Quick paper breaking re-winder

A rewinding machine and paper cutting technology, which is applied in metal processing and other directions, can solve the problems of toilet paper not being able to guarantee smoothness and low efficiency, and achieve the effect of conveniently fixing the stick shaft, high efficiency of work, and smooth paper roll

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

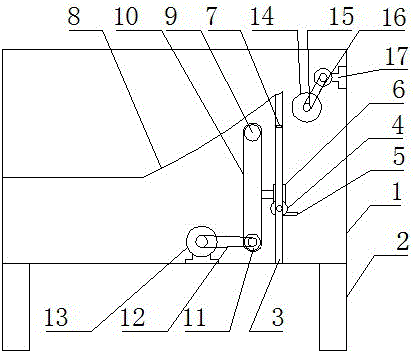

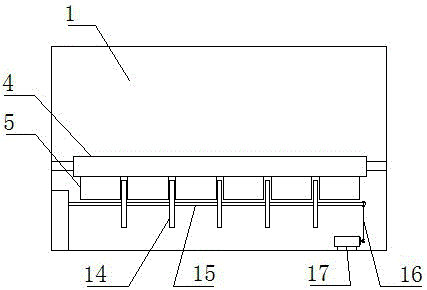

[0016] Such as figure 1 and figure 2 Shown, a kind of rapid paper break rewinding machine, it comprises frame 1, and the bottom of described frame 1 is equipped with support leg 2, and the right side of the top of described frame 1 is equipped with fixed plate 3, so The inner side of the fixed plate 3 is equipped with a stick shaft 4, the outside of the described stick shaft 4 is provided with a cardboard 5, the top of the described stick shaft 4 is connected with a connecting block 6, and the upper part of the fixed plate 3 is A distance sensor 7 is arranged on the outside, a slope surface 8 is connected to the top of the fixed plate 3, and a driven shaft 9 is arranged below the slope surface 8, and the driven shaft 9 is connected to the The driving shaft 11, the driving shaft 11 is connected with the transmission motor 13 through the main conveyor belt 12, the top right of the fixed plate 3 is provided with a cutting knife 14, and the cutting knife 14 is connected with the...

Embodiment 2

[0019] Such as figure 1 and figure 2 Shown, a kind of rapid paper break rewinding machine, it comprises frame 1, and the bottom of described frame 1 is equipped with support leg 2, and the right side of the top of described frame 1 is equipped with fixed plate 3, so The inner side of the fixed plate 3 is equipped with a stick shaft 4, the outside of the described stick shaft 4 is provided with a cardboard 5, the top of the described stick shaft 4 is connected with a connecting block 6, and the upper part of the fixed plate 3 is A distance sensor 7 is arranged on the outside, a slope surface 8 is connected to the top of the fixed plate 3, and a driven shaft 9 is arranged below the slope surface 8, and the driven shaft 9 is connected to the The driving shaft 11, the driving shaft 11 is connected with the transmission motor 13 through the main conveyor belt 12, the top right of the fixed plate 3 is provided with a cutting knife 14, and the cutting knife 14 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com