Organic fiber PVC (Polyvinyl Chloride) multilayered composite flexible pipe and preparation method thereof

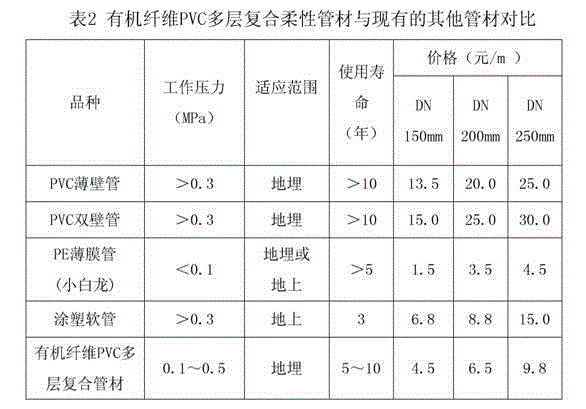

A composite flexible and organic fiber technology, applied in the production field of agricultural irrigation pipes, can solve the problems of crack resistance, poor frost resistance, poor toughness and tensile strength, poor corrosion resistance, etc., to achieve smooth inner wall of the pipe, tensile strength Good performance, good wrinkle resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

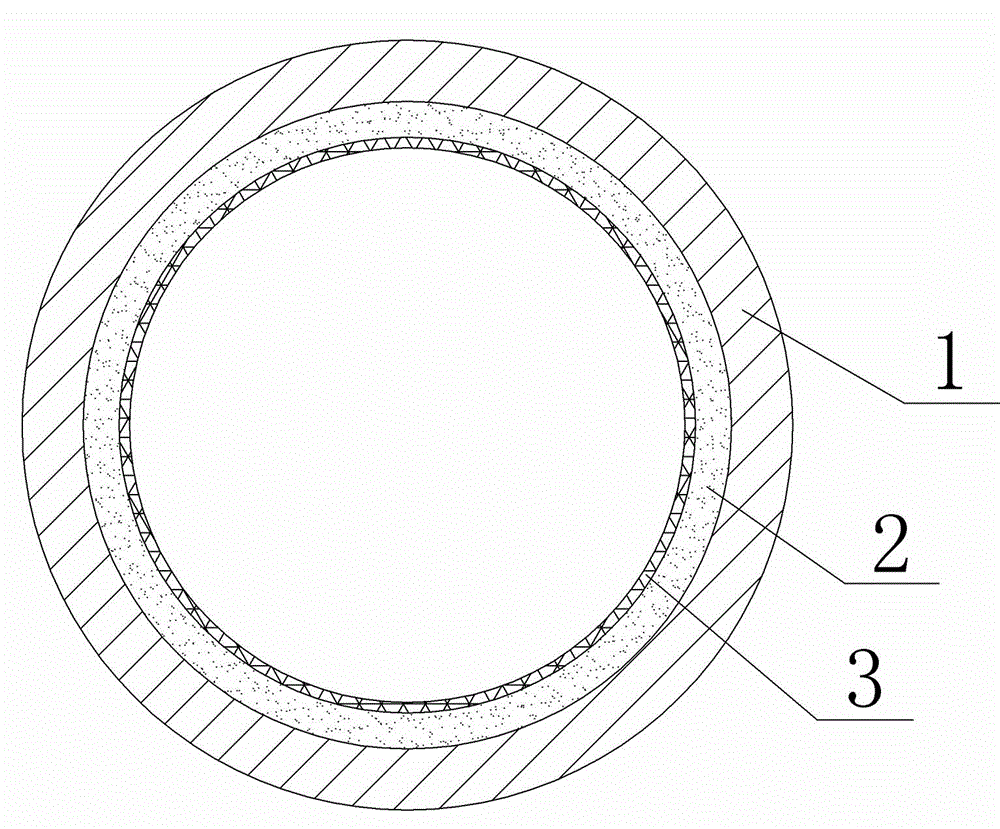

[0026] Embodiment 1: An organic fiber PVC multilayer composite flexible pipe, comprising a pipe body 1, a polyvinyl chloride plastic coating layer 2 is provided on the inner wall of the pipe body 1, and a composite plastic film layer 3 is provided on the plastic coating layer 2; The pipe body 1 is made of the following raw materials in parts by weight: 30 parts of polyacrylonitrile fiber, 10 parts of liquid silica gel, and 5 parts of liquid PVC stabilizer.

[0027] Among them, according to the different diameters of the pipes, the thickness of the pipe body 1 is between 0.3 and 0.5mm; the thickness of the plastic coating layer 2 is between 0.1 and 0.5mm; the liquid PVC stabilizer is a liquid barium-zinc composite stabilizer; the composite plastic The film layer is a PE plastic film cured on the plastic coating layer.

Embodiment 2

[0028] Example 2: An organic fiber PVC multilayer composite flexible pipe, the difference from Example 1 is that the parts by weight of the raw materials in the pipe body are: 28 parts of polyacrylonitrile fiber, 11 parts of liquid silica gel, liquid 7 parts of PVC stabilizer, the liquid PVC stabilizer is a liquid calcium-zinc composite stabilizer.

Embodiment 3

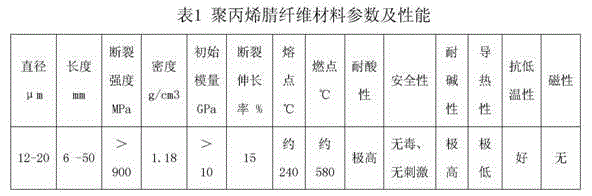

[0029] Embodiment 3: An organic fiber PVC multilayer composite flexible pipe. The difference from Embodiment 1 is that the parts by weight of the raw materials in the pipe body are: 33 parts of polypropylene fiber, 9 parts of liquid silica gel, and 9 parts of liquid silica gel. 4 parts of PVC stabilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com