Energy storage device

An energy storage device and power storage technology, applied in elastic engines, machines/engines, mechanical equipment, etc., can solve the problems of volume, weight, cost, process, and safety constraints of energy storage devices, and achieve light weight, low cost, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

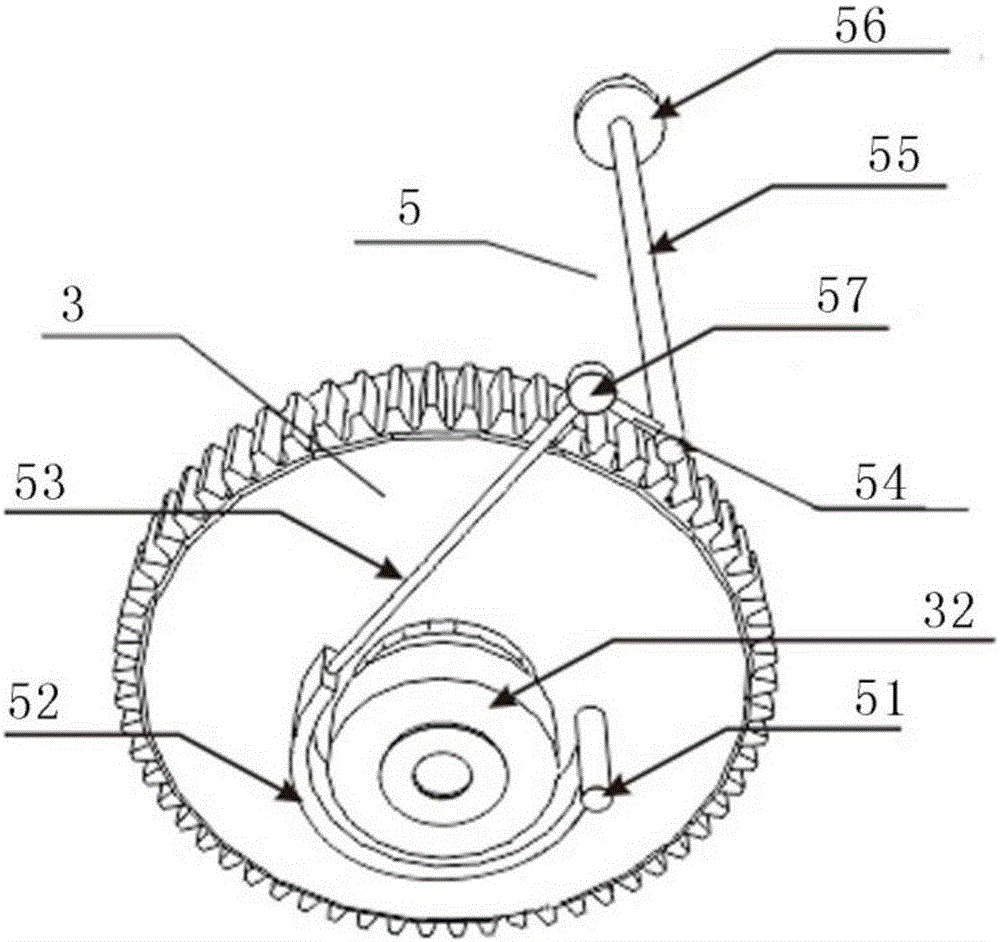

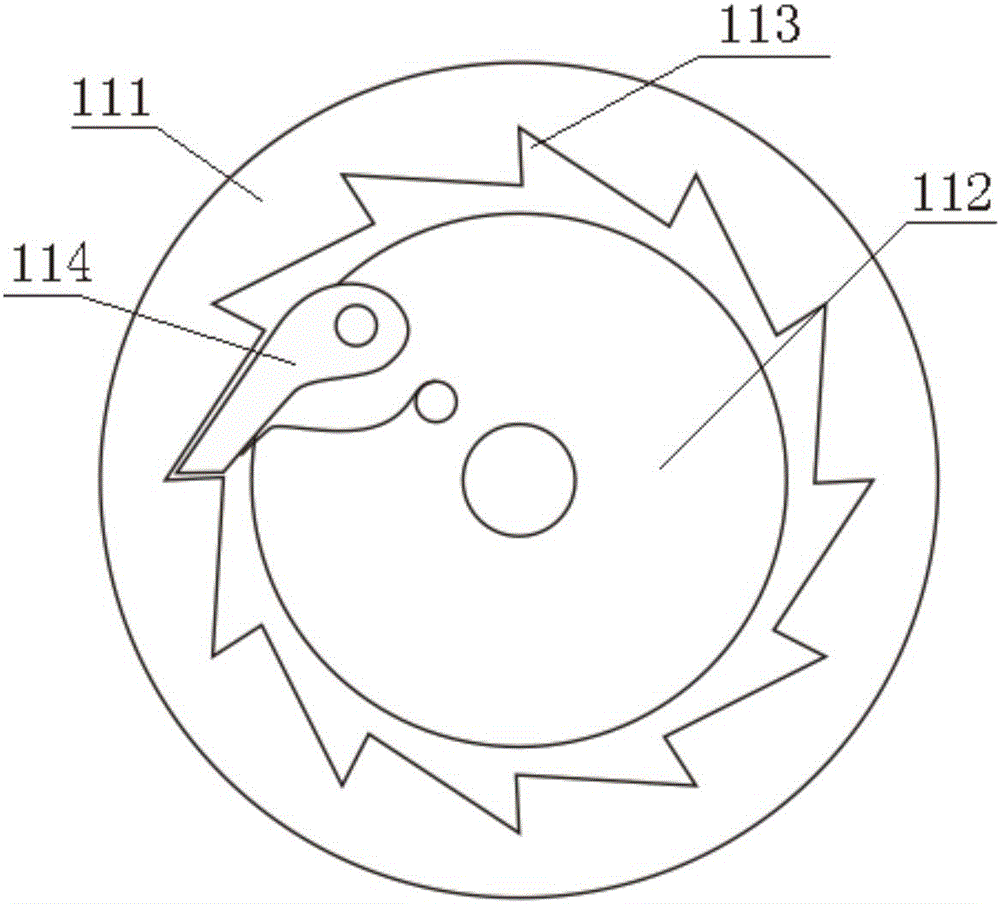

[0054] The power storage connecting plate assembly 2 of this embodiment has two implementation modes, specifically as follows:

Embodiment approach 1

[0055] Embodiment 1: The power storage connection plate assembly 2 includes a connection plate, and the power storage elastic piece assembly 4 includes a power storage elastic piece; one end surface of the connection plate is rotatably connected to one end surface of the power storage assembly 1 , the other end of the connection plate is rotatably connected to one end of the release gear 3, there is a gap between the connection plate and the release gear 3, and the power storage shrapnel is fixedly installed in the gap. In this embodiment, the energy storage function can be realized through a connection plate and a force storage shrapnel.

