Frame type base frame of spray-painting equipment

A spraying equipment and frame-type technology, applied in the field of frame-type base frame, can solve the problems of complex surface and many curved surfaces, poor processing quality, short stroke, etc., and achieve the effects of beautiful structure, improved quality and precision, and enhanced rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

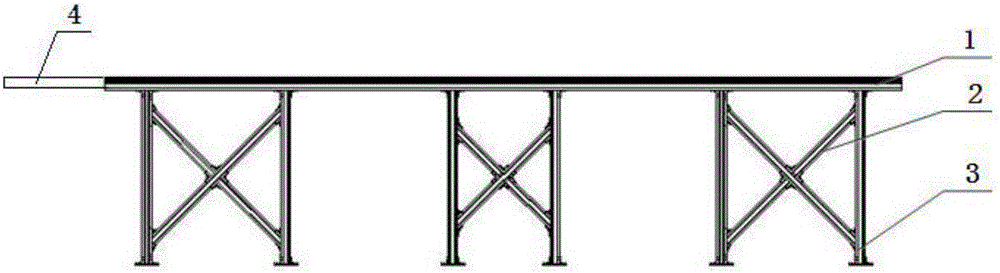

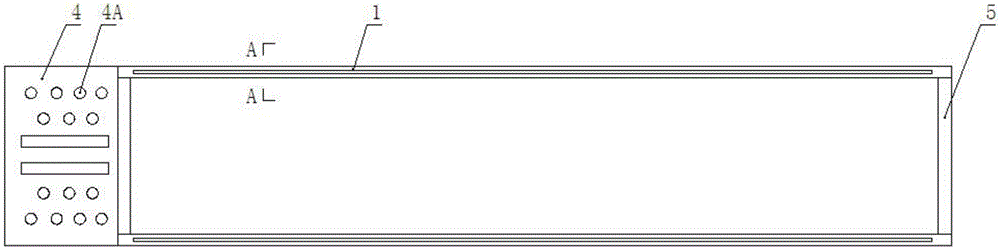

[0020] A frame-type base frame for spraying equipment, such as figure 1 , 2 As shown, it includes a crossbeam 1, a longitudinal beam 5 and a support leg 3. The crossbeams are two, and the horizontal beams are symmetrically arranged in parallel and spaced apart. A plurality of sets of legs, one side of the longitudinal beam is fixed with a storage plate 4 for storing tools and nozzles, and the end surface of the storage plate is formed with a groove 4A for placing tools.

[0021] In this embodiment, in order to improve the stability performance, X-shaped reinforcing ribs 2 are installed between each group of outriggers.

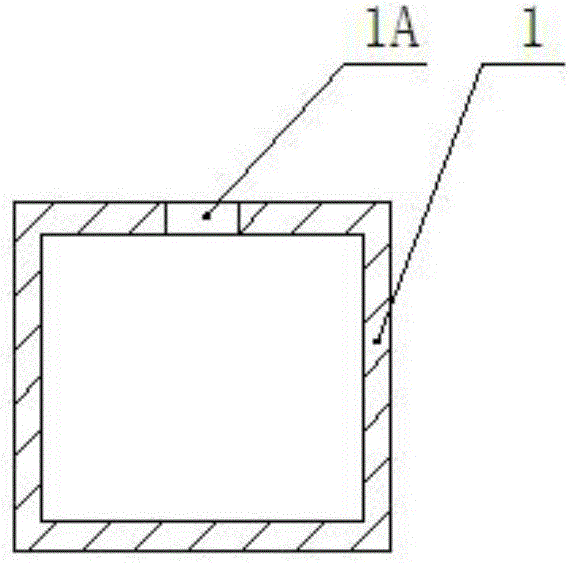

[0022] The beams, longitudinal beams and supporting legs are all made of aluminum profiles, which greatly enhances the rigidity of the structure, can be applied in medium and low load occasions, has a beauti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com