Intelligent repair powder spraying equipment

A spraying equipment and intelligent repair technology, applied in the direction of liquid spraying equipment, etc., can solve problems such as heavy workload, difficulty in ensuring spraying quality, and difficulty in controlling labor costs, so as to ensure reliability and stability, avoid workers' health damage, and solve problems The effect of unreliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

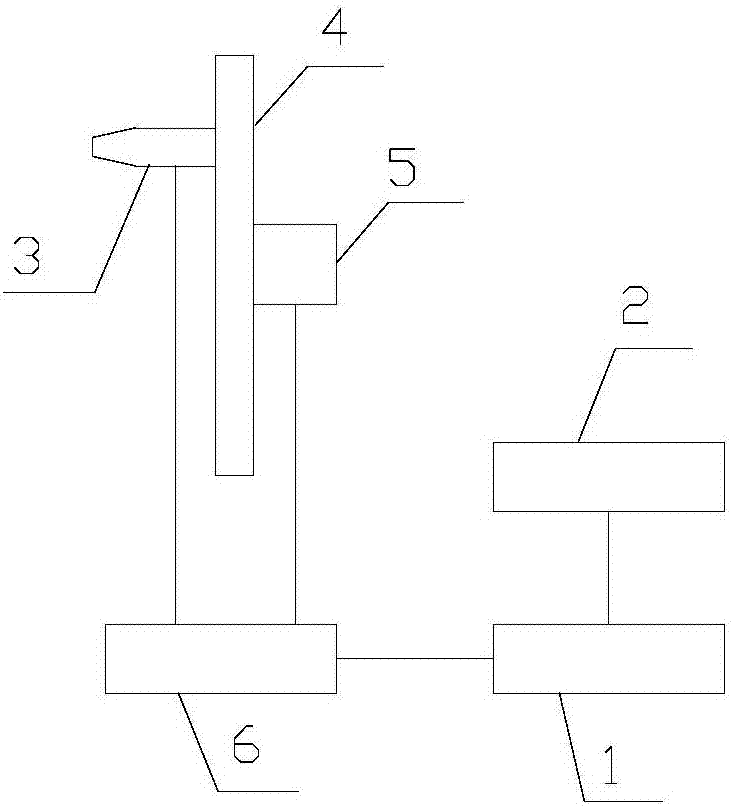

[0024] refer to figure 1 , an intelligent repair powder spraying equipment proposed by the present invention, including: a modeling unit 1, a scanning unit 2, an electrostatic powder spray gun 3, a spray gun support frame 4, a spray gun driving mechanism 5 and a control processing unit 6.

[0025] A three-dimensional coordinate system is set in the modeling unit 1, and a spraying model is preset in the three-dimensional coordinate system.

[0026] The scanning unit 2 is connected with the modeling unit 1 and is used for scanning the restoration target. In this embodiment, the scanning unit 2 uses an infrared laser for scanning, and the infrared scanning method can ensure scanning efficiency and accuracy.

[0027] The modeling unit 1 establishes a solid model based on the scanning data in the three-dimensional coordinate system, compares the solid model with the sprayed model, and generates a missing model according to the comparison result, and the missing model includes all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com