Opening labeling machine and cigarette packaging production system

A labeling machine and production line technology, which is applied in the field of tobacco packaging, can solve the problems of damaging the sealing strip of cigarette labels, affecting the taste and quality, and being cumbersome, and achieves the effects of ingenious structural design, favorable promotion and application, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

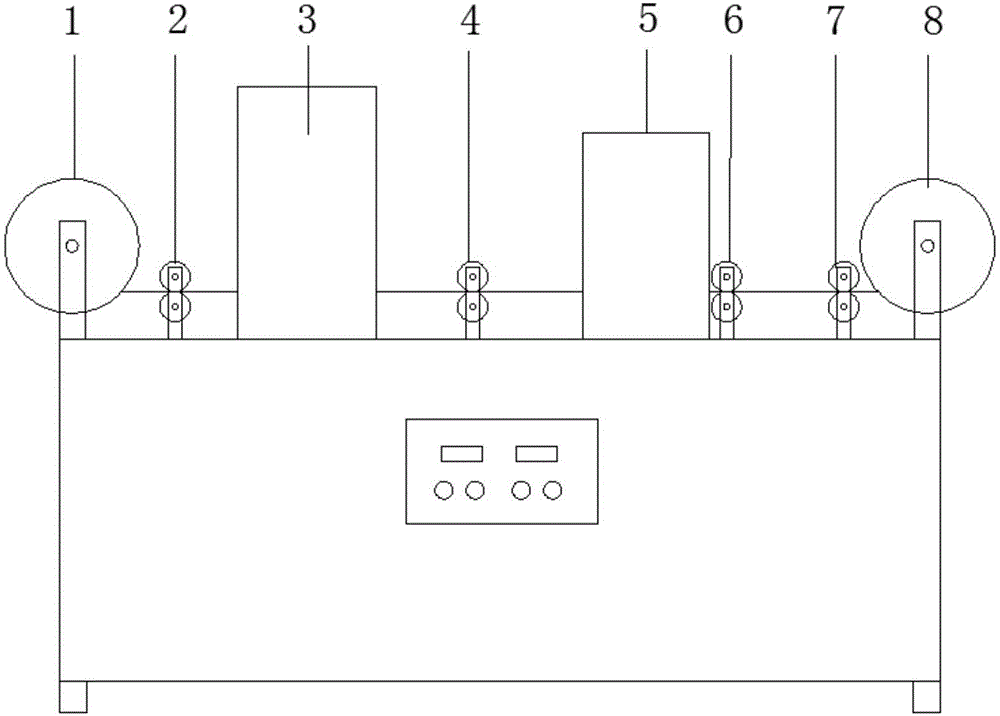

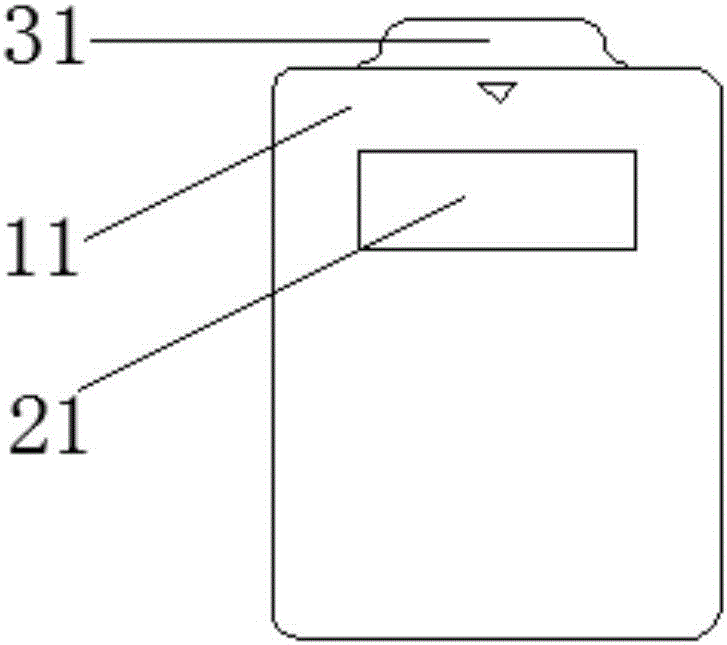

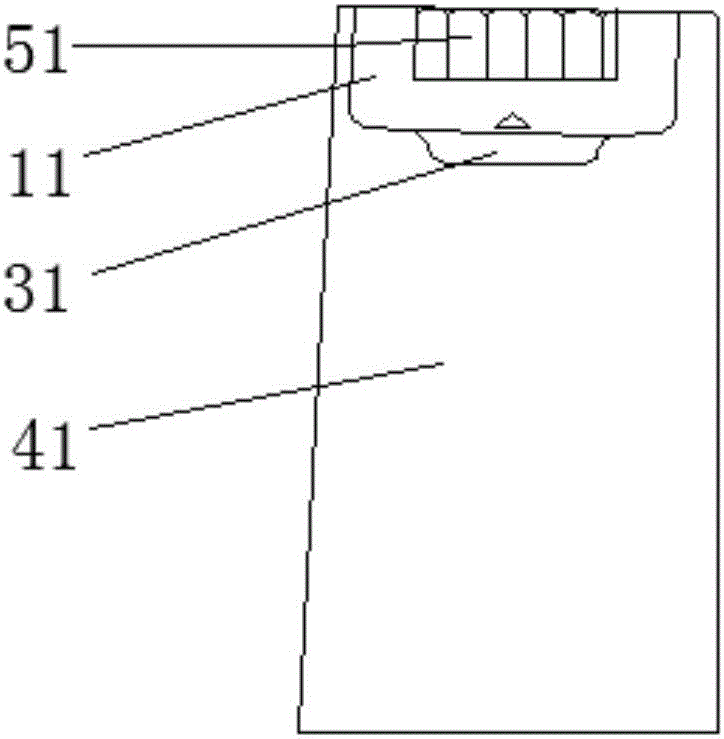

[0036] combine Figure 1 to Figure 4 As shown, the present embodiment one provides a kind of opening labeling machine 5, and it comprises the feeding mechanism that is arranged in sequence along the production line, die-cutting machine 3, labeling machine 5 and material receiving mechanism; Feeding mechanism is positioned at the initial end of this production line , used to transfer the lining paper to be processed to the die-cutting machine 3 along the conveying path; In order to complete the cutting action inside, the discharge port of the die-cutting machine 3 is set on the side away from the feeding mechanism, which is used to discharge the cut inner lining paper from the die-cutting machine 3; the feed port of the labeling machine 5 is set on the side close to the die One side of the outlet of the cutting machine 3 is used to make the cut inner lining paper enter the inside of the labeling machine 5 to bond the labeling parts at intervals. The labeling parts are provided ...

Embodiment 2

[0065] combine Figure 1 to Figure 4 As shown, the second embodiment provides a cigarette packaging production system, which includes a tobacco packaging machine 9 and an opening labeling machine 5 connected to the tobacco packaging machine 9 .

[0066] The open labeling machine 5 includes a feeding mechanism, a die-cutting machine 3, a labeling machine 5 and a material receiving mechanism arranged in sequence along the production line; The conveying path is sent to the die-cutting machine 3; the feed port of the die-cutting machine 3 is set on the side close to the feeding mechanism, which is used to make the inner lining paper enter the inside of the die-cutting machine 3 to complete the cutting action, and the die-cutting machine 3 The discharge port is arranged on the side away from the feeding mechanism, and is used to discharge the cut inner lining paper from the die-cutting machine 3; In order to make the cut inner lining paper enter the interior of the labeling machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com