A Sampling Tool for Quantitative Determination of Oil Spill Film Thickness

A technology for quantitative determination of oil film thickness, applied in measuring devices, instruments, etc., can solve problems such as accurate estimation of difficult oil spills, and achieve the effects of improving monitoring accuracy, high accuracy, and simple and easy methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

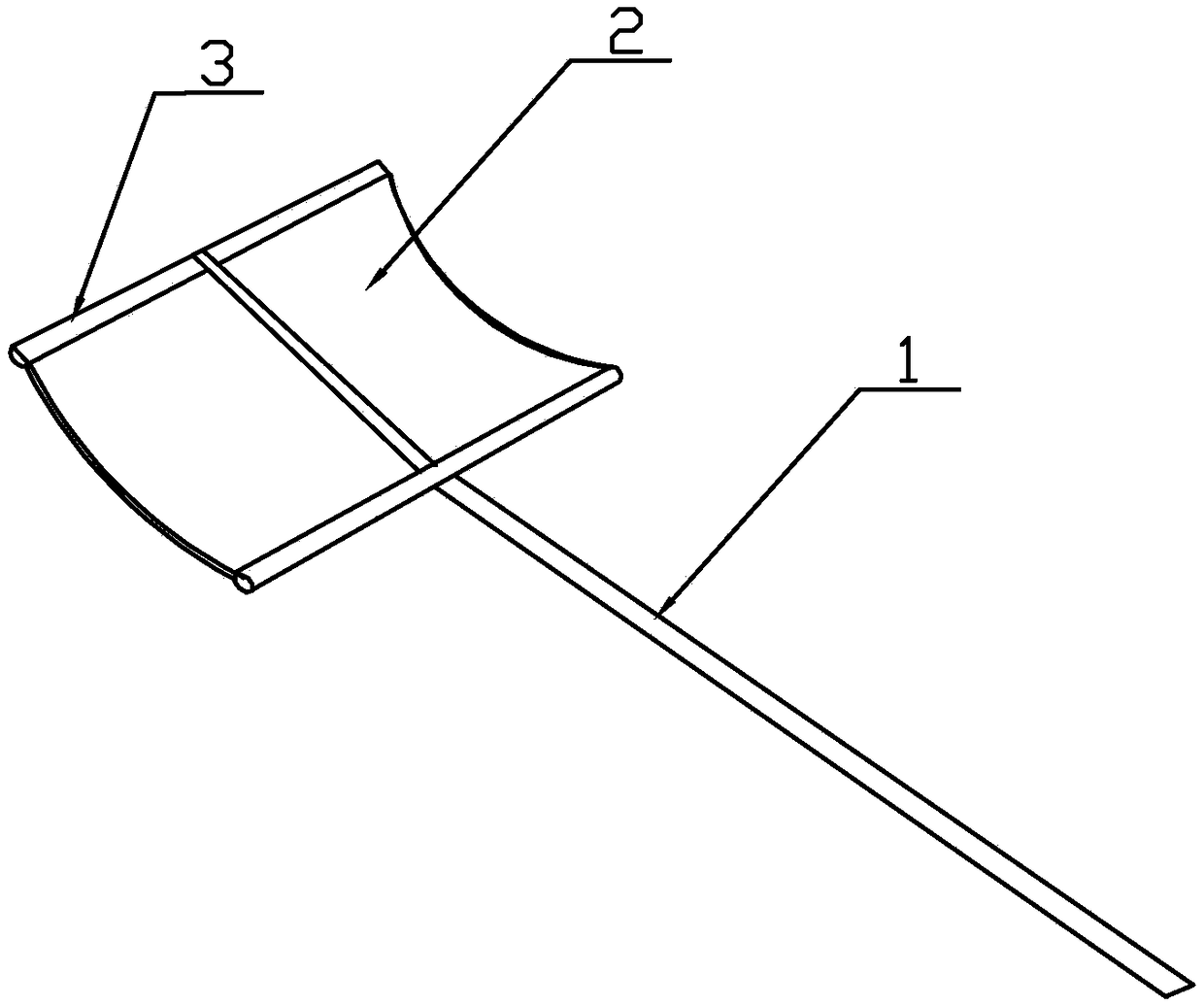

[0037]A sampling tool capable of quantitatively measuring the thickness of an oil spill film, comprising a handle 1, a screen 2 and a screen frame 3, the screen 2 is in the shape of a dustpan, and the mesh aperture of the screen is 0.1mm. Set on the screen frame, the screen is connected with the screen frame along the edge of the screen frame, the gap formed between the screen and the screen frame is not larger than the mesh of the screen, and the screen is erected on the handle bar On one end, the area of the screen frame is 30cm×25cm, and the included angle between the holding rod and the plane where the screen frame is located is 45°. The mesh of the sieve can be circular, oval, rectangular or rhombus, etc. The sieve and the sieve frame are made of stainless steel or iron, so as to avoid the sampling pollution of the oil product by the dissolution of the organic material components.

[0038] Further, in this embodiment, the handle 1 is an aluminum alloy tube or a stainle...

Embodiment 2

[0055] This embodiment has been further improved on the basis of embodiment 1:

[0056] The optimum mesh aperture of the screen is 0.5mm, the screen frame is rectangular, and the area of the screen frame is 35cm×25cm. It not only improves the representativeness of collected samples, but also ensures the operability of the sampler.

Embodiment 3

[0058] This embodiment has been further improved on the basis of embodiment 1:

[0059] The optimum mesh aperture of the screen is 1.0mm, the screen frame is rectangular, and the area of the screen frame is 45cm×35cm. It not only improves the representativeness of collected samples, but also ensures the operability of the sampler.

[0060] In addition, the screen frame can also be square or circular, etc., to facilitate the calculation of the sampling area.

[0061] Using the sampling tool of the present invention to conduct experiments at the oil spill site of Penglai 19-3 oil field, the experiment proves that this method is effective in monitoring sea surface oil pollution (thicker oil film), and it is completely feasible to accurately monitor the thickness of surface oil pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com