High-efficiency condensing device for water reducer

A technology of condensing device and water reducer, which is applied in the fields of filtration separation, chemical/physical/physicochemical fixed reactor, lighting and heating equipment, etc. It can solve the problems of lack of filtering function, poor cooling effect, inconvenient use, etc. problem, to achieve the effect of simple structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to have a further understanding and understanding of the structural features of the present invention and the effects achieved, the preferred embodiments and accompanying drawings are used in conjunction with detailed descriptions, and the descriptions are as follows:

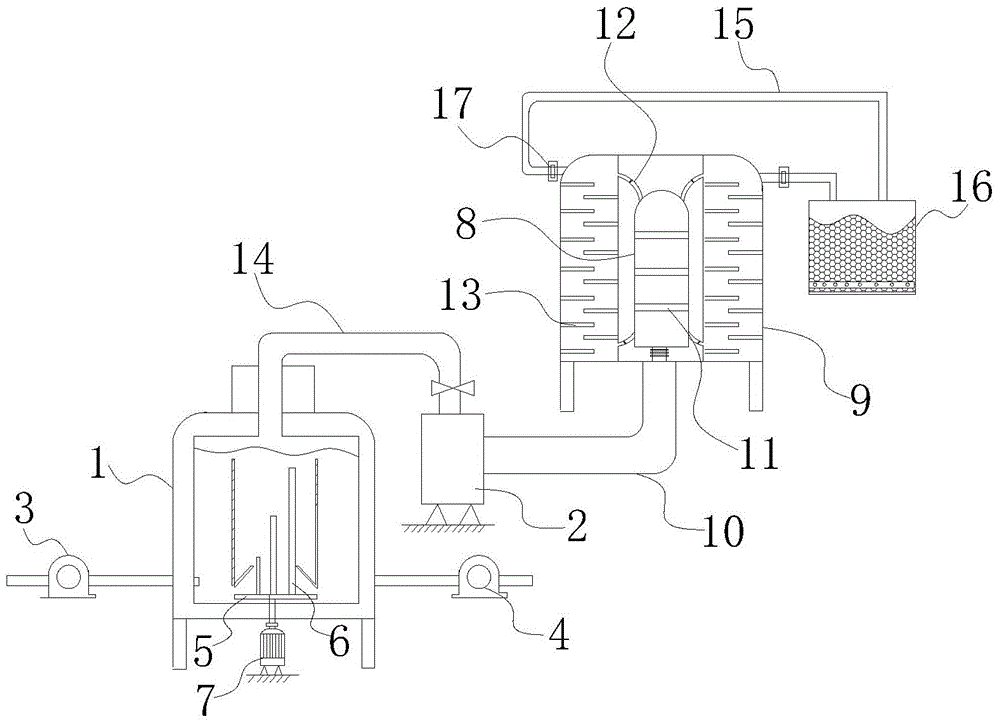

[0014] like figure 1 As shown, a high-efficiency condensing device of a water-reducing agent comprises a reactor 1, a storage tank 2 connected with the reactor 1 and a cooling device connected with the storage tank 2, and a filter device is also provided on one side of the cooling device ;

[0015] The two sides of the reaction kettle 1 are respectively provided with a feed pump 3 and a discharge pump 4, the bottom of the reaction kettle 1 is provided with a rotating disk 5, and a plurality of vertical stirring rods 6 are arranged on the rotating disk 5. The rotary motor 7 at the bottom of the reactor 1 is connected;

[0016] The cooling device includes a cooling tank. The cooling tank is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com