Multi-power-source vehicle driving method and system involved with reusable power generation system

A power generation system, source-driven technology, which is applied in the use of engine-driven traction, the arrangement of multiple different prime movers of general power plants, and electric vehicles, etc. Problems such as long battery charging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

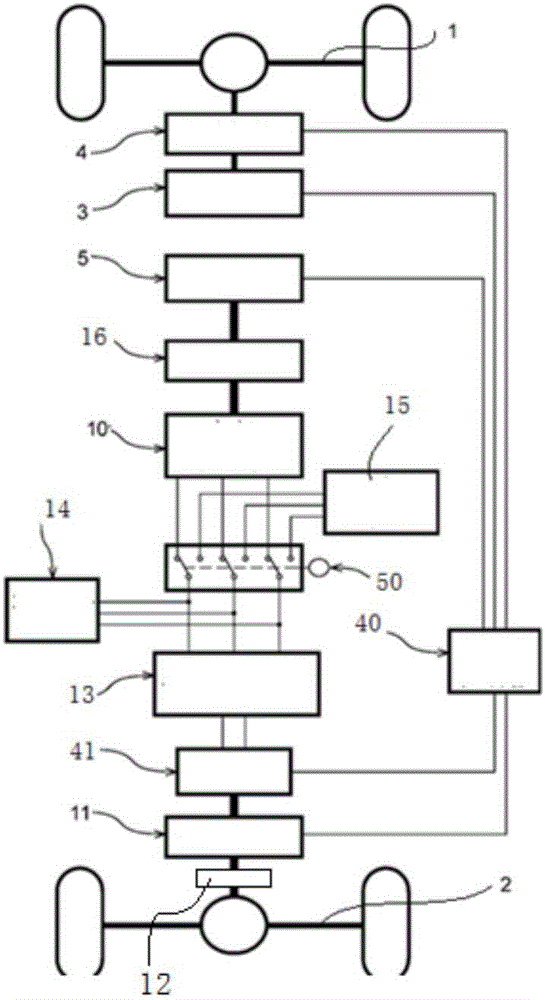

Embodiment 1

[0033] Such as figure 1 As shown, the first internal combustion engine 3 is arranged on the first axle and the transmission structure 1 on the axle is arranged on the vehicle frame close to the first axle and the transmission structure 1 on the axle. The power output of the first internal combustion engine 3 is connected to the transmission device 4, the transmission device 4 includes a gearbox, and the power output of the transmission device 4 is connected to the transmission structure on the axle. In this way the first internal combustion engine 3 can directly drive the first axle. Of course, a clutch can be set between the first internal combustion engine 3 and the gearbox, or between the gearbox and the transmission structure on the vehicle axle according to requirements.

[0034] The drive motor 11 is arranged on the vehicle frame close to the second axle and the transmission structure 2 on the axle. The power output of the second internal combustion engine 5 is connect...

