Method for layer-layer self-assembling and fixing biological active factor on tissue engineering material

A bioactive factor and tissue engineering technology, applied in medical science, prosthesis, etc., can solve the problems of unable to achieve stable fixation of bioactive factors, loss of biological activity of bioactive factors, etc., and achieve the effect of simple and feasible process and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

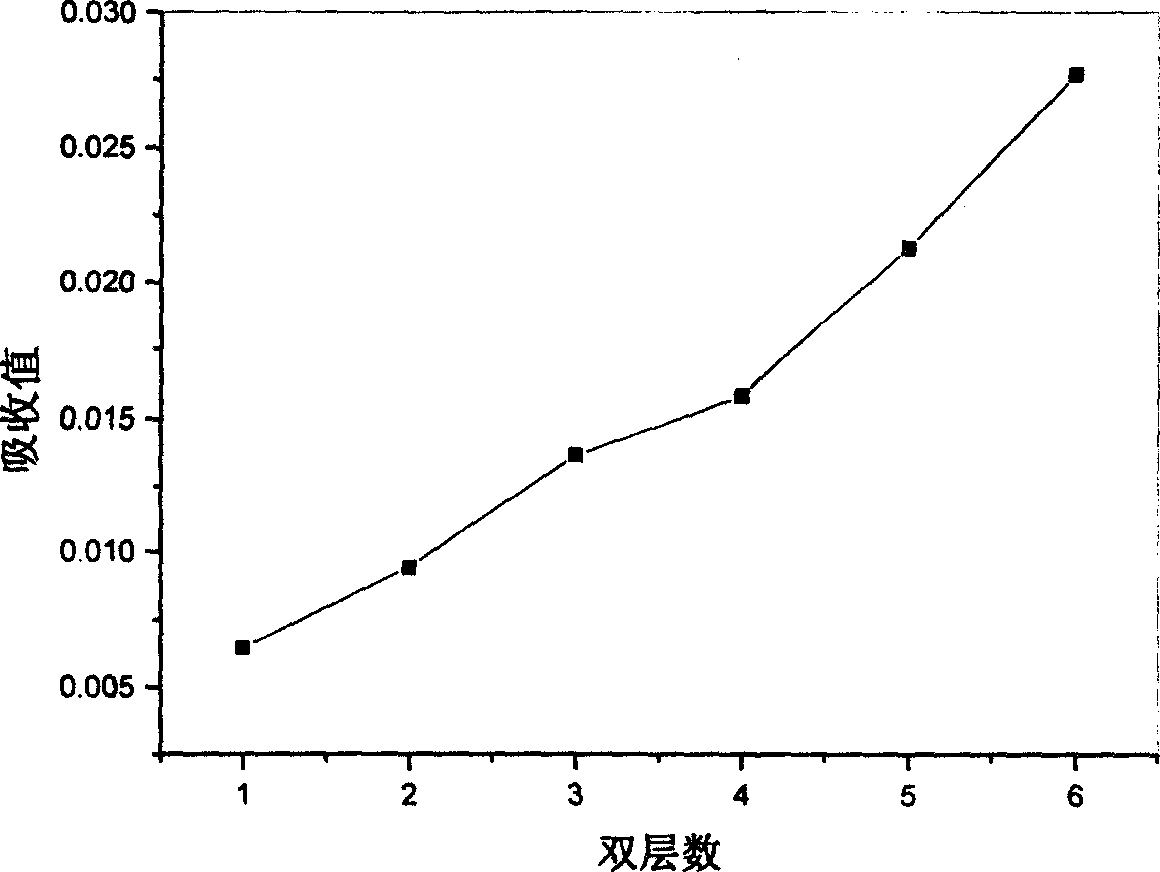

[0027] Embodiment 1: UV-Vis spectrum characterizes the process of quartz surface layer-layer self-assembly basic fibroblast growth factor (bFGF) / chondroitin sulfate (CS)

[0028] Soak the quartz glass grafted with KH-550 in 3% acetic acid solution for 15 minutes to protonate (ie cationize) the amino groups on the surface of the quartz glass, and then put it into 0.1M chondroitin sulfate containing 1mg / ml Soak in NaCl solution for 15 minutes. The quartz glass assembled with a layer of chondroitin sulfate was put into 0.1M NaCl solution and rinsed 3 times for 2 minutes each time. After rinsing, the quartz glass was soaked in a PBS solution (pH 7.4) of 10 μg / ml rhodamine-labeled bFGF (Rd-bFGF) for 15 minutes, and then rinsed 3 times with PBS (pH 7.4), each time Rinse for 2 minutes. By repeating the above steps, a quartz glass surface assembled with multilayer bFGF / CS can be obtained. After each double layer was assembled, the absorption of Rd-bFGF at 560 nm was detected by UV-...

