Electric box carrying mechanical hand

A technology of manipulators and boxes, applied in the direction of manipulators, chucks, manufacturing tools, etc., to achieve the effect of simple structure, compact overall structure, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

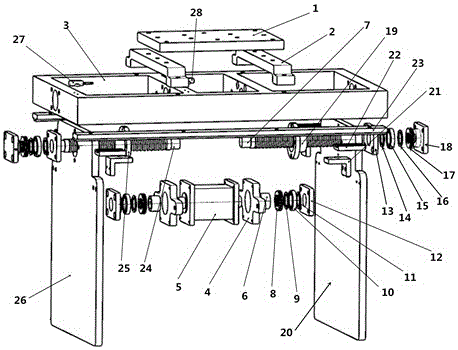

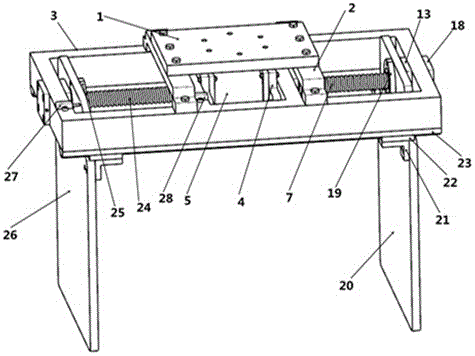

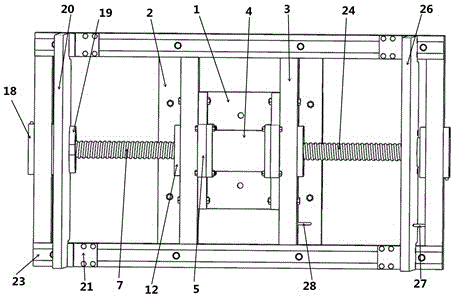

[0020] Structural principle of the present invention is described in detail below in conjunction with accompanying drawing:

[0021] The electric box handling manipulator includes a fixed plate 1 connected to the end of the robot, a fixed support 2 installed under the fixed plate 1, a base 3 installed under the fixed support 2; a motor fixed seat installed inside the truss of the base 3 4. The double output shaft stepping motor 5 installed on the motor fixing seat 4, the double output shaft stepping motor 5 is connected with the ball screw 7 through the coupling 6, and the plane thrust bearing 8 is installed in the mounting hole of the base 3 , the plane thrust bearing 8 is installed on one end of the ball screw 7 through the bearing gasket 9 and the deep groove ball bearing 10, and the deep groove ball bearing 10 is installed on the base 3 together with the bearing end cover 12 through the bearing gasket 11; the bearing The end cover 13 is installed on the inner side of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com