A method for preparing carbon nanosheets containing hierarchical structure from biomass

A carbon nanosheet and biomass technology, applied in the field of materials, can solve problems such as harsh reaction conditions and environmental pollution, and achieve the effects of solving cost, large-scale preparation, simple and controllable reaction process, and low-cost controllable preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

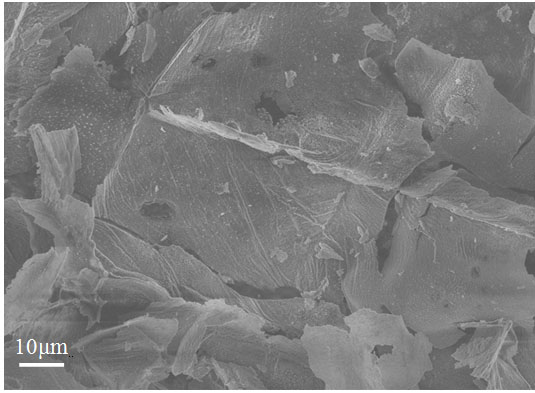

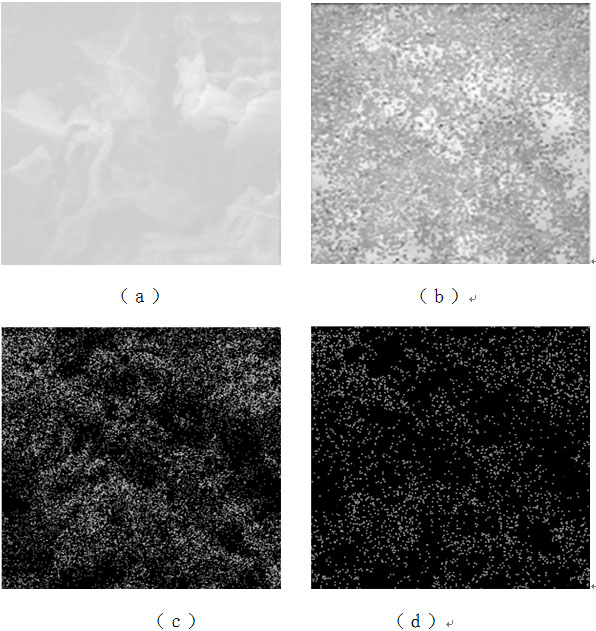

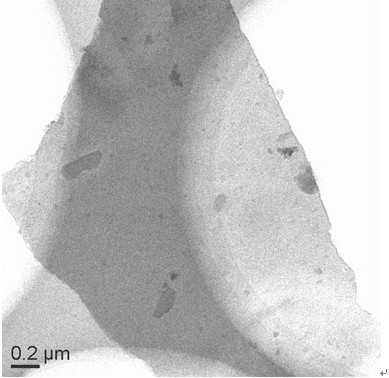

Embodiment 1

[0018] (1) Cut an appropriate amount of radish into pieces and wash with water, then soak in deionized water for 1 h;

[0019] (2) The radish obtained in step (1) is quickly frozen with liquid nitrogen, and freeze-dried in a freeze dryer;

[0020] (3) The dried radish obtained in step (2) was calcined in an air atmosphere at 260 °C for 1 h to obtain a hierarchical carbon material. The heating rate during the calcination process was 10°C / min, and the initial temperature was room temperature; after the calcination, the samples were naturally cooled in an air atmosphere.

Embodiment 2

[0022] (1) Cut an appropriate amount of orange peel into strips, wash with water, and soak in deionized water for 1 hour;

[0023] (2) The orange peel obtained in step (1) is quickly frozen with liquid nitrogen, and freeze-dried in a freeze dryer;

[0024] (3) The dried orange peel obtained in step (2) was calcined in an air atmosphere at 270 °C for 1 h to obtain a hierarchical carbon material. The heating rate during the calcination process was 10°C / min, and the initial temperature was room temperature; after the calcination, the samples were naturally cooled in an air atmosphere.

Embodiment 3

[0026] (1) Cut an appropriate amount of banana peel into pieces and wash with clean water, then soak in deionized water for 1 h;

[0027] (2) The banana peel obtained in step (1) is quickly frozen with liquid nitrogen, and freeze-dried in a freeze dryer;

[0028] (3) The dried banana peel obtained in step (2) was calcined in an air atmosphere at 280 °C for 1 h to obtain a hierarchical carbon material. The heating rate during the calcination process was 10°C / min, and the initial temperature was room temperature; after the calcination, the samples were naturally cooled in an air atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com