Slip-controllable vehicle brake system

A technology for vehicle braking and wheel braking, applied in the direction of brakes, ABS control systems, etc., can solve the problems of sharpening and reconstruction, and achieve the effect of compact structure and low starting current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

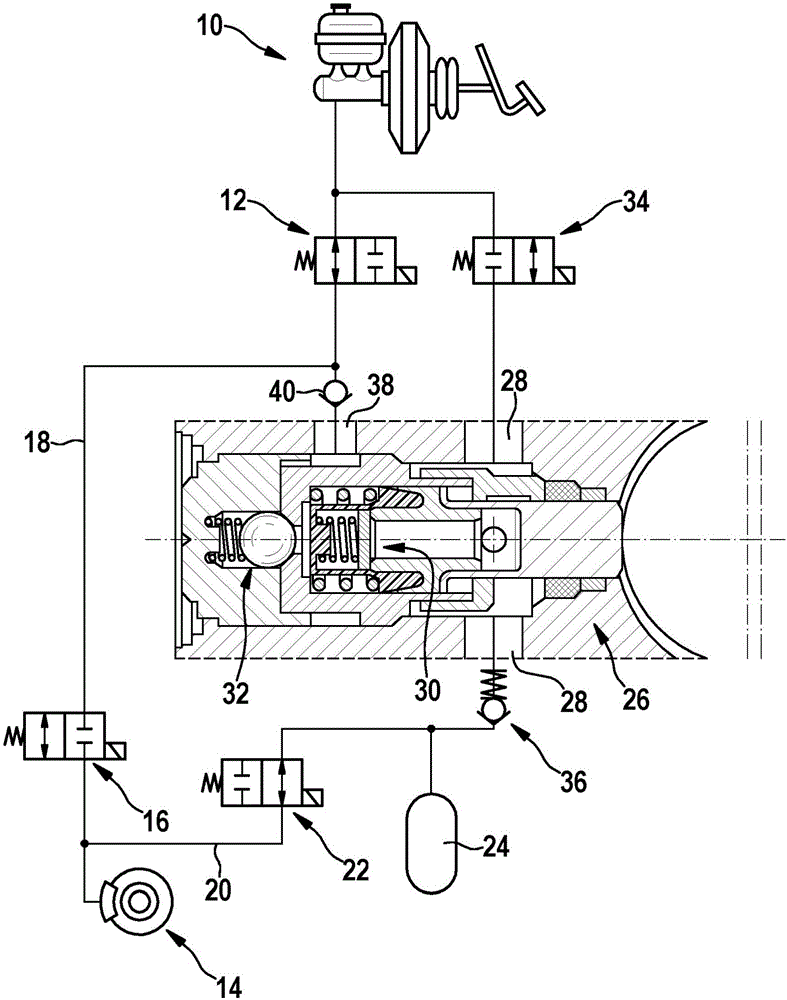

[0013] exist figure 1 The hydraulic connection diagram shown in shows the basically known brake circuit of a slip-adjustable vehicle brake system according to the connection symbols. The brake circuit also includes a master brake cylinder 10 which can be actuated by the driver by muscular force. The connection of the brake circuit to the main brake cylinder 10 is controllable via a switching valve 12 . In its basic position, the switchover valve 12 is open and can be switched to the off position by electromagnetic actuation. In the closed position of switchover valve 12 , it is not possible for the driver to vary the brake pressure at wheel brakes 14 connected to the brake circuit.

[0014] The brake circuit branches off downstream of the changeover valve 12 . A line branch leads via a pressure generating valve 16 in the form of a normally open 2 / 2 switching valve to the wheel brake 14 and thus forms its inflow 18 .

[0015] The return 20 branches off from the inflow 18 di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com