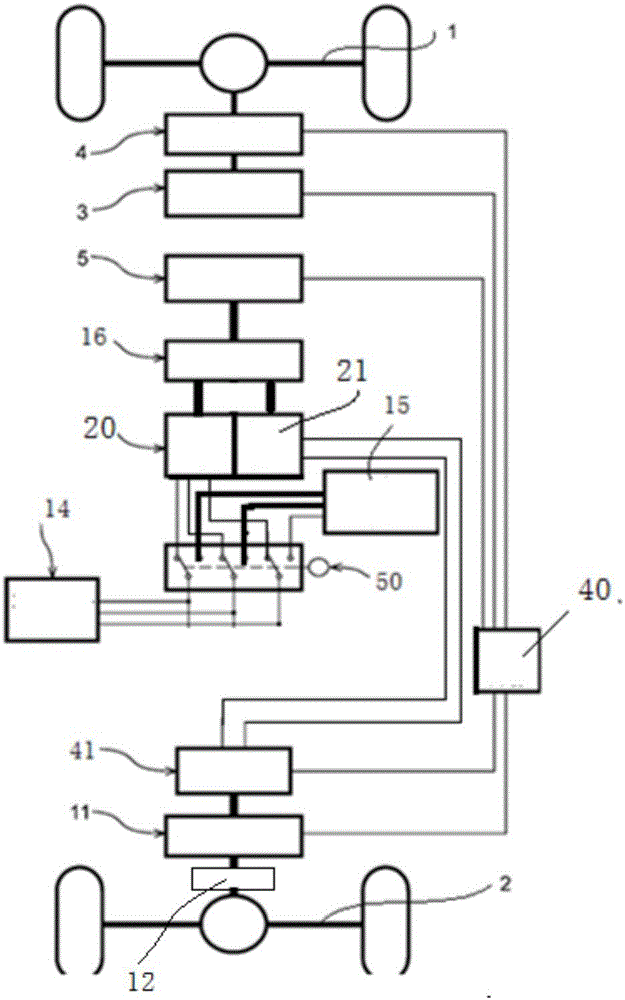

Embodiment 2

[0036] Such as figure 2 As shown, the first internal combustion engine 3 is arranged on the first axle and the transmission structure 1 on the axle is arranged on the vehicle frame close to the first axle and the transmission structure 1 on the axle. The power output of the first internal combustion engine 3 is connected to the transmission device 4, the transmission device 4 includes a gearbox, and the power output of the transmission device 4 is connected to the transmission structure on the axle. In this way the first internal combustion engine 3 can directly drive the first axle. Of course, a clutch can be set between the first internal combustion engine 3 and the gearbox, or between the gearbox and the transmission structure on the vehicle axle according to requirements.

[0037] The drive motor 11 is arranged on the vehicle frame close to the second axle and the transmission structure 2 on the axle. The power output of the second internal combustion engine 5 is connec...

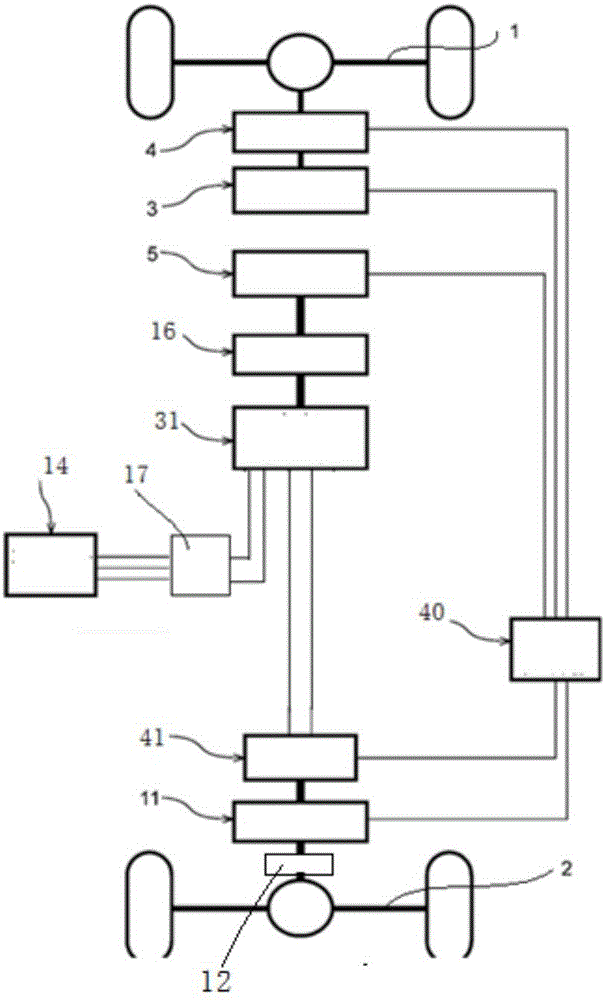

Embodiment 3

[0039] Such as image 3 As shown, the first internal combustion engine 3 is arranged on the first axle and the transmission structure 1 on the axle is arranged on the vehicle frame close to the first axle and the transmission structure 1 on the axle. The power output of the first internal combustion engine 3 is connected to the transmission device 4, the transmission device 4 includes a gearbox, and the power output of the transmission device 4 is connected to the transmission structure on the axle. In this way the first internal combustion engine 3 can directly drive the first axle. Of course, a clutch can be set between the first internal combustion engine 3 and the gearbox, or between the gearbox and the transmission structure on the vehicle axle according to requirements.

[0040] The drive motor 11 is arranged on the vehicle frame close to the second axle and the transmission structure 2 on the axle. The power of the second internal combustion engine 5 is output and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com