Compound fertilizer for increasing sugarcane yield and preparation method thereof

A technology of compound fertilizer and production method, which is applied in the field of agricultural chemical fertilizers, can solve the problems of soil nutrient loss, lack of bactericidal effect, and inability to ensure nutrient supply, etc., to improve soil structure and quality, and the production process is convenient and simple. The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

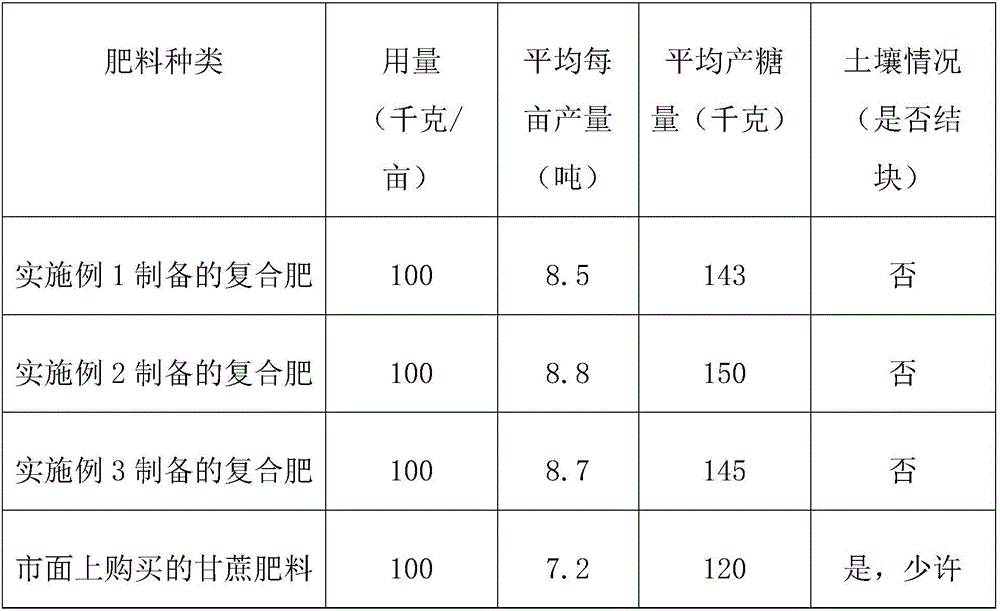

Examples

preparation example Construction

[0018] A kind of preparation method of the compound fertilizer that improves sugarcane yield provided by the invention comprises:

[0019] The base material was pulverized and sieved to obtain the first sample. Before the base material is pulverized, it is preferable to add a soil improver therein. The soil improver is preferably chemical substances such as maleic acid, polyacrylic acid, polyvinyl alcohol, etc. The soil improver can increase the gap between the base material molecules. Larger, the bacteria agent can be more fully adsorbed in the subsequent steps; after crushing, sieve, preferably with a sieve hole of 0.1cm to 2cm, the base material within this range has a good adsorption effect and will not make the sample particles too small It is not convenient for further processing.

[0020] Fermenting the microbial agent to obtain a second sample. When fermenting the microbial inoculum, the preferred method is to separately ferment different strains in the microbial ino...

Embodiment 1

[0026] Take by weighing 100kg dry bentonite and add 5kg urea wherein, 0.5kg superphosphate, 0.5kg potassium sulfate, 0.5kg calcium nitrate, 0.5kg zinc sulfate, 0.5kg gac, 0.5kg copper sulfate and 0.5kg diethyl ethyl hexanoate, wait After thorough mixing, 0.5 kg of maleic acid was added and crushed, and passed through a sieve with a diameter of 0.5 cm to obtain the first sample.

[0027] Get Bacillus megaterium, jelly-like Bacillus, Paecilomyces lilacinus, Bacillus lateralis and Bacillus subtilis each 5kg, in five petri dishes, above five strains are respectively fermented, the present embodiment selects beef extract Agar medium; the temperature of the entire fermentation process is controlled at 33°C, and the existing intelligent temperature controller is selected to regulate and control the temperature of the entire fermentation process; at the beginning of the fermentation process, the pH of the fermentation environment is adjusted to 5.5 with citric acid. No further interve...

Embodiment 2

[0031]Weigh 25kg dry rice husk, 25kg diatomaceous earth, 25kg chicken manure, 25kg duck manure and mix them, then add 5kg urea, 0.5kg superphosphate, 0.5kg potassium sulfate, 0.5kg calcium nitrate, 0.5kg sulfuric acid Magnesium, 0.5kg borax, 0.5kg zinc sulfate, 0.5kg activated carbon, 0.5kg copper sulfate and 0.5kg forchlorfenuron, after fully mixing, add 0.5kg polyacrylic acid and break it, and pass through a sieve hole with a diameter of 0.8cm to obtain the first a sample.

[0032] Get Bacillus megaterium, jelly-like Bacillus, Paecilomyces lilacinus, Bacillus sporogenes and Bacillus subtilis, each 5kg of Bacillus licheniformis, in six petri dishes, above six strains are fermented respectively, this implementation For example, pea agar medium is selected as the culture substrate; the temperature of the entire fermentation process is controlled at 36°C, and the existing intelligent temperature controller is selected to regulate and control the temperature of the entire ferment...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap