Fullerene nano fiber film, porous carbon fiber film and preparation method thereof

A technology of porous carbon fiber and nanofiber, which is applied in the direction of nano-carbon and fullerene, can solve the problems of low film-forming efficiency, expensive film-forming equipment, and complicated operation steps, so as to simplify the operation steps, improve the film-forming efficiency, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

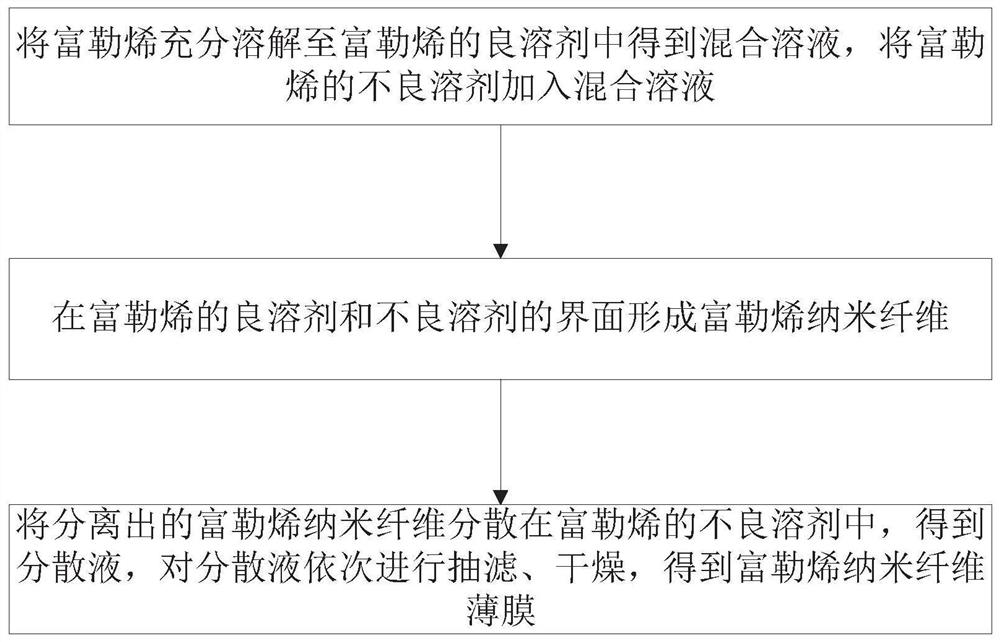

[0039] Such as figure 1 Shown, a kind of preparation method of fullerene nanofiber film comprises the steps:

[0040] (1) Fully dissolving fullerene into a good solvent of fullerene to obtain a mixed solution, adding a poor solvent of fullerene to the mixed solution, forming fullerene nanofibers at the interface of a good solvent of fullerene and a poor solvent ;

[0041] (2) Dispersing the separated fullerene nanofibers in a poor solvent of fullerenes to obtain a dispersion liquid, which is sequentially suction-filtered and dried to obtain a fullerene nanofiber film.

[0042] Further, the specific implementation of the suction filtration is:

[0043] A filter membrane is placed on the mouth of the suction filter bottle, and the dispersion liquid is poured into the filter membrane at one time, so that it is evenly dispersed on the filter membrane, and fullerene nanofiber films of different sizes are obtained by changing the caliber of the suction filter bottle. The ratio of t...

Embodiment 1

[0046] A method for preparing a fullerene nanofiber film and a porous carbon fiber film derived therefrom, comprising the steps of:

[0047] Step 1: First add 4mg C 60 Dissolve in 2ml m-xylene, ultrasonic 20min to make C 60 Fully dissolve, then slowly inject 4ml of isopropanol into the above-mentioned mixed solution along the wall of the sample bottle, and stand at room temperature for 24h to observe that the fullerene nanofibers appear in the mixture of m-xylene (good solvent) and isopropanol. (Poor solvent) at the interface; Wash the above-mentioned one-dimensional fullerene nanofiber more than 3 times repeatedly with isopropanol afterwards, avoid the destruction to fiber to remove residual solvent molecule, finally the fiber of gained is dispersed in isopropanol middle.

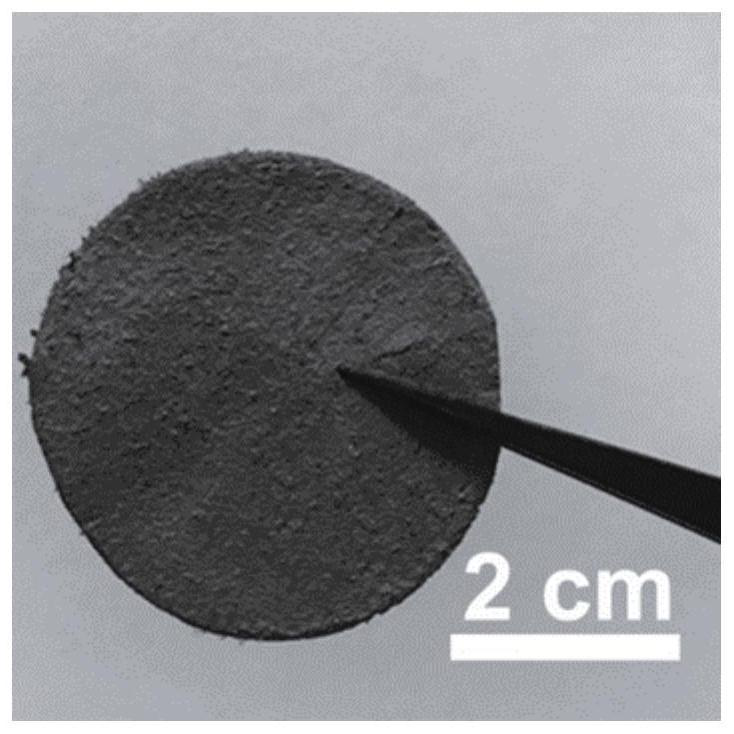

[0048] Step 2: 50 mg of C obtained in Step 1 60 The dispersion solution in isopropanol is simply suction filtered, and the diameter of the suction filter bottle is 5 cm, to obtain a wet fullerene nanofi...

Embodiment 2

[0051] A method for preparing a fullerene nanofiber film and a porous carbon fiber film derived therefrom, comprising the steps of:

[0052] Step 1: First add 4mg C 70 Dissolve in 2ml pyridine, sonicate for 20min to make C 70 Fully dissolve, then slowly inject 4ml of isopropanol into the above-mentioned mixed solution along the wall of the sample bottle, leave it at room temperature for 24h to observe that fullerene nanofibers appear in pyridine (good solvent) and isopropanol (bad solvent) Solvent) at the interface; then repeatedly wash the above-mentioned one-dimensional fullerene nanofibers with isopropanol more than 3 times to remove residual solvent molecules to avoid damage to the fibers, and finally the resulting fibers are dispersed in isopropanol.

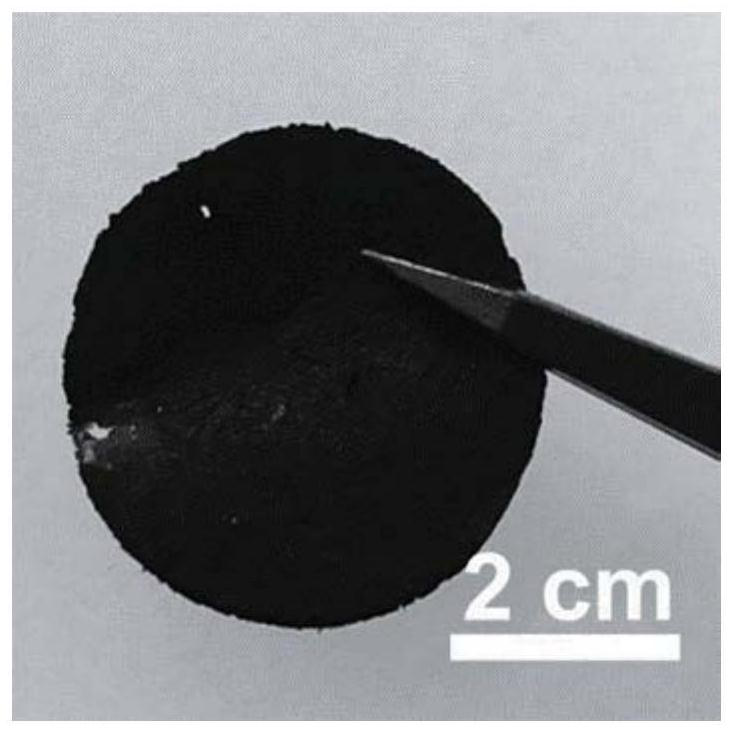

[0053] Step 2: 60 mg of C obtained in Step 1 70 The dispersion solution in isopropanol was subjected to a simple suction filtration process, and the caliber of the suction filtration bottle was 5 cm to obtain a wet fuller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com