Embodiment approach 2

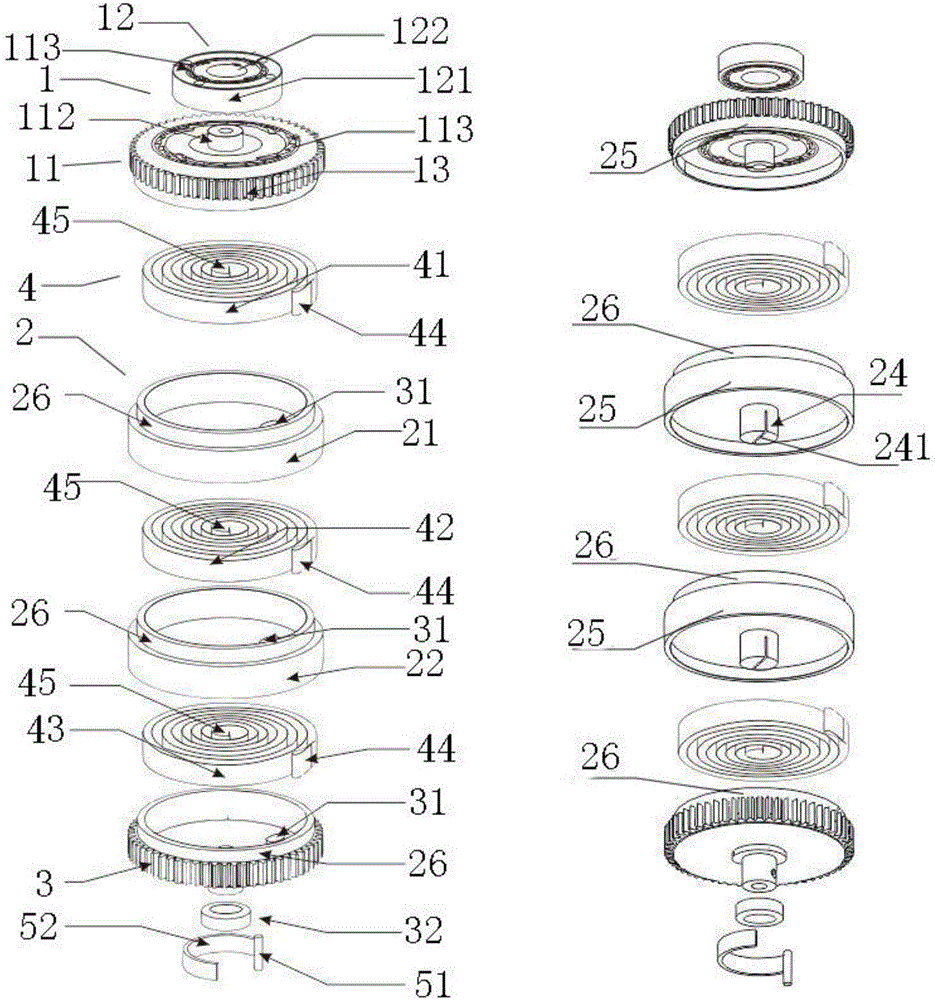

[0056] Embodiment 2: The power storage connecting disc assembly 2 includes a plurality of connecting discs which are sequentially rotated and connected, and the power storage shrapnel assembly 4 includes a plurality of power storage shrapnels for converting the kinetic energy of the power storage assembly 1 into its own elastic force; There is a gap between two adjacent connection plates; in this embodiment, multiple connection plates and multiple power storage shrapnels can be provided to realize multi-stage force storage.

[0057] The plurality of connection plates are respectively the first connection plate 21, the second connection plate 22, ..., the n-1th connection plate and the nth connection plate, which are sequentially rotated and connected. Force shrapnel 41, the second power storage shrapnel 42, the third power storage shrapnel 43, ..., the n-2th power storage shrapnel and the n-1th power storage shrapnel;

[0058] One end face of the first connecting plate 21 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com