Logistics robot

A logistics robot and linear technology, applied in the field of logistics and warehousing, can solve problems such as cargo falling, cargo swing, safety accidents, etc., to achieve the effect of avoiding safety accidents, increasing the stability of rising, and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

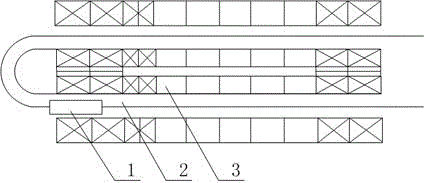

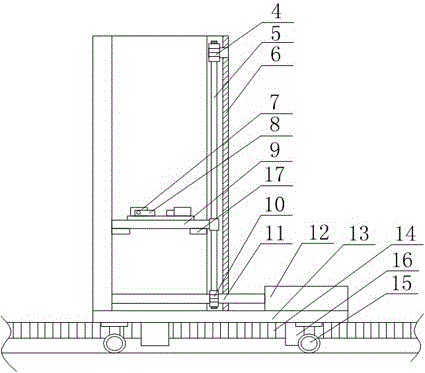

[0020] like figure 1 and figure 2 As shown, the present embodiment includes a guide aisle 2 and a stacking mechanism 1 cooperating with it. The guide aisle 2 includes a straight aisle installed between adjacent shelves 3 and a semicircular transition aisle connecting adjacent straight aisles. The aisles are smoothly spliced and fixed by connectors. Continuous protrusions 14 are provided on the straight aisles and transitional aisles. The stacking mechanism 1 includes support plates 13 placed on the protrusions 14. The bottom is equipped with a plurality of rollers 15 located on both sides of the protrusion 14, and a clamp 16 clamped with the side wall of the protrusion 14 is installed on the side wall of the support plate 13, and the support plate 13 is provided with a motor 12 and two columns 6, There is a rectangular groove on the side walls of the two columns 6 opposite to each other. The output end of the motor 12 is connected with a connecting rod 11. The connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com