A pump body structure capable of improving fluid flow conditions in a vortex pump

A technology of internal fluid and vortex pumps, which is applied to parts of pumping devices for elastic fluids, liquid fuel engines, pumps, etc., and can solve the problem of disordered flow in the outlet cavity, affecting the overall efficiency of the pump, and turbulence in the flow of vortex pumps and other problems, to achieve the effect of being convenient for large-scale application, simple and reasonable structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

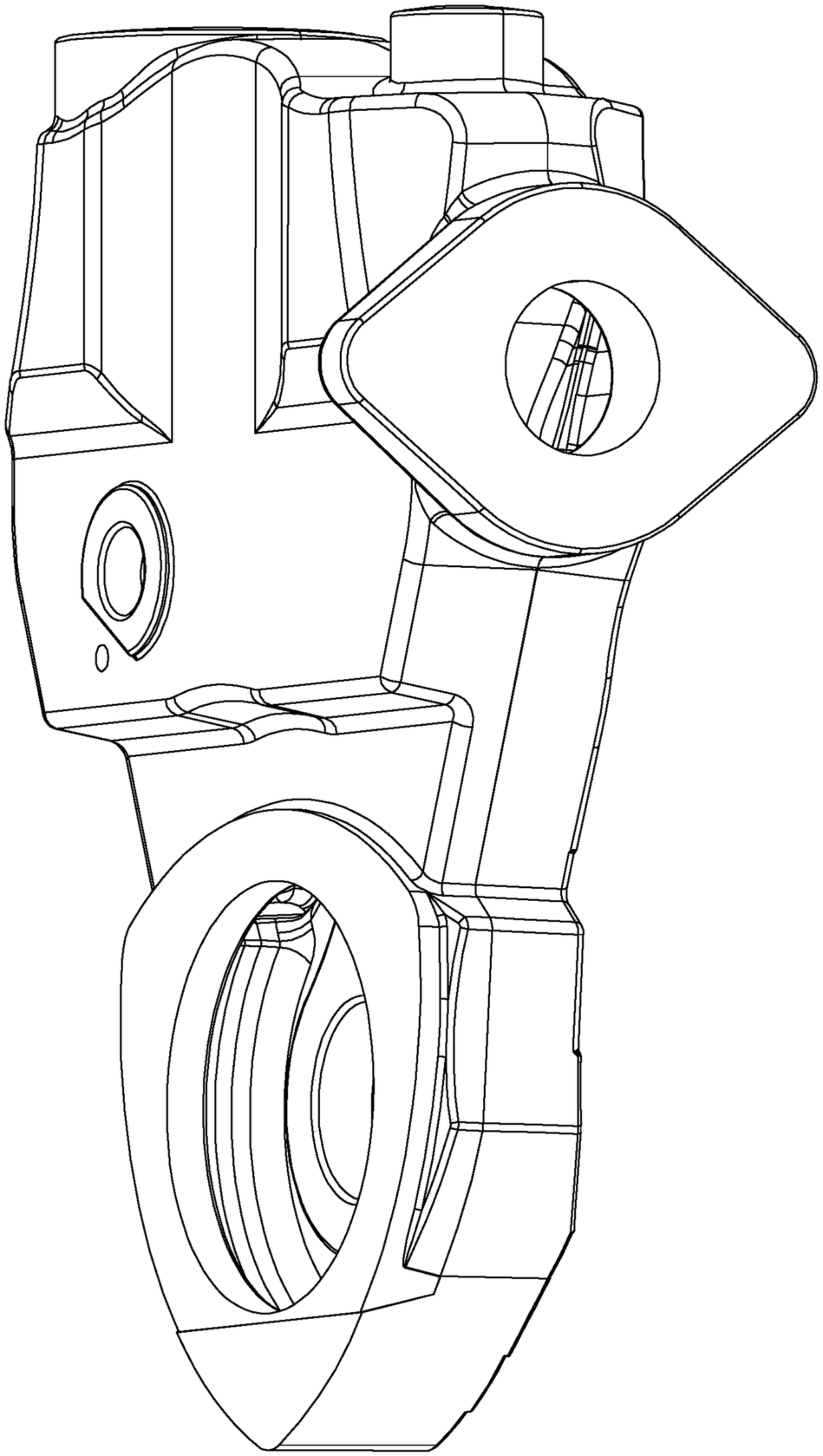

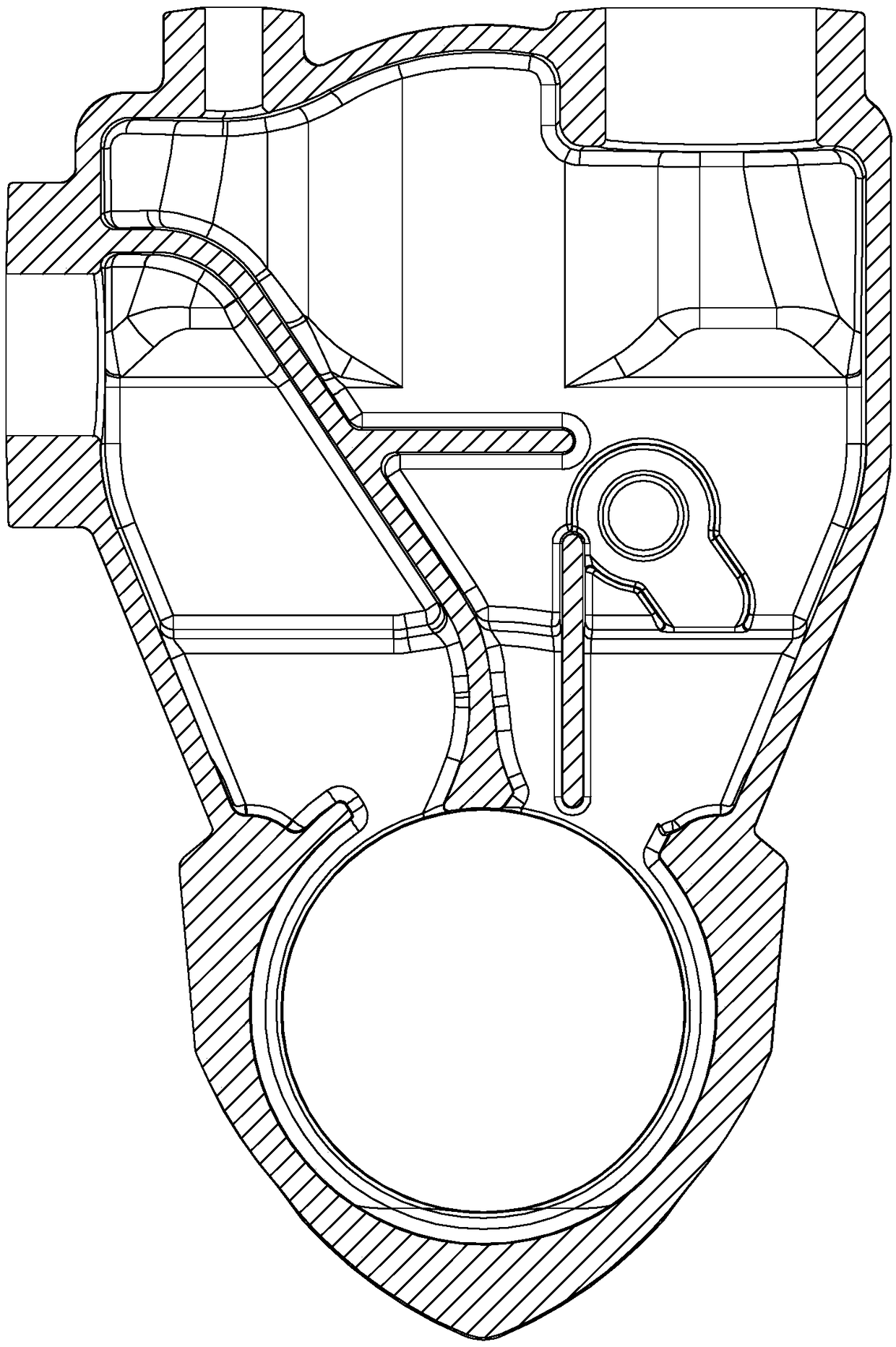

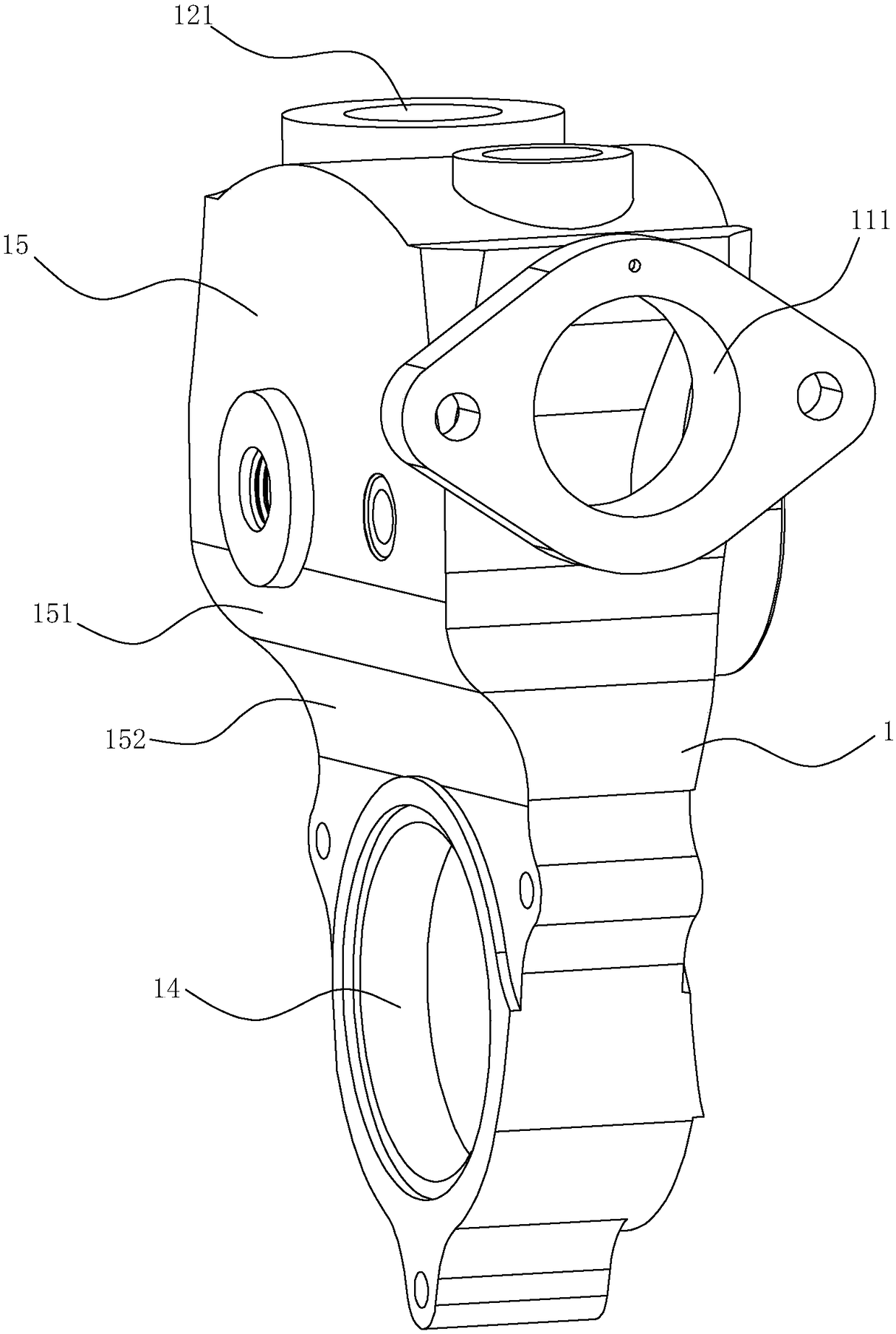

[0022] Such as Figure 3-5 As shown, the pump body structure of this embodiment that can improve the fluid flow in the vortex pump includes a body 1 with an inner cavity 10, and the inner cavity 10 is provided with a water inlet volute chamber 11 and an outlet volute. The partition tongue 13 of the chamber 12, the lower part of the body 1 has a flow channel 14 for installing the impeller which communicates with the water inlet volute 11 and the water outlet volute 12 respectively. One side of the water inlet volute 11 has a water inlet 111, and the water outlet The top of the volute 12 has a water outlet 121 .

[0023] In this embodiment, the upper part of one side of the main body 1 extends outward to form a boss 15 , the bottom edge of the boss 15 is shaped as a first arc surface 151 that arches outward, and the side of the main body 1 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com