Method of reducing salt coagulation and corrosion in top reflux system of steam stripping column in hydrogenation apparatus

A technology of a hydrogenation device and a stripper, which is applied in chemical instruments and methods, separation methods, and gas mixture processing, etc., can solve the problem of aggravating the degree of oil-water emulsification in the reflux tank, the unsatisfactory effect of the corrosion inhibitor, and the price of the corrosion inhibitor. expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

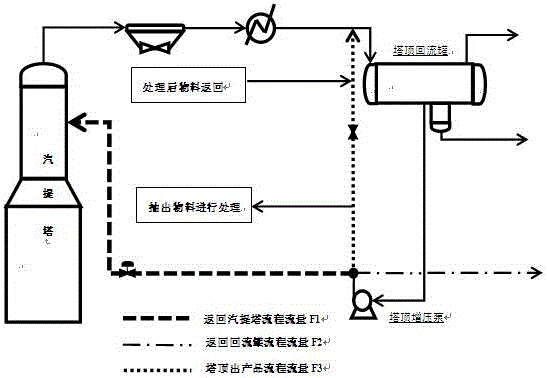

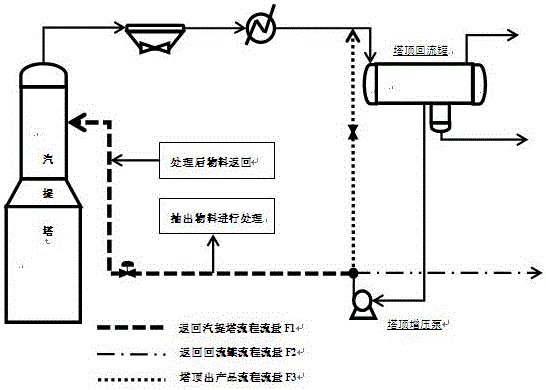

[0037] Due to the existence of sulfur, chlorine and other impurities in the feed oil of a petrochemical 3 million tons / year residual oil unit, the salt content of the circulating oil system at the top of the stripping tower is too high. With the increase of operating time, the salt content The crystallization of more salts will block the trays, air cooling, circulation pumps and pipelines, which will increase the possibility of flushing the tower, and the crystallization particles will increase the erosion and wear of the equipment, endangering safe production and increasing the difficulty of operation. At the same time, corrosion occurs in air cooling, heat exchangers, booster pumps, pipelines, etc. in the stripping tower top reflux system. The oil salt content of the top reflux of the stripper was measured to be about 6 mg / L.

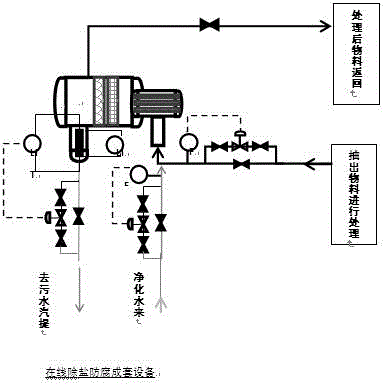

[0038] In order to reduce the corrosion of the tower top pipe and heat exchanger, the device uses intermittent water injection on the pipeline flow b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com