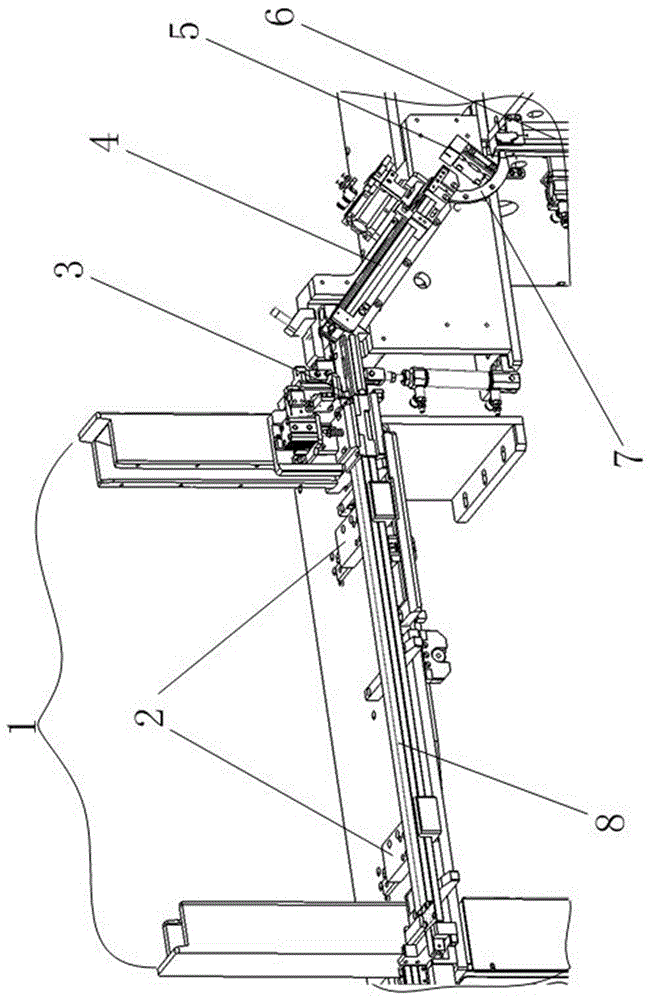

Straight back type test-sorting machine feeding and conveying device for integrated circuit chips

A technology for testing sorting machines and integrated circuits, applied to mechanical conveyors, sorting, conveyors, etc., can solve the problems of large chip posture changes, large space required for material tubes, and error-prone, etc., to achieve easy comparison and The effect of practical test and simplification of chip comparison work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

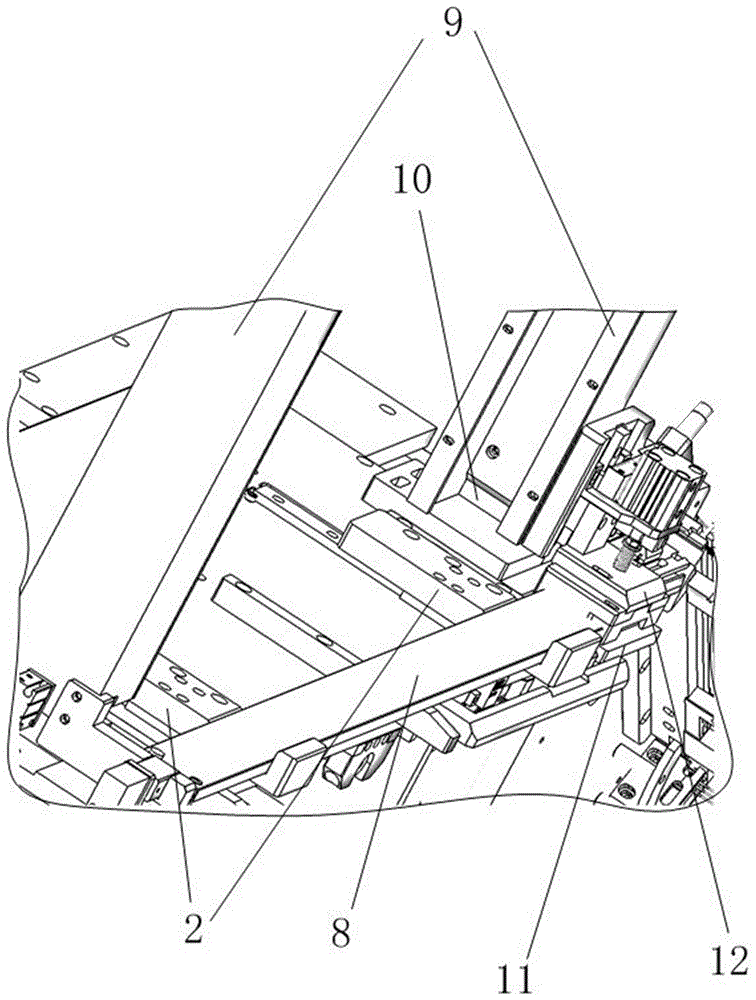

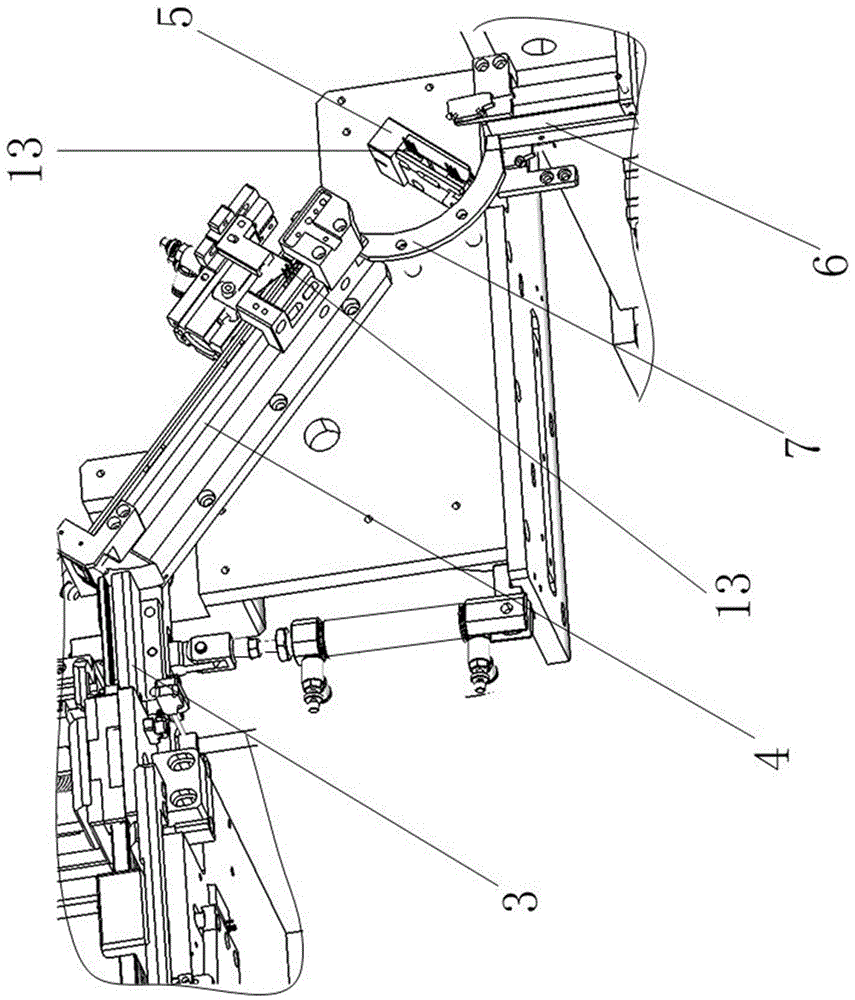

[0042] The operator opens one end of the material tube, stacks the material tubes in the storage mechanism, and makes the open end of the material tube on the same side of the storage mechanism, and the kick tube dislocation device removes the material at the bottom of the material tube slide The top of the material tube reaches the concave part so that the material tube and other material tubes are staggered, and the industrial computer controls the pushing mechanism 2 to move to the concave part 10 to accept the material tube; the pushing mechanism 2 sends the material tube to the lifting tube At the turning mechanism; when the lifting and turning mechanism 3 receives the material material tube 8, the material tube mouth of the material material tube 8 is docked with the first slideway of the chip, and then the lifting tube turning mechanism 3 is turned over to make the first slideway of the chip and the middle inclined track 4 are connected, the chip 13 in the material mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com