Stereoscopic bag handle inward-bending and spot-welding device

A technology of spot welding device and bag handle, which is applied in the direction of household components, household appliances, and other household appliances, etc., which can solve the problem of slow bag making speed, affecting the portability, fastness, production efficiency, and poor stability of three-dimensional bags with square bottom three-dimensional bags, etc. problem, to achieve the effect of improving speed and facilitating packing and sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

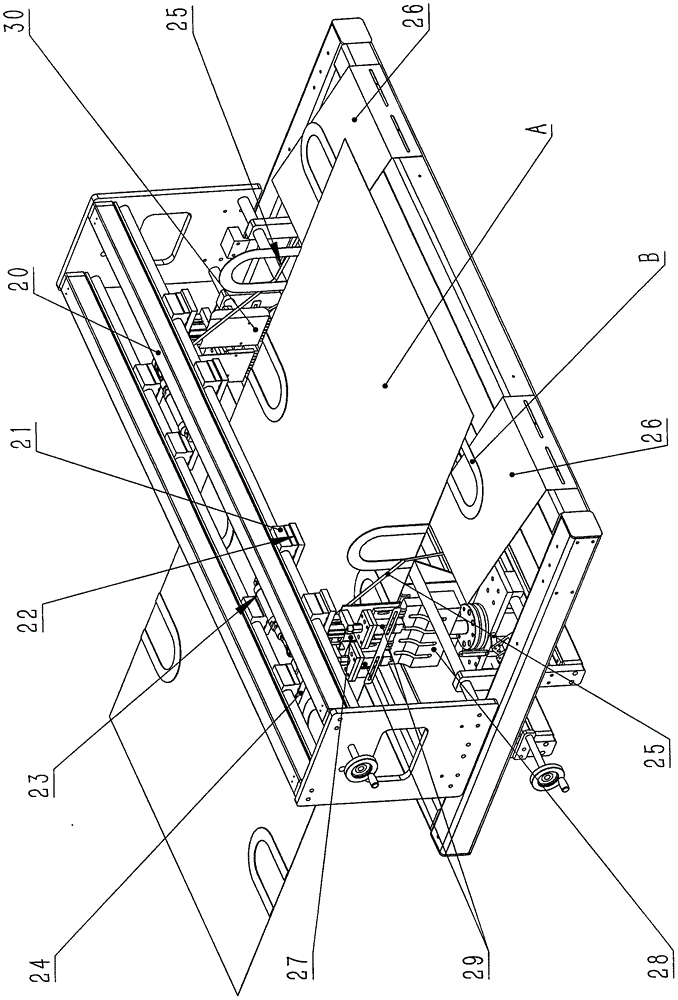

[0009] refer to figure 1 It can be known that the three-dimensional bag handle inner folding spot welding device of the present invention applied to bag making machine comprises inner folding frame 20, and inner pushing cylinder plate 22 is equipped with on both sides of the upper part of said inner folding frame 20 (by slide block 21), Inward folding cylinder 23 is housed on this inner pushing cylinder plate 22, and described inner folding cylinder 23 links to each other with inner pushing plate 24, retaining bar 25 successively (inner folding cylinder 23 links to each other with inner pushing plate 24, and the side of inner pushing plate 24 is connected with Material retaining bar 25 links to each other); Material retaining plate 26 is equipped with on the bottom both sides of described inner folding frame 20, and this material retaining plate 26 is adjacent to described material retaining bar 25, on described inner folding frame 20, And in the side place of retaining materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com