Method for calibrating relation between rotating shaft and camera based on constraint global optimization

A calibration method and global optimization technology, applied in image data processing, instrumentation, computing, etc., can solve problems such as inability to directly collect images of calibration boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

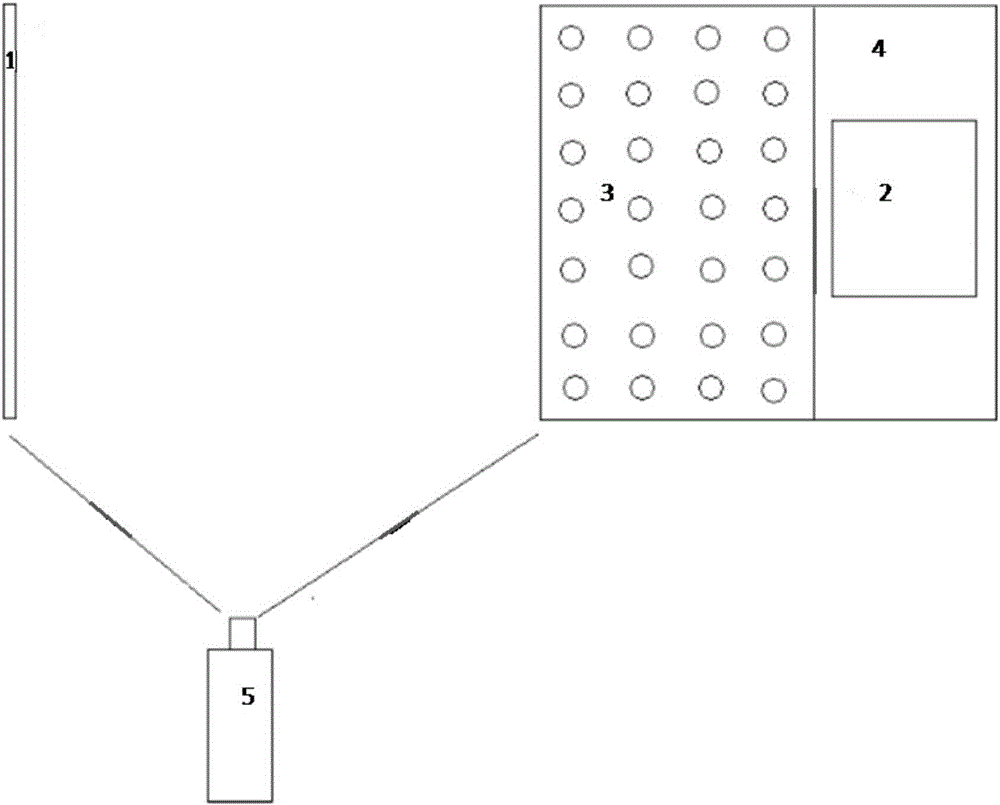

[0041] In this embodiment, a method for calibrating the relationship between the rotation axis and the camera based on constrained global optimization (hereinafter referred to as the calibration method) includes the following steps

[0042] 1) Use the turntable calibration plate 3 to calibrate the internal parameters of the large scene camera 5 and the camera 2 to be calibrated;

[0043] 2) When the rotating platform is at the starting position of the rotation, a picture of the calibration plate 1 is taken by the large scene camera and the camera respectively,

[0044] Starting from the starting position of the rotation, when the rotating shaft of the rotating platform rotates 360 degrees, the large scene camera rotates to 0°, 45°, 90°, 135°, 180°, 225°, 270°, and 315° in sequence. Take pictures of the calibration board 3 and get 8 series of pictures,

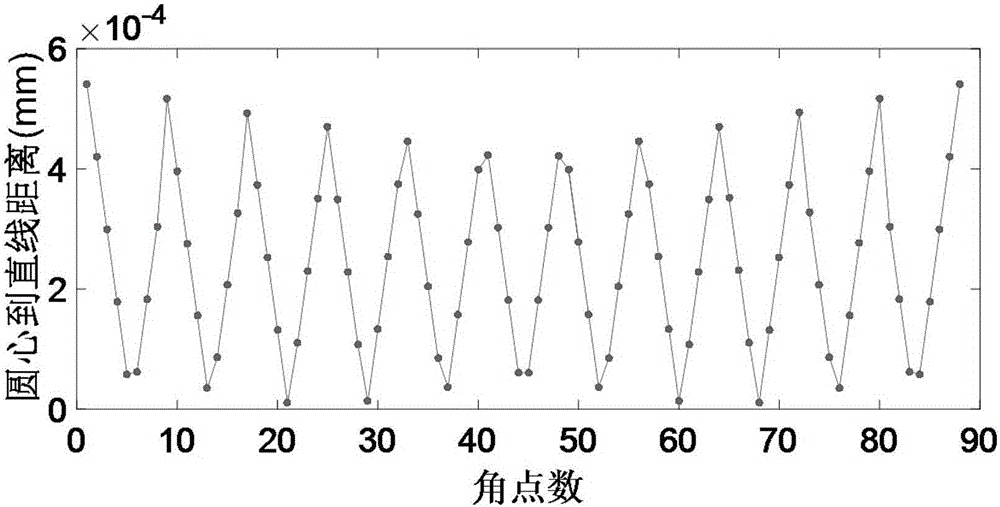

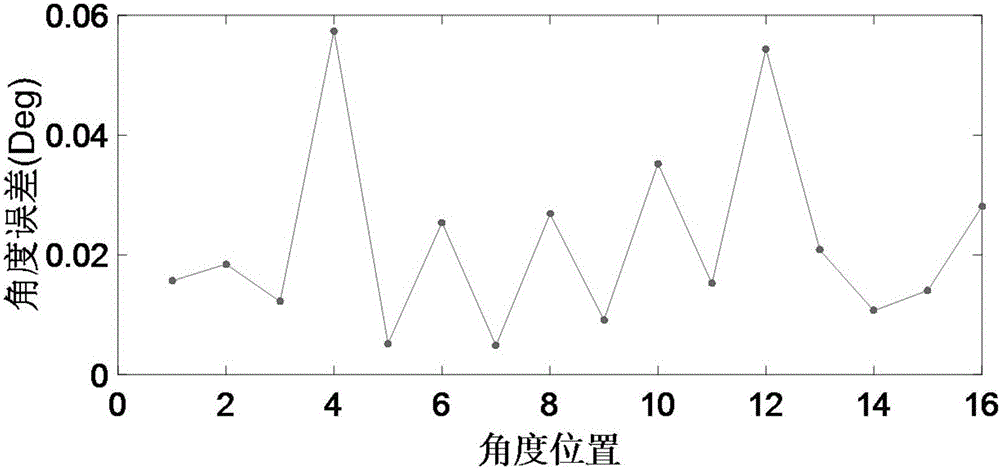

[0045] 3) The rotation matrix R of the calibration plate 1 to the large scene camera 5 coordinate system obtained from the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com