Printed circuit board (PCB) manufacturing process

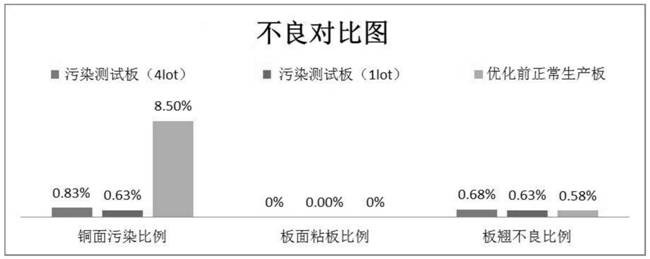

A printed circuit board and manufacturing process technology, applied in the direction of printed circuit manufacturing, printed circuit, printed circuit drying, etc., can solve the problems of PCB unit board surface pollution, out-of-tolerance expansion and shrinkage, scrap, etc., to avoid pollution, The effect of increasing the glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

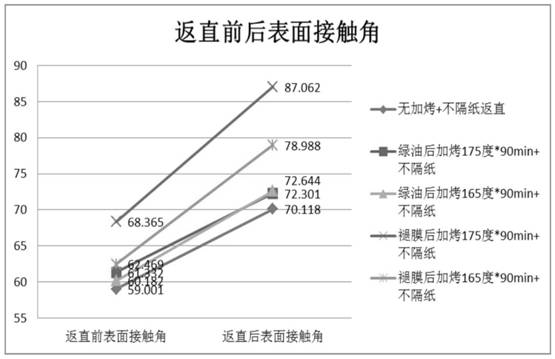

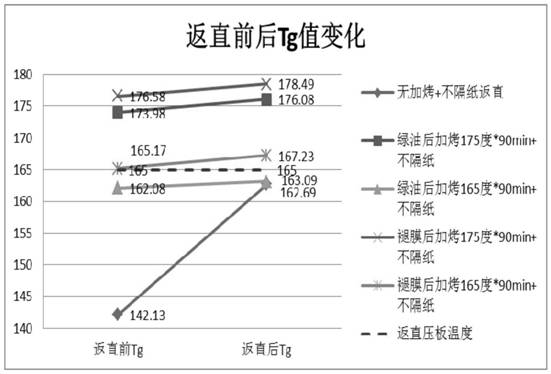

[0028] Such as Figure 1-7 As shown, in the production process of PCB printed circuit boards, in order to ensure that the expansion and shrinkage of the finished board can meet the tolerance required by customers (generally control ±3mil), after the PCB substrate is divided into PCB unit boards, a return straight baking board will be added The process releases the thermal stress in the board, so as to be able to straighten the PCB unit board, etc. where the board is bent and warped, so as to ensure that the size of the finished board meets the customer's requirements. The production process of the existing PCB printed circuit board is as follows: sold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com