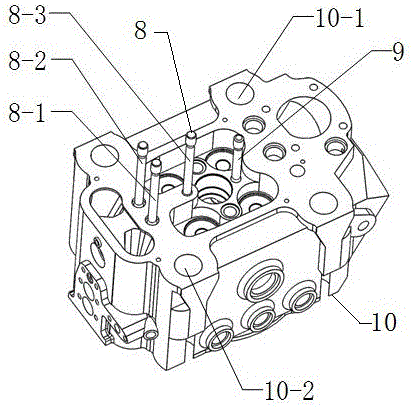

Automatic assembling machine for mounting studs of cylinder cover of diesel engine and assembling method

A cylinder head and assembly machine technology, applied to assembly machines, metal processing, metal processing equipment, etc., can solve the problems of low assembly accuracy and backward assembly technology, and achieve the effects of high practicability, high degree of automation, and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

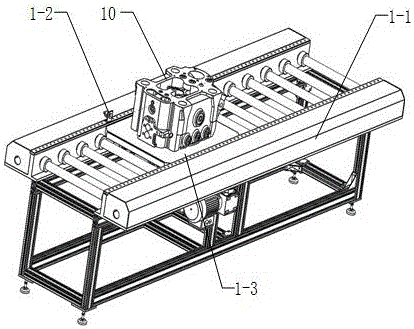

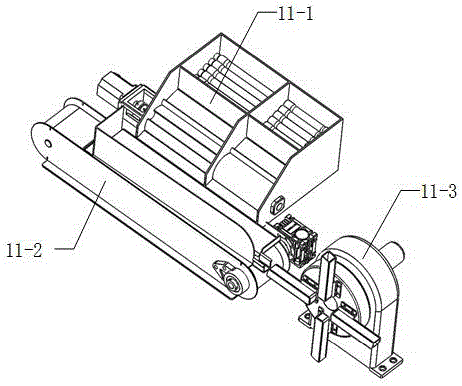

[0036] refer to figure 2 Shown: an automatic assembly machine for installing diesel engine cylinder head studs in the present invention mainly includes a transmission device 1, a tooling table 2, an automatic material screening mechanism 11, an automatic feeding mechanism 22 and an automatic tightening mechanism 31. The transmission device 1 is installed on the ground in a forward and backward transmission state, and is installed horizontally parallel to the ground. The cylinder head 10 is placed on the transmission device 1, and the transmission device 1 can transmit the cylinder head 10 back and forth; the position directly above the transmission device 1 is automatically tightened. agency31. On the left side of the conveying device 1 is a tooling platform 2, which is installed on the ground, and an automatic screening mechanism 11 and an automatic feeding mechanism 22 are fixedly arranged above the table top of the tooling platform 2, and the automatic feeding mechanism 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com