Thermosetting ink for selectively resisting electroless nickel/immersion gold

A chemical nickel gold, thermosetting technology, applied in the field of selective chemical nickel gold resistant thermosetting ink, can solve the problems of chemical nickel/gold potion pollution, reduction of nickel cylinder, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

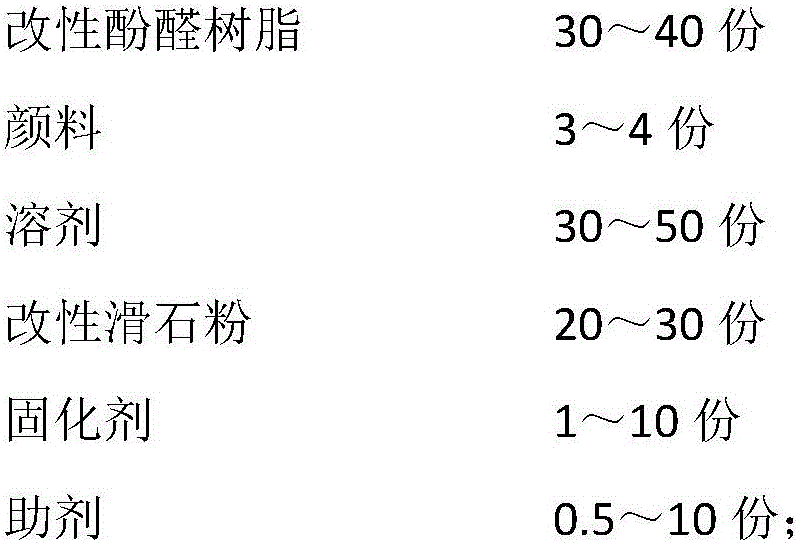

[0109] The thermosetting ink of the selective chemical resistance to nickel and gold, calculated in parts by weight, includes:

[0110]

[0111] Wherein, the mass ratio of the ethylene glycol monobutyl ether to the diethylene glycol ether in the solvent is 1:1.5; the curing agent is 2-methylimidazole; the thickener is gas phase dioxide silicon; the lubricant is polyethylene wax; the dispersant is a maleic acid-acrylic acid copolymer; the leveling agent is EL-2818 leveling agent.

[0112] The preparation steps of the thermosetting ink of the selective chemical resistance to nickel and gold are as follows:

[0113] (1) Blending: add modified phenolic resin, pigment, solvent, modified talcum powder, curing agent, auxiliary agent to the reaction kettle according to the weight part, and fully stir;

[0114] (2) Grinding: Send the blended solution in step (1) to a three-roll mill for dispersion and grinding for 2 to 3 times until the fineness is less than 10 microns. After passi...

Embodiment 2

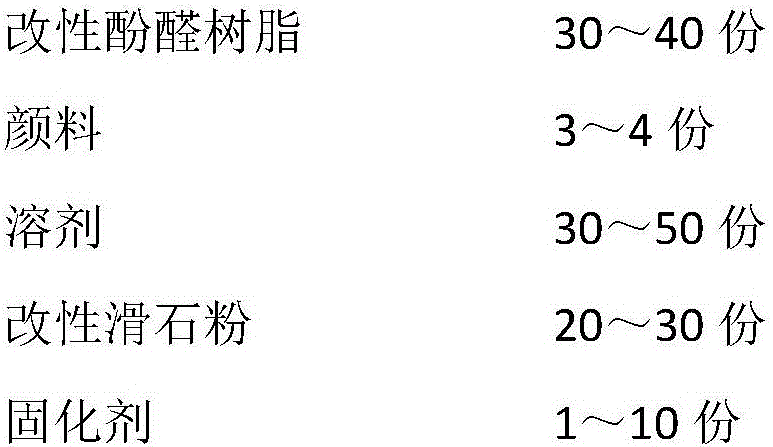

[0123] The thermosetting ink of the selective chemical resistance to nickel and gold, calculated in parts by weight, includes:

[0124]

[0125] Wherein, the mass ratio of the ethylene glycol monobutyl ether to the diethylene glycol ether in the solvent is 1:2; the curing agent is 2-methylimidazole; the thickener is gas phase dioxide Silicon; the lubricant is polyethylene wax; the dispersant is a maleic acid-acrylic acid copolymer; the leveling agent is EL-2819 leveling agent;

[0126] The preparation steps of the thermosetting ink with selective chemical resistance to nickel and gold, the preparation steps of the modified phenolic resin, and the preparation steps of the modified talcum powder are the same as in Example 1.

Embodiment 3

[0128] The thermosetting ink of the selective chemical resistance to nickel and gold, calculated in parts by weight, includes:

[0129]

[0130] Wherein, the mass ratio of the ethylene glycol monobutyl ether to the diethylene glycol ether in the solvent is 1:1.2;

[0131] The curing agent is 2-methylimidazole; the thickener is fumed silica; the lubricant is polyethylene wax;

[0132] Described dispersion agent is maleic acid-acrylic acid copolymer; Described leveling agent is EL-2820 leveling agent;

[0133] The preparation steps of the thermosetting ink with selective chemical resistance to nickel and gold, the preparation steps of the modified phenolic resin, and the preparation steps of the modified talcum powder are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com