Embodiment 2

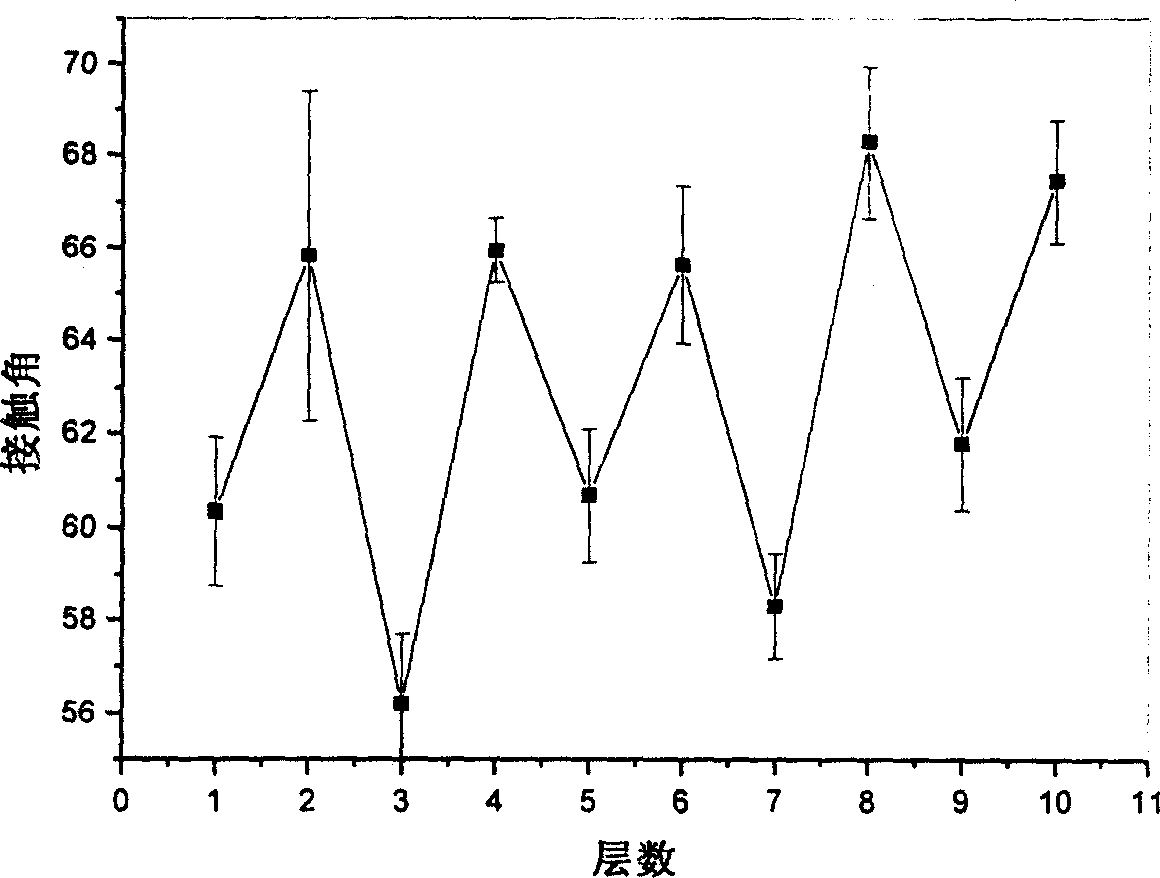

[0029] Example 2: The contact angle measurement instrument characterizes the process of quartz surface layer-layer self-assembly basic fibroblast growth factor (bFGF) / chondroitin sulfate (CS)

[0030] Soak the quartz glass grafted with KH-550 in 3% acetic acid solution for 15 minutes to protonate (ie cationize) the amino groups on the surface of the quartz glass, and then put it into 0.1M chondroitin sulfate containing 1mg / ml Soak in NaCl solution for 15 minutes. The quartz glass assembled with a layer of chondroitin sulfate was put into 0.1M NaCl solution and rinsed 3 times for 2 minutes each time. After rinsing, the quartz glass was soaked in 10 μg / ml bFGF in PBS solution (pH value 7.4) for 15 minutes, and then rinsed with PBS solution (pH value 7.4) for 3 times, each time for 2 minutes. By repeating the above steps, a quartz glass surface assembled with multilayer bFGF / CS can be obtained. Each assembled layer was measured with a surface tensiometer to measure the change o...

Embodiment 3

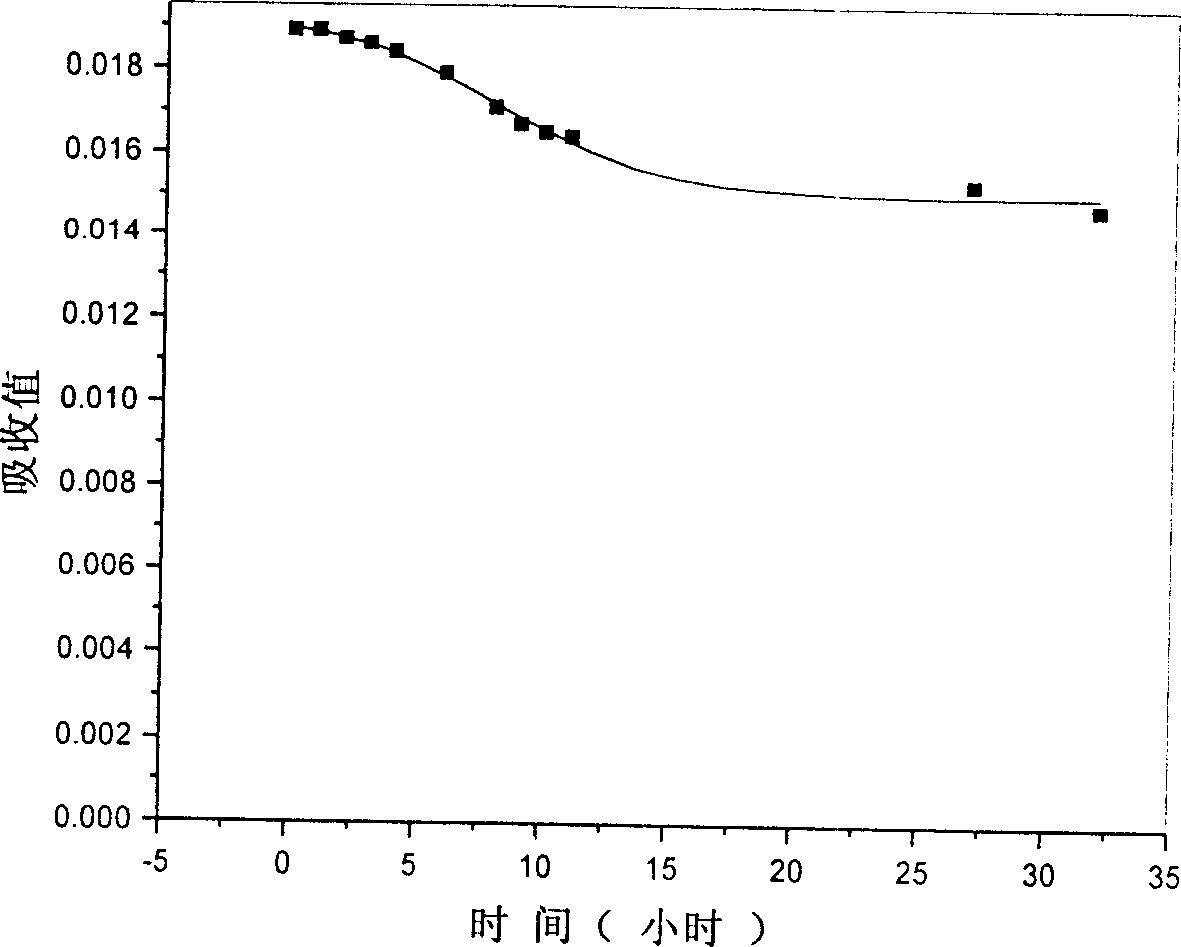

[0031] Embodiment 3: UV-visible spectrum evaluates the stability of basic fibroblast growth factor (bFGF) / chondroitin sulfate (CS) multilayer film on quartz surface

[0032] Soak the quartz glass grafted with KH-550 in 3% acetic acid solution for 15 minutes to protonate (ie cationize) the amino groups on the surface of the quartz glass, and then put it into 0.1M chondroitin sulfate containing 1mg / ml NaCl solution for 15 minutes. The quartz glass assembled with a layer of chondroitin sulfate was put into 0.1M NaCl solution and rinsed 3 times for 2 minutes each time. After rinsing, the quartz glass was soaked in a PBS solution (pH 7.4) of 10 μg / ml rhodamine-labeled bFGF (Rd-bFGF) for 15 minutes, and then rinsed 3 times with PBS (pH 7.4), each time Rinse for 2 minutes. Repeat the above steps to obtain a quartz glass surface with 10 layers of Rd-bFGF / CS assembled. It was soaked in PBS buffer solution, and the ultraviolet-visible absorption of Rd-bFGF on the quartz glass surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com