Movable gantry type rotary automatic balance weight truck-mounted self-handling equipment

A gantry-type, self-loading and unloading technology, applied in the mechanical field, can solve problems such as inapplicability in narrow places, safety accidents, space occupied by jacking devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

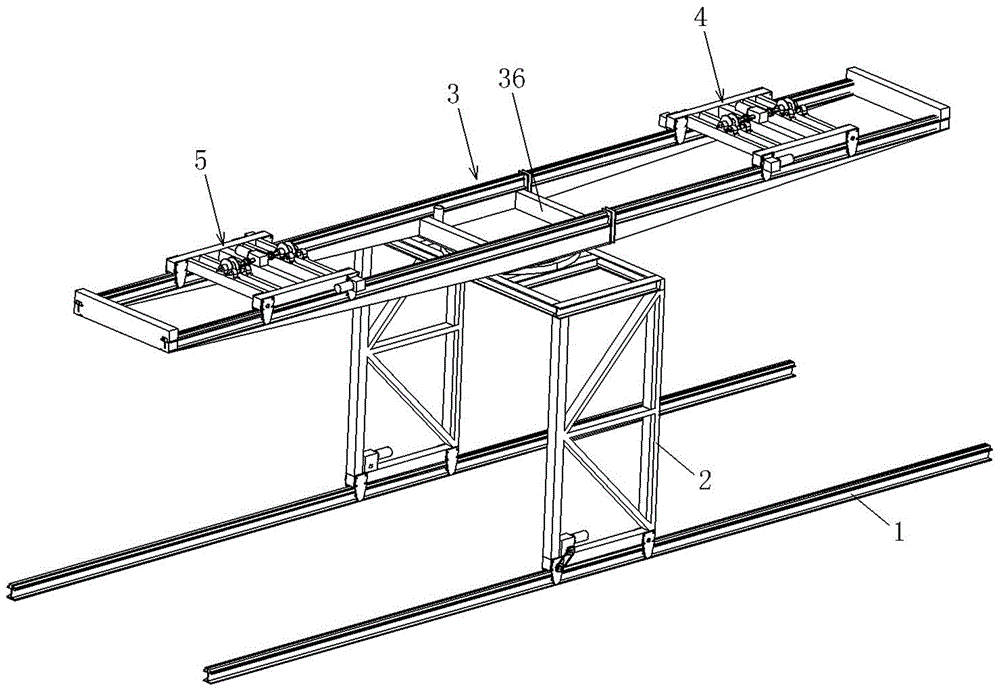

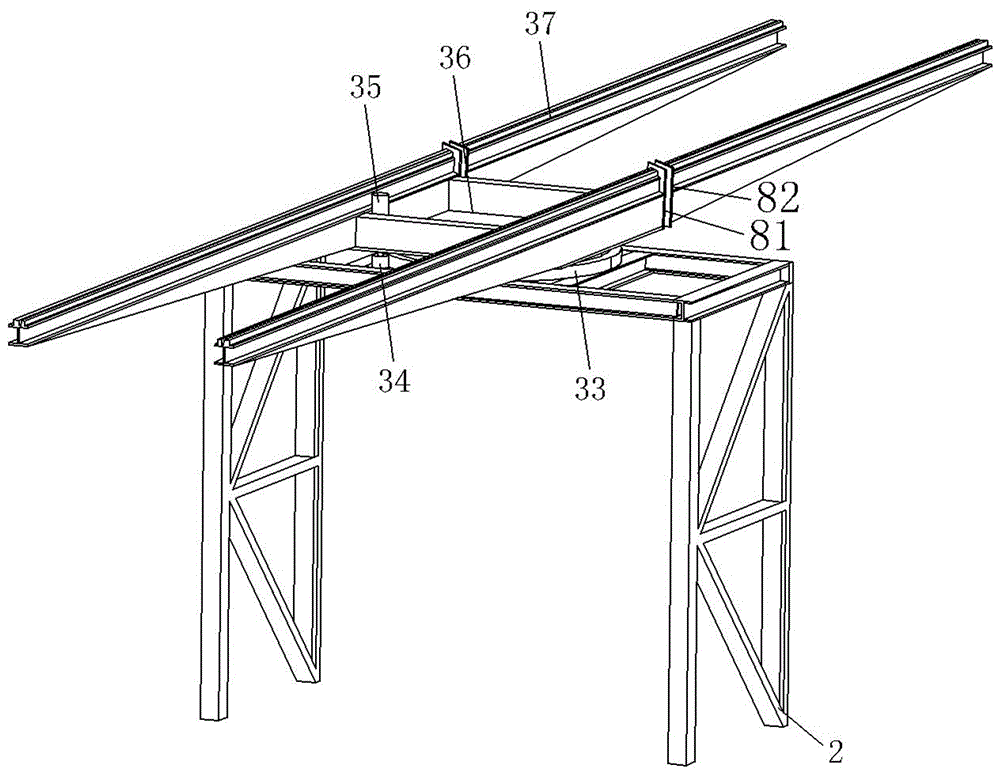

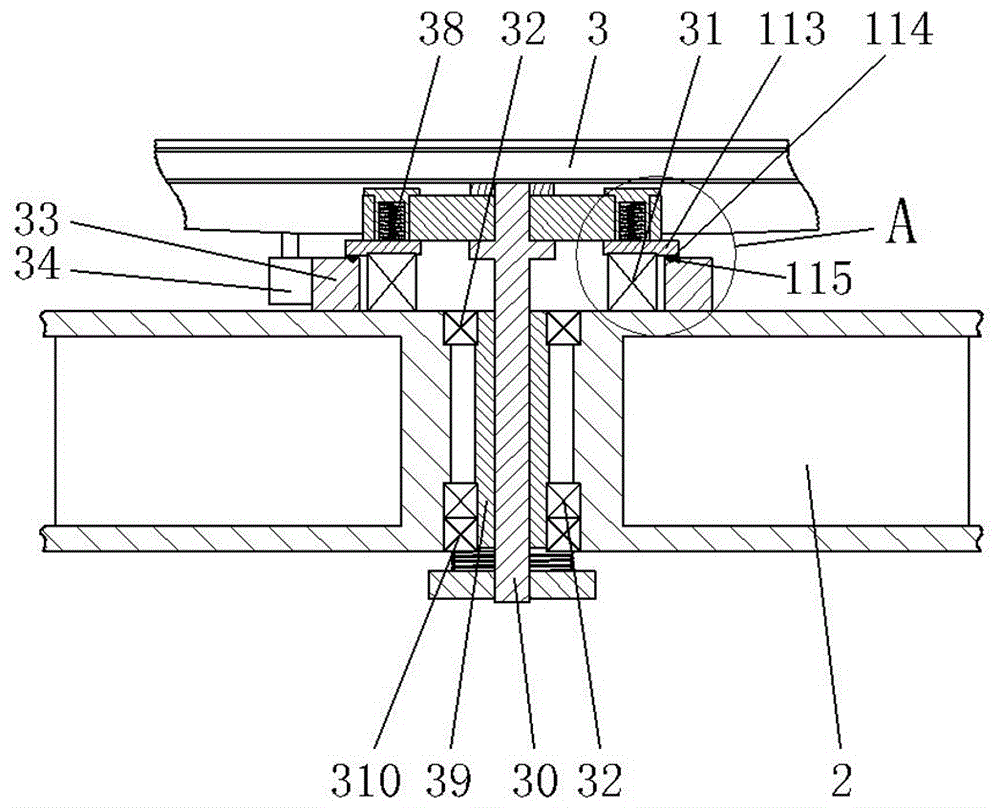

[0056] Such as figure 1 The shown mobile gantry type, rotatable automatic counterweight vehicle-mounted self-loading and unloading equipment includes two guide rails 1 arranged parallel to each other and a gantry mobile frame 2 straddling the two guide rails 1 , between the mobile frame 2 and the guide rail 1 . A drive unit 1 for driving the moving frame 2 to move along the guide rail 1 is arranged between them. Such as figure 1 and figure 2 As shown, the top of the mobile frame 2 is provided with a pole-type rotary frame 3, and one end of the rotary frame 3 is provided with a mobile seat 4 that can move along the rotary frame 3. Grabbing structure, the other end of the rotating frame 3 is provided with a counterweight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com