Preparation method of fullerene derivative film with micron flower shape

A technology of fullerene derivatives and methylene fullerene, which is applied in the direction of hydrocarbon production from halogen-containing organic compounds, nanotechnology, organic chemistry, etc., can solve the problems of reducing the electron transmission efficiency of C60, and achieve high utilization rate , The preparation process is simple, the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

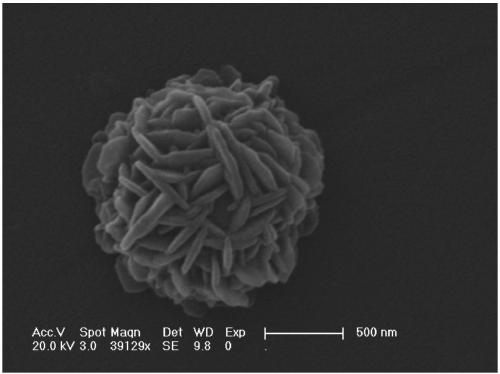

[0032] Weigh 144mg C 60 Place in a 500mL custom-made three-port electrolytic cell, and add 100mL of benzonitrile solution containing 0.1M tetrabutylammonium perchlorate (TBAP). The glassy carbon electrode is used as the working electrode, the platinum mesh electrode is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode, respectively inserted into the electrolytic cell. Magnetic stirring, under the protection of nitrogen, controlled potential electrolysis at -1.1V voltage to electrolysis, the solution gradually changed from lavender to dark red. to C 60 is fully electrolyzed C 60 2- , to stop electrolysis. Quickly add 10-50 times of PhCHBr to the reaction solution 2 , the solution changed from dark red to dark green, and then gradually turned to brownish yellow. The reaction was stirred vigorously for 50 min, and the reaction was stopped. The reaction solution was transferred to a round bottom flask, and the solvent was ...

Embodiment 2

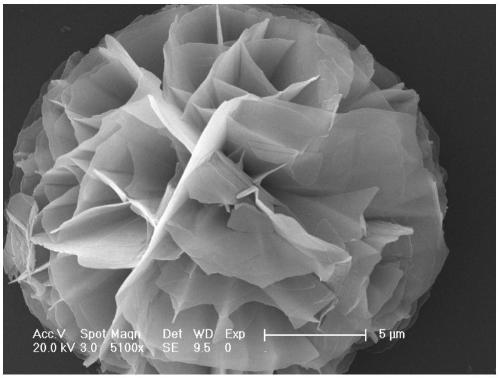

[0035] Accurately weigh 20mg of 1,2-(phenyl)methylenefullerene C 60 , placed in a 25mL ground-neck Erlenmeyer flask, add 10mL of m-xylene, ultrasonically dissolve for 5min, and make 2mg / mL of 1,2-(phenyl)methylenefullerene C 60 - m-xylene solution, set aside. Cut glass slides into 1cm×1cm squares with a glass knife, ultrasonically clean them three times with acetone, deionized water, and ethanol, and finally dry them with nitrogen. Use a pipette gun to accurately pipette 20 μL of the above 2 mg / mL 1,2-(phenyl)methylenefullerene C 60 -Meta-xylene solution, drop-coated on the surface of the glass sheet, and let it dry naturally. For SEM testing such as figure 2 .

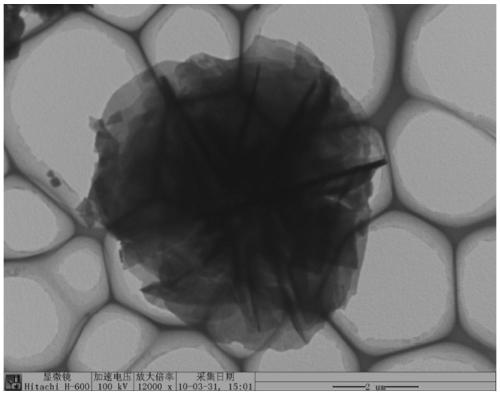

[0036] The prepared 1,2-(phenyl)methylenefullerene C 60 The glass sheet film was placed in a muffle furnace, heated to 330°C, kept at the temperature for 10 minutes, and then lowered to room temperature. Scanning electron microscope tests such as Figure 4 .

Embodiment 3

[0038] Accurately pipette 10 μL of the 2 mg / mL 1,2-(phenyl)methylenefullerene C of Example 2 with a pipette gun 60 -Meta-xylene solution, drop-coated on the copper grid. Allow to dry for TEM testing such as image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com