-axis parallel robot includes a four-axis parallel mechanism, a sub-platform I1, a sub-platform II5, a gear rack 6, a gear 10, a gear 12, a center wheel 11 and a ring gear 14. The sub-platform I1 and the sub-platform II5 are respectively affixed to the lower connecting shafts 15 of two sets of opposite branch chains provided on the four-axis parallel mechanism; the ring gear 14 is affixed to the sub-platform II5, The No. 1 gear 10 and the No. 2 gear 12 are installed on the gear frame 6 through the No. 1 deep groove ball bearing 9 and the No. 2 deep groove ball bearing 13 respectively, and mesh with the ring gear 14 and the center wheel 11 respectively. , the center wheel 11 is connected to the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com