A fluidized anti-blocking discharge valve

An unloading valve and anti-blocking technology, applied in the field of unloading valve, can solve the problems of poor discharge of powder and ash, and achieve the effects of smooth unloading, convenient installation and maintenance, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

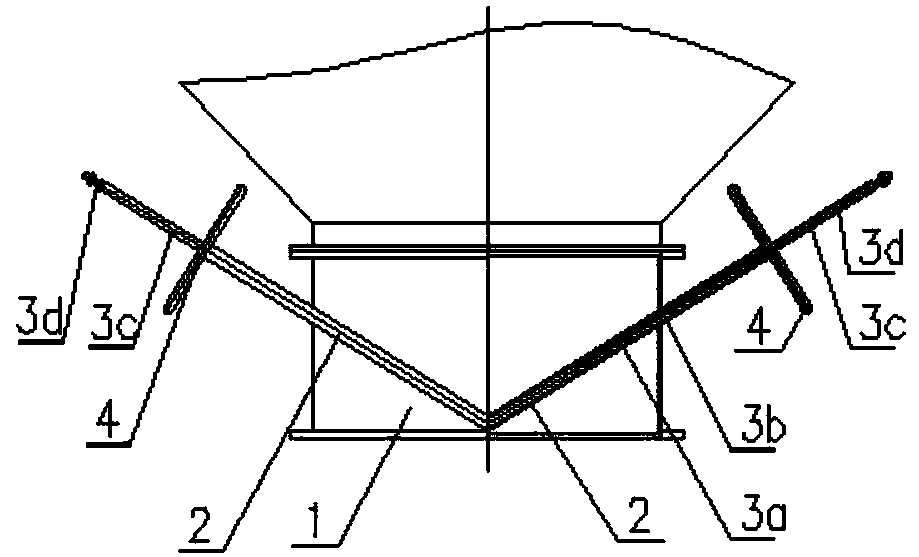

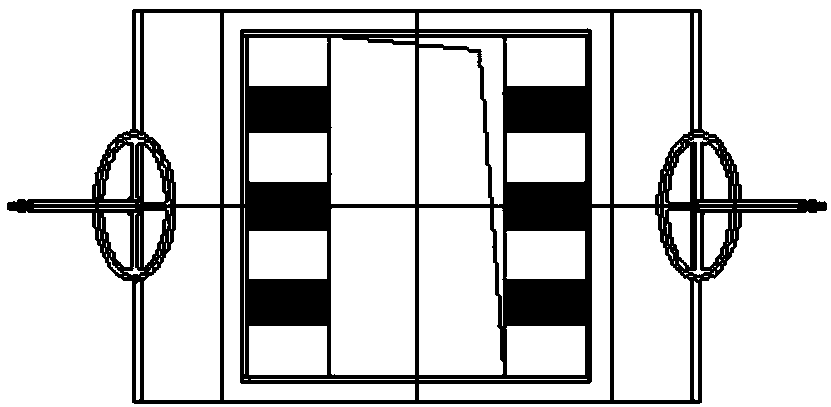

[0023] like figure 1 and figure 2 As shown, a fluidized anti-blocking discharge valve of this embodiment includes a valve body 1, a valve plate slot 2, a valve plate 3a, a fluidized plate 3b, a valve plate pulling rod 3c, a valve plate inflation pipe 3d and Hand wheel 4, the above-mentioned valve body 1 is provided with a feed port, the above-mentioned valve plate pulling rod 3c is provided with a valve plate inflation pipe 3d, the length of the valve plate pulling rod 3c is 8-15cm, and the above-mentioned fluidized plate 3b Embedded in the valve plate 3a, the valve plate 3a is set in the valve plate slot 2, the cross section of the valve plate slot 2 is circular, the material of the valve plate 3a is iron or aluminum, the fluidized plate 3b and the valve plate pulling rod 3c, the above-mentioned handwheel 4 is set between the fluidized plate 3b and the valve plate pulling rod 3c, and the handwheel 4 is an electric worm gear mechanism.

[0024] When the feed port of the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com