Electrostatic powder spraying repair method based on three-dimensional modeling

A technology of electrostatic powder and repair method, which is applied in the direction of coating, liquid coating device on the surface, special surface, etc., can solve problems such as shedding, rough working surface, unevenness, etc., and achieve reliable work, ensure reliability and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

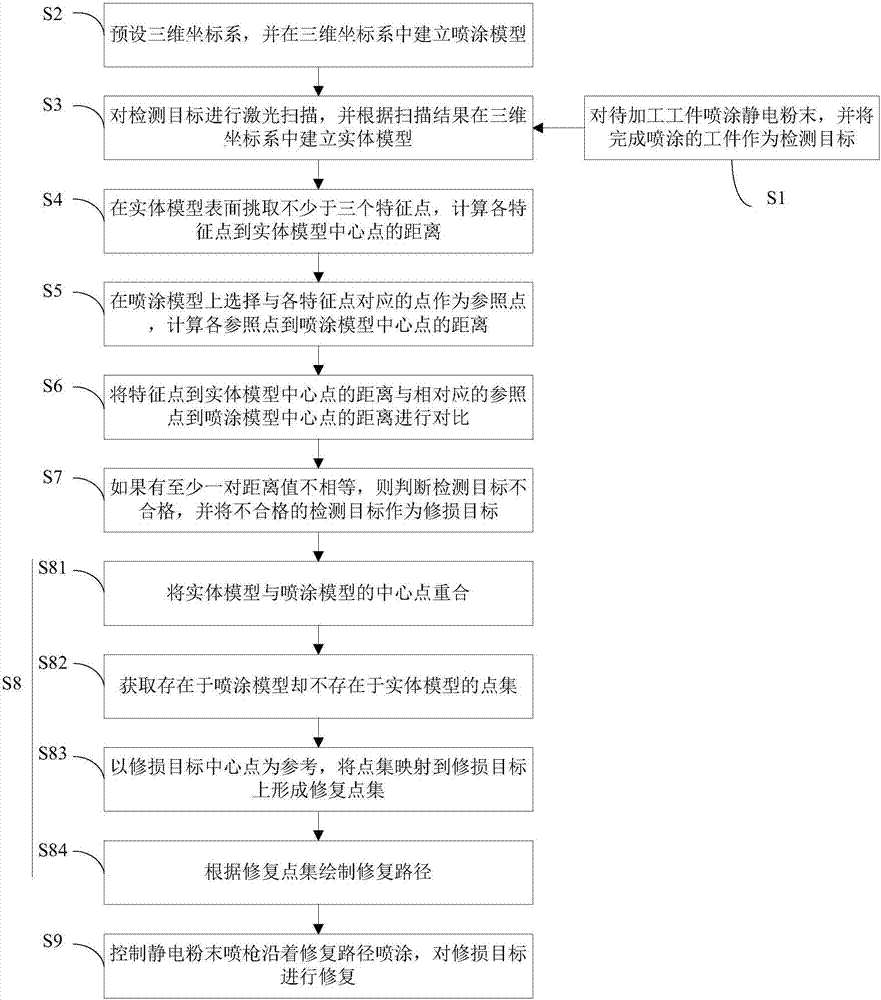

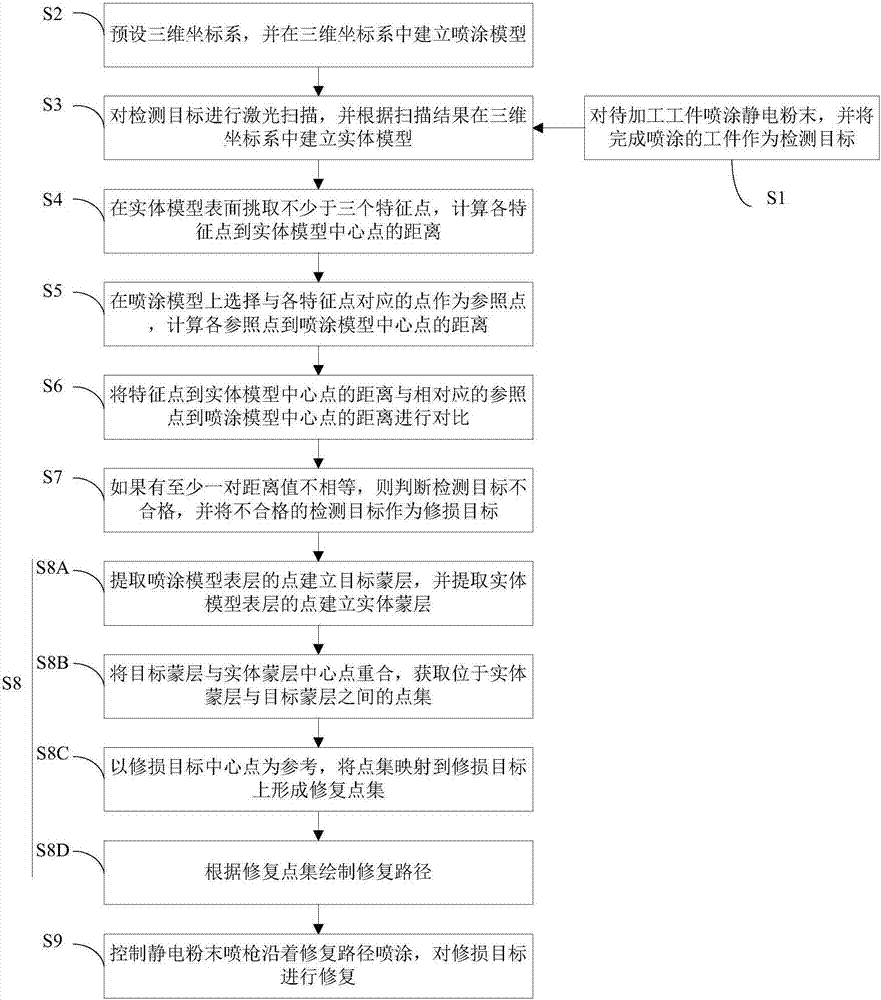

[0031] refer to figure 1 , an electrostatic powder spraying repair method based on three-dimensional modeling proposed by the present invention includes the following steps.

[0032] S1. Spray electrostatic powder on the workpiece to be processed, and take the sprayed workpiece as the detection target. In this step, the overall spraying of the workpiece is mainly carried out.

[0033] S2. Presetting a three-dimensional coordinate system, and establishing a spraying model in the three-dimensional coordinate system. The establishment of the spraying model lays the foundation for the detection of detection targets and the repair of unqualified workpieces.

[0034] S3. Laser scanning is performed on the detection target, and a solid model is established in a three-dimensional coordinate system according to the scanning result. Specifically, in this step, laser scanning is performed on the detection target by infrared rays to ensure scanning efficiency and accuracy.

[0035] S4...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is that this embodiment replaces steps S8A, S8B, S8C and S8D respectively, and S81, S82, S83 and S84 in embodiment 1; In different ways, the repair target is compared with the spray model, and the repair path is drawn according to the comparison result.

[0050] Specifically, in this embodiment, the method of comparing the repair target with the spray model, and drawing the repair path according to the comparison result specifically includes the following steps.

[0051] S8A. Extract points on the surface of the sprayed model to establish a target mask, and extract points on the surface of the solid model to establish a solid mask.

[0052] S8B. The center points of the object mask and the entity mask are overlapped to obtain a point set between the entity mask and the object mask.

[0053] S8C. Using the center point of the damaged target as a reference, map the point set to the damaged target to form a repaired ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com