A racing downhill tire

A technology for car tires and racing, which is applied to tire parts, reinforcing layers of pneumatic tires, tire treads/tread patterns, etc. Can no longer improve the problem, to achieve the effect of reducing the amount of deformation, increasing the riding speed and safety, and improving the ranking of the competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

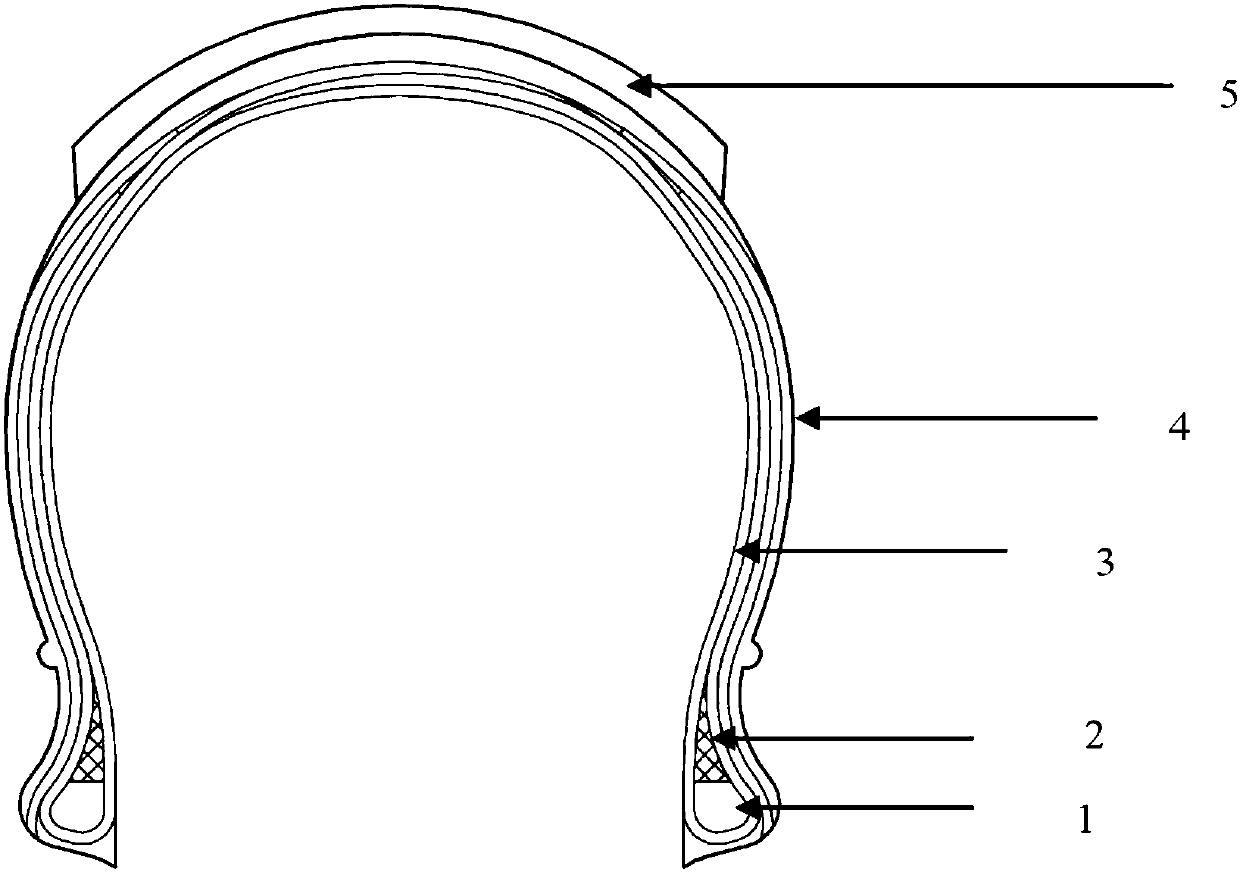

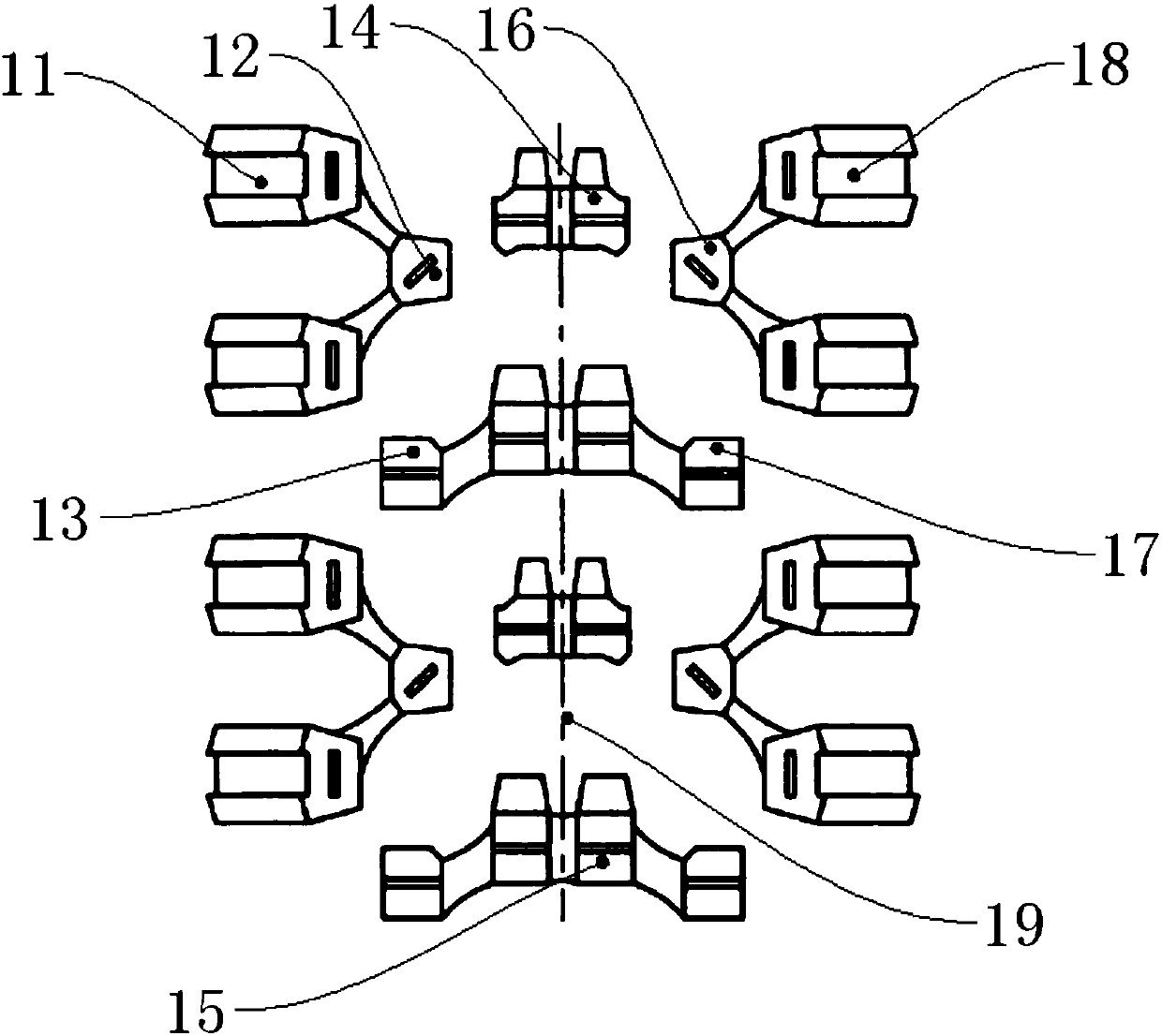

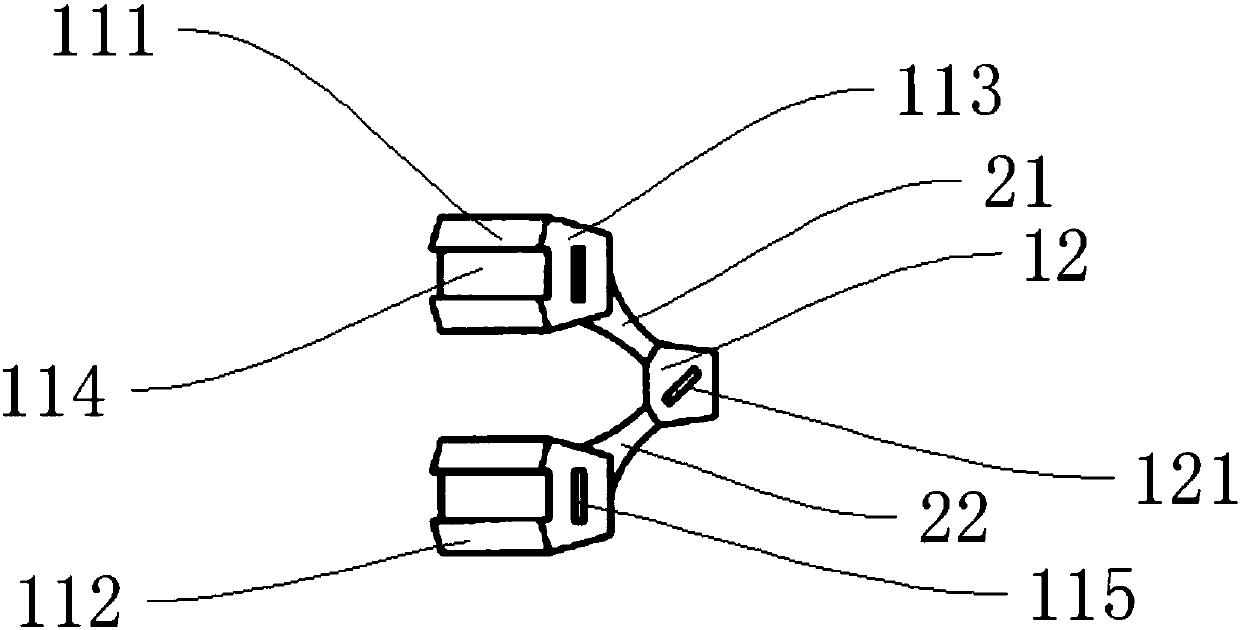

[0024] In order to achieve the purpose of the present invention, as figure 1 As shown, a racing downhill vehicle tire of the present invention comprises a steel wire 1, an apex 2 arranged sequentially from the inside to the outside, the hardness of the apex 2 is 65-73 SA, a carcass ply 3, and a bead ply 4 and tread layer 5, the steel wire 1 circles in turn to form a circle, the carcass ply 3 folds back and overlaps along the steel wire 1 to form a circle, the bead ply 4 is arranged on the outer periphery of the carcass ply 3, and the tread layer 5 is arranged on the tire On the outer periphery of the side ply layer 4, the tread layer 5 is provided with several pattern sequences distributed along the tire axis circumferential direction, the pattern sequence includes a first longitudinal pattern sequence 11, a second longitudinal pattern